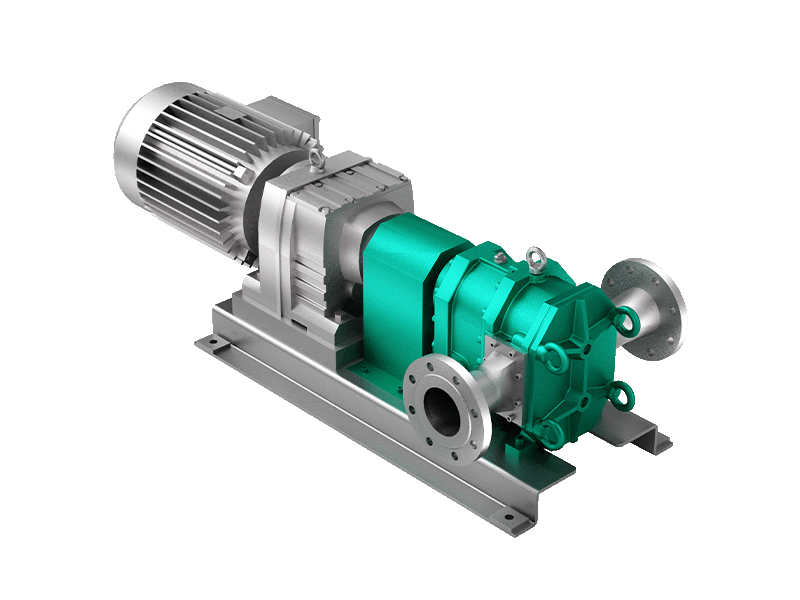

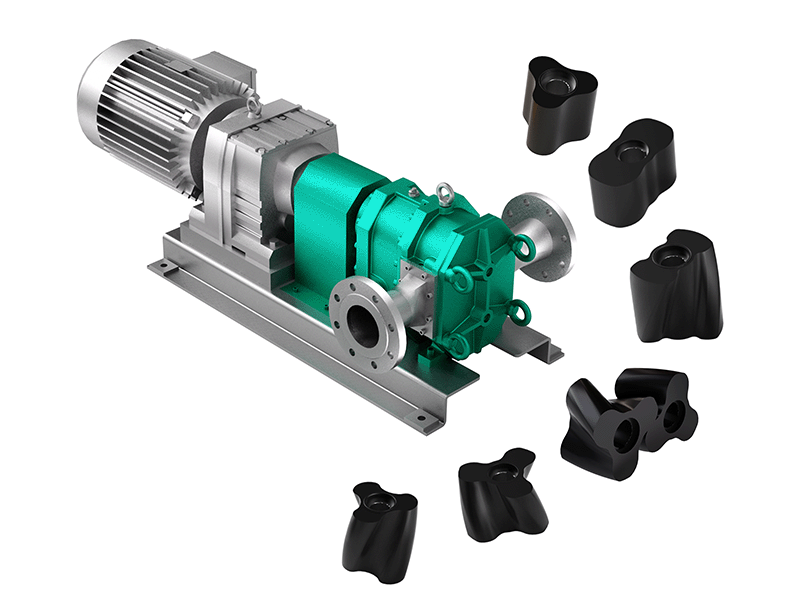

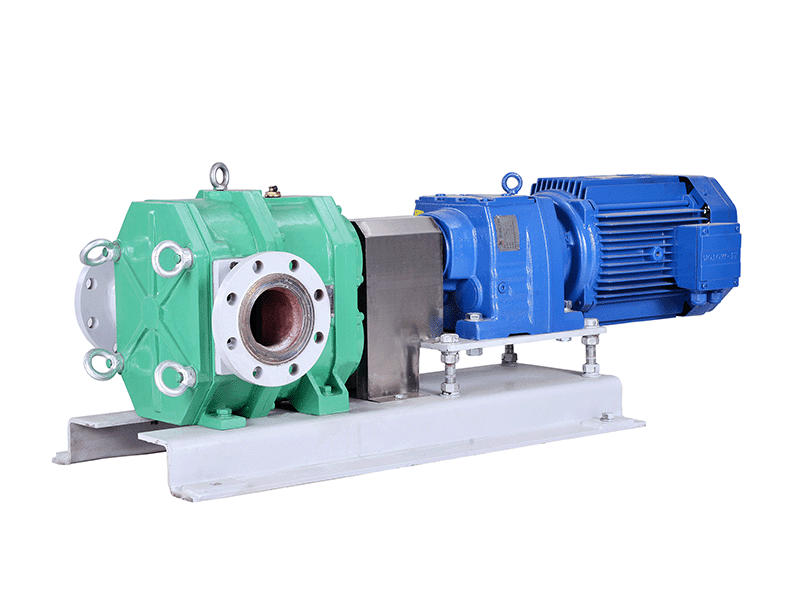

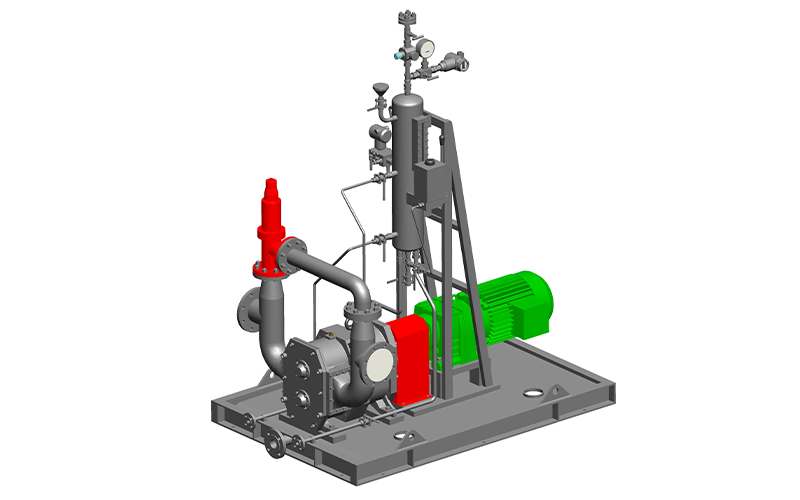

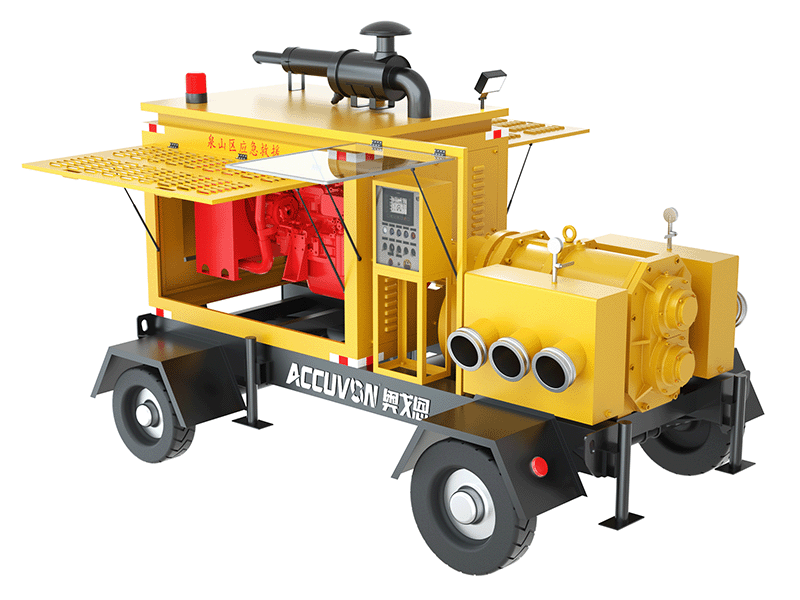

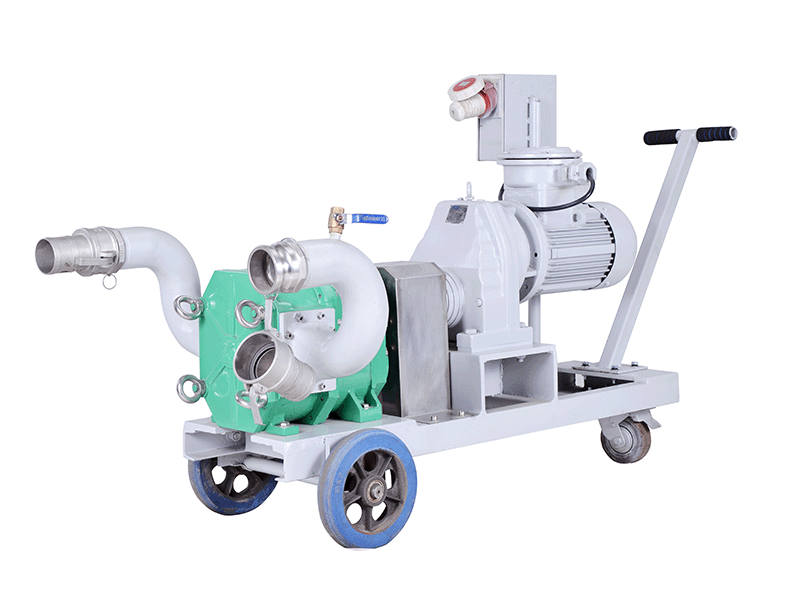

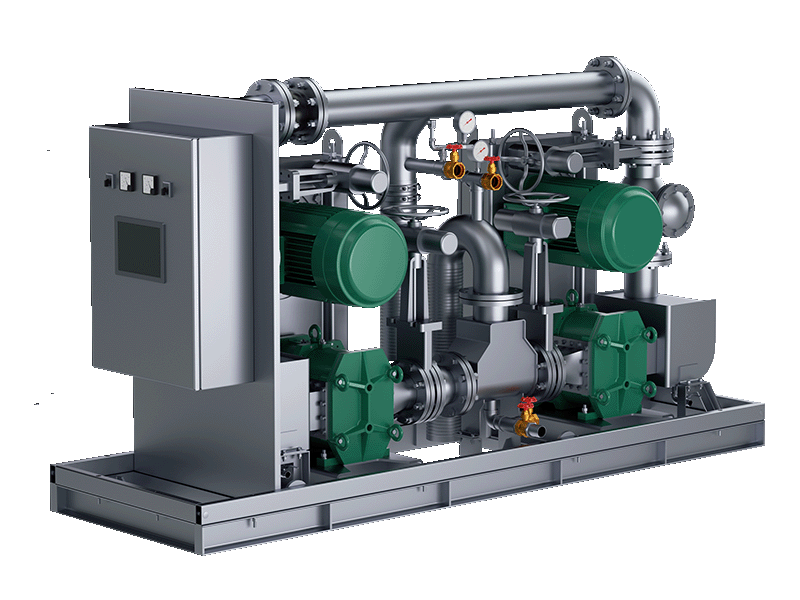

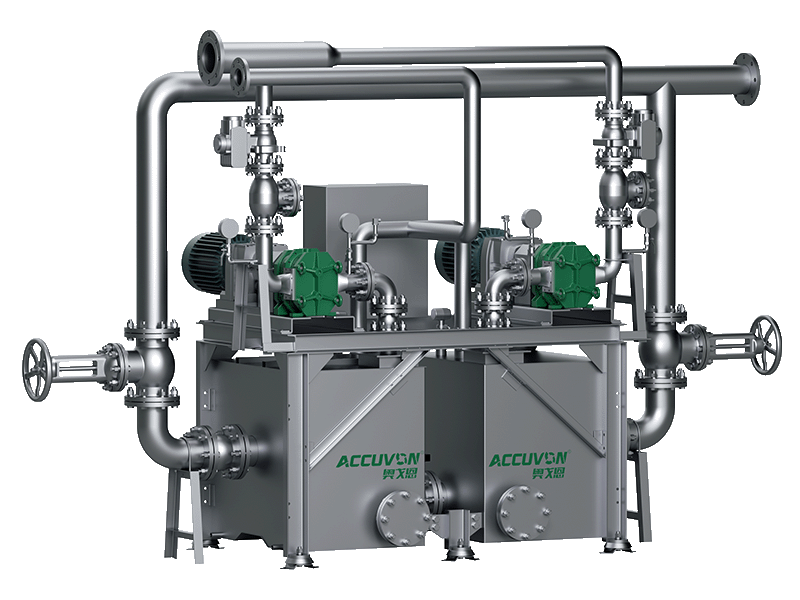

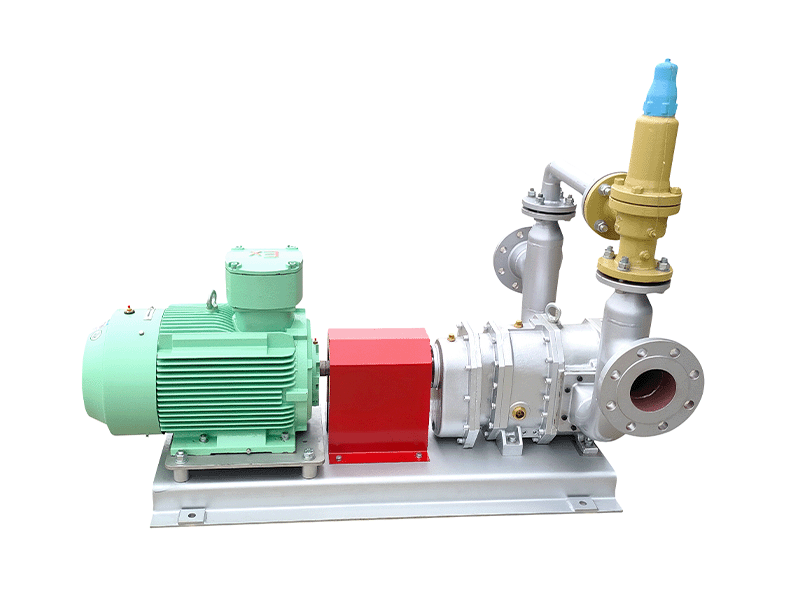

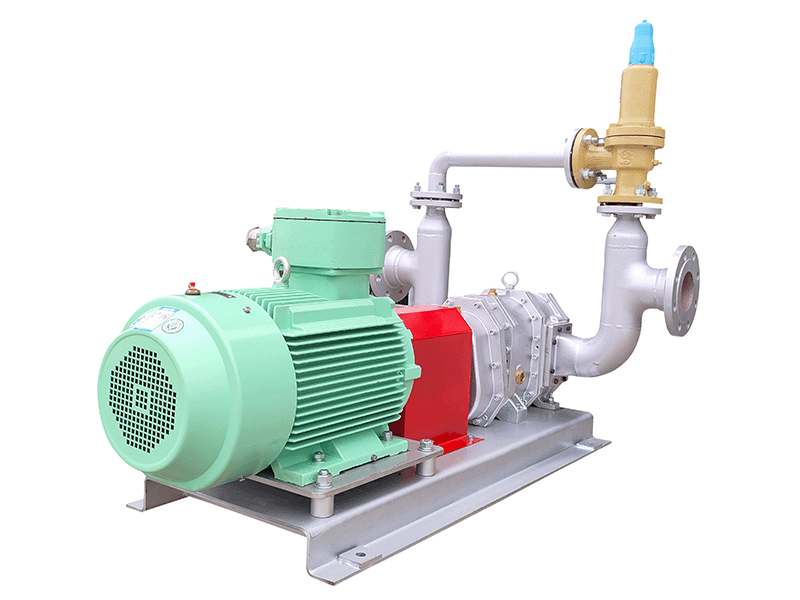

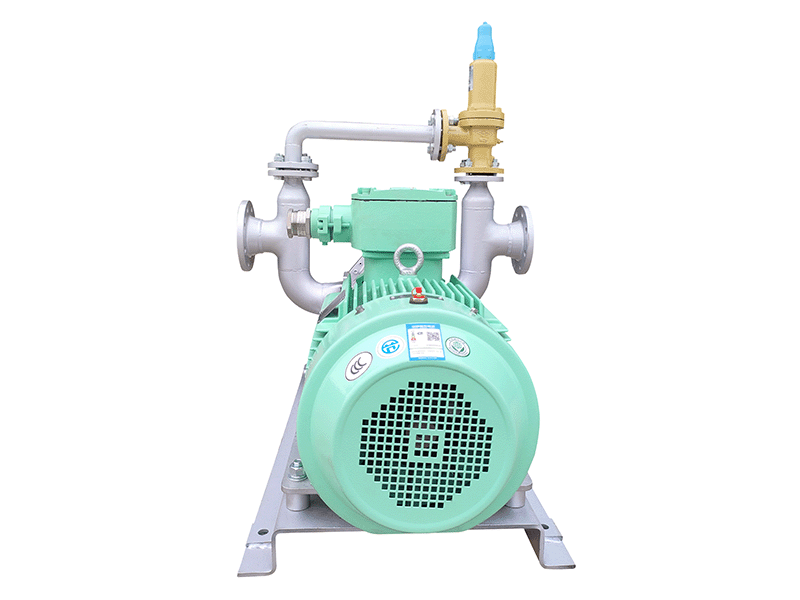

The ACCUVON lobe oil pump(industrial lobe pump)is a lobe rotor pump that complies with the API 676 standard. It