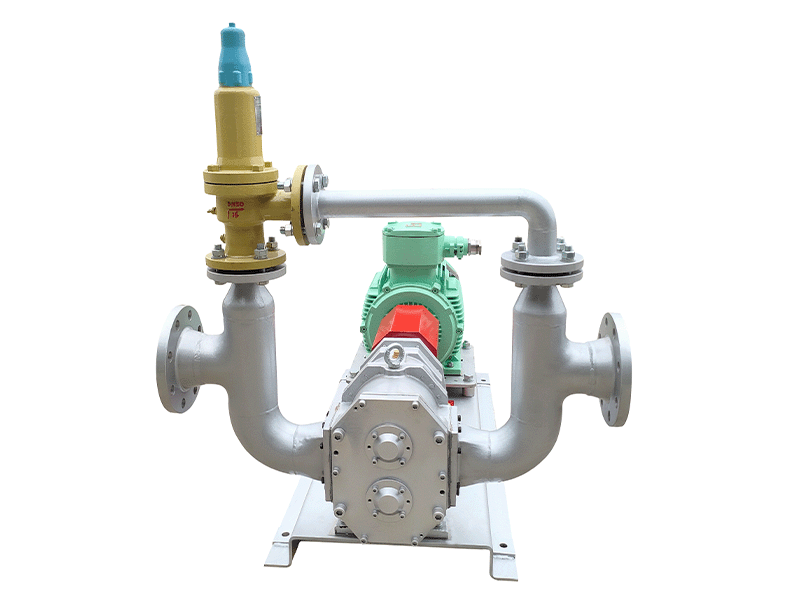

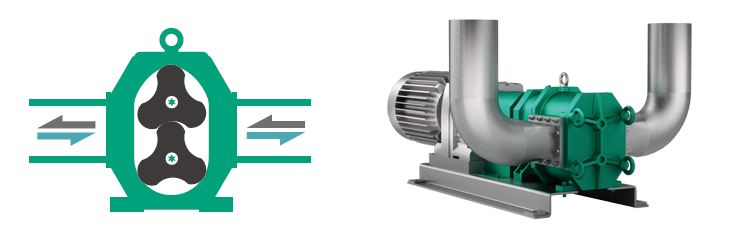

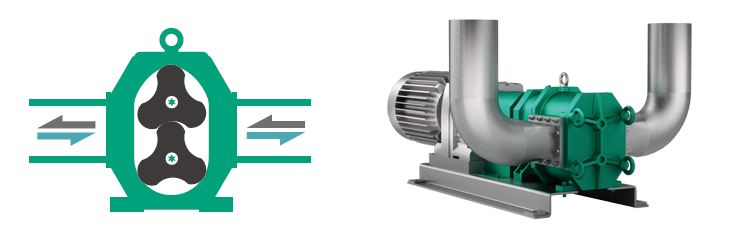

Rotary lobe pumps are not sensitive to dry running and are self-priming positive displacement pumps. The synchronized rotation of the rotor pair and the increasing suction chamber create a vacuum on the priming side of the pump. This vacuum draws the liquid into the pump chamber. The pumped medium is conveyed past the pump wall into the pressure area by the rotors. The synchronized rotation of the rotor pair and the decreasing pressure chamber create an overpressure on the discharge side of the pump. The flow direction can easily be reversed by changing the direction of rotation.

