1. Overview and history

Accuvon (Guangzhou) Pumps Co.,Ltd. is a Sino-foreign joint venture established in 2008. Its parent company, Germany Accuvon Pump Co., Ltd., is a world-renowned enterprise integrating R&D, production and sales of lobe pump systems, with customers all over the world's top 500 companies. The company has been committed to one-stop solutions for efficient transmission of complex fluids for many years. It has strong technical advantages in the industry and has gradually become the industry leader.

2. Products and markets

The company mainly produces rubber lobe pumps, stainless steel lobe pumps, mobile drainage pump trucks, hand cart pump , lobe pump sealed sewage lifting devices, online lobe pump vacuum sewage suction units for high-speed rail and other related equipment. Products are widely used in wastewater environmental protection, petrochemical industry, rail transit and other fields. The company relies on its huge technical advantages to tailor targeted solutions for customers with different needs.

3. R&D and technological innovation

For the core component - elastomer rubber rotor, the company has set up a precision research and development department to continuously develop various rubber rotors, striving for the best performance and longest service life; the company has cooperated with the Chinese Fluid Society, South China University of Technology, Nanchang University, Jiangsu University, etc. Industry authorities and universities have launched long-term and in-depth cooperation to overcome difficulties in integrating fluid and material CFD simulation, adaptive adjustment, pumping monitoring, pumping segmentation and other advanced algorithms, as well as intelligent technologies such as calculated resistance and profile AI. Has obtained more than 50 national patents

4. Equipment and facilities

The factory covers an area of 20,000 square meters, with 12 departments and 12 production workshops, with an annual output of more than 2,000 lobe pumps and system units; the production workshop has a variety of intelligent machining centers, three-dimensional coordinate inspection machines, lobe pump testing stations, etc. High-precision production equipment; the inspection workshop has a variety of precise inspection equipment such as paint, noise, vibration, flaw detection, etc. Mature technology and comprehensive technology.

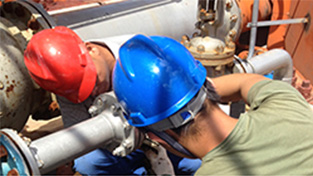

5. Production process

In order to ensure that the product operates around the clock, the company's design department designs drawings based on the product application process; the production department uses German specially trained technicians as the backbone to assist intelligent machinery to ensure accurate processing and ensure that the product can adapt to harsh working conditions.

6.Quality control

The company has passed multiple management system certificates such as ISO9001, ISO14001, and ISO45001, as well as high-tech enterprise certificates. The company's front-end strictly implements various industry standards such as API676 , SH/T 3151-2013 , ISO9001 , DIN, EN, etc. to ensure that products from raw materials to semi-finished products to finished products will undergo comprehensive, meticulous and systematic testing , and enter the assembly process after passing the test. ; Back-end quality testing includes performance, hydraulic, pneumatic, NPSHR , sound and vibration, etc., and further testing can be conducted according to customers’ special requirements (magnetic powder, dye penetrant, traceability and material identification, etc.) to maximize satisfaction Customers’ individual needs.