is a pump specially designed for use in the petroleum and petrochemical industry. This standard is a specially designed pump promulgated by the American Petroleum Institute (API). Transfer pumps for the petroleum and petrochemical industries. These pumps are designed and manufactured taking into account the particularities of petroleum and petrochemical products, such as high temperature, high pressure, corrosiveness, etc. These pumps usually have the characteristics of high efficiency, stability, corrosion resistance, high temperature resistance, and good sealing performance to meet the special needs of the petroleum and petrochemical industry. The design and manufacturing strictly comply with relevant international standards and industry specifications to ensure safe and reliable operation.

The API 676 standard specifies the design, manufacturing and testing requirements for lobe rotor pumps to ensure that they can operate stably and reliably in the harsh working environments of the petroleum and petrochemical industry. These requirements typically cover the following areas:

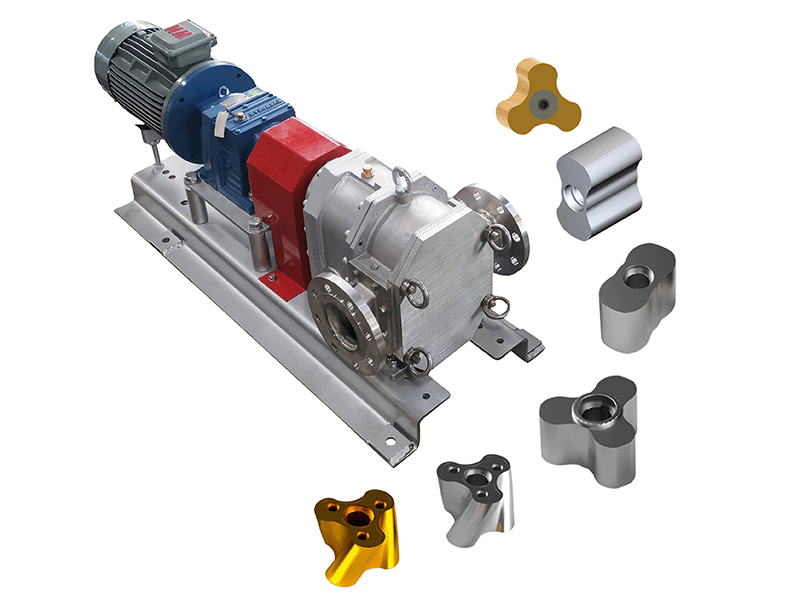

- 1. Material selection: Strict requirements are placed on the material performance and corrosion resistance of the pump to adapt to the particularity of the medium.

- 2. Design requirements: Including requirements on the pump's structural design, seal design, axial and radial force bearing capacity, etc., to ensure that the pump can operate stably and be used for a long time.

- 3. Performance requirements: including requirements for flow, head, efficiency and other performance indicators to ensure that the pump can meet process requirements.

- 4. Testing requirements: Conduct comprehensive performance testing and quality control on the pump to ensure that the performance and quality of the pump meet standard requirements.

- 1. Strong adaptability: These pumps are suitable for handling liquid media of various viscosities, temperatures and pressures, and can cope with different working conditions in the petrochemical production process.

- 2. Corrosion resistance: Use corrosion-resistant materials and special coatings such as stainless steel, alloys, etc. to resist corrosive media such as crude oil and salt water.