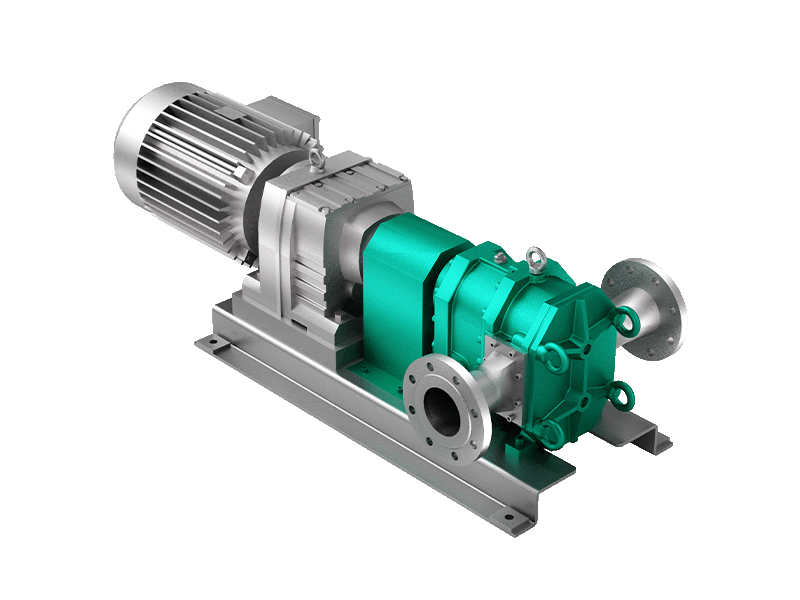

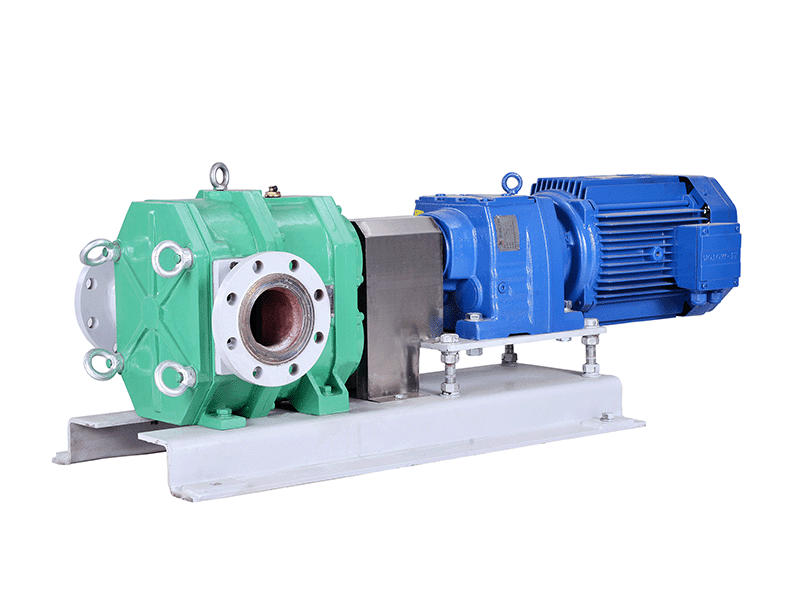

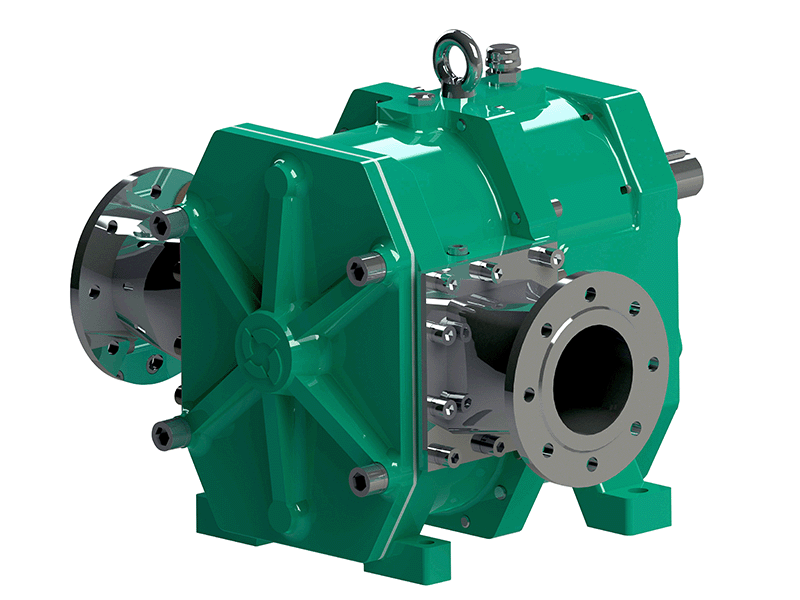

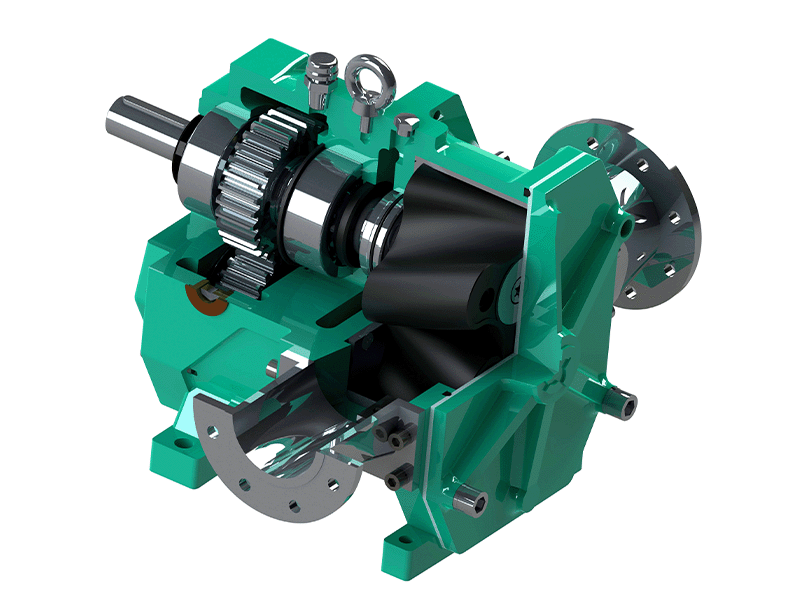

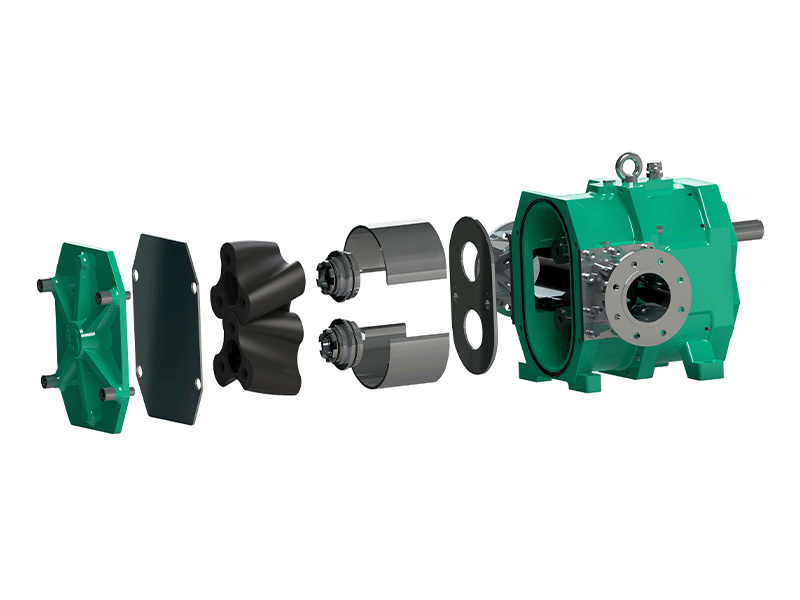