- 3. High temperature resistance: Pump components are usually able to withstand high temperatures to adapt to the high temperature environment in the chemical production process.

- 4. High efficiency: The lobe rotor pump has efficient delivery performance and can provide stable and efficient liquid delivery, which helps to improve production efficiency and reduce energy consumption.

- 5. High stability: stable operation, able to work continuously for a long time, and adapt to changes in the production environment.

- 6. Strong reliability: Design and manufacturing comply with international standards and industry specifications, and undergo strict quality control and testing to ensure the reliability and safety of the pump.

- 7. Energy saving and environmental protection: Some rotor pumps adopt advanced energy-saving design and technology to reduce energy consumption and production costs, while also helping to reduce the impact on the environment.

In general, the lobe rotor pump used in the petrochemical industry has the characteristics and advantages of corrosion resistance, high precision, strong adaptability, high temperature resistance, high efficiency, good sealing, and strong reliability, providing a reliable solution for petrochemical production. Liquid delivery solutions.

Rotor pumps used in the petrochemical industry play an important role in a wide range of applications, mainly including the following aspects:

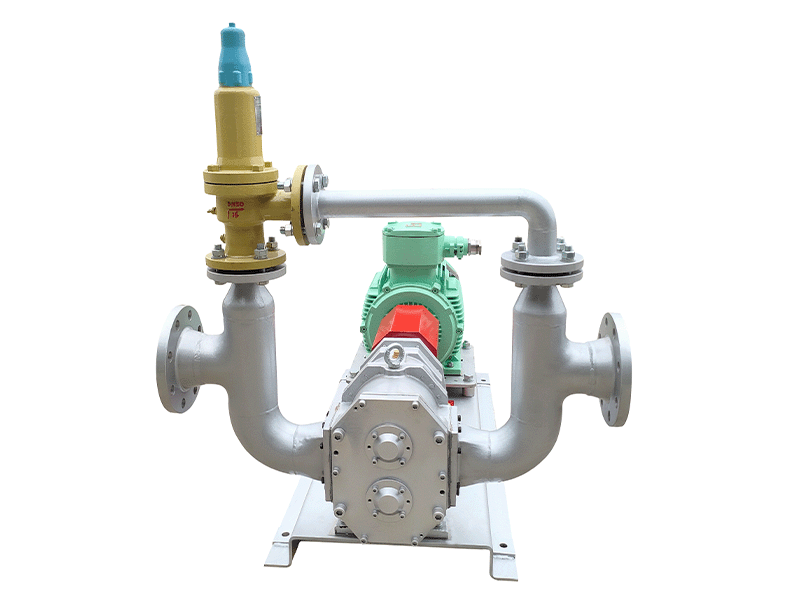

- 1. Crude oil production and transportation: Rotor pumps are used to lift crude oil from oil wells to the surface and transport the crude oil to refineries or other processing facilities, such as separation tanks, storage tanks, or directly to pipelines. They are able to handle high viscosity crude oil and ensure stability and reliability of the transfer process.

- 2. Refinery processing process: In refineries, rotor pumps are used to transport various refining products, including gasoline, diesel, kerosene, aviation fuel, etc. These pumps are able to handle liquids of varying viscosities and densities and ensure precise delivery of the product.

- 3. Chemical product production: Rotor pumps also play an important role in the chemical production process and are used to transport various chemical raw materials and products, such as solvents, acid and alkali solutions, polymers, solutions, etc.

- 4. Liquid reaction process: During the liquid reaction process, the rotor pump is used to transport reaction materials, intermediates and reaction products to ensure the smooth progress of the reaction process.

- 5. Storage and transportation: Rotor pumps are used for loading and unloading liquids in storage facilities, and for liquid transportation in oil pipelines. They ensure safe storage and efficient transportation of petrochemical products.

- 6. Environmental protection and wastewater treatment: In the petrochemical industry, rotor pumps are also used in environmental protection fields such as wastewater treatment and sludge transportation to transport wastewater and sludge to treatment facilities to protect the environment.

In summary, rotor pumps used in the petrochemical industry have important applications in crude oil production, refining processing, chemical product production, liquid reaction processes, storage and transportation, and environmental protection fields, providing reliable solutions for petrochemical production. Liquid delivery solutions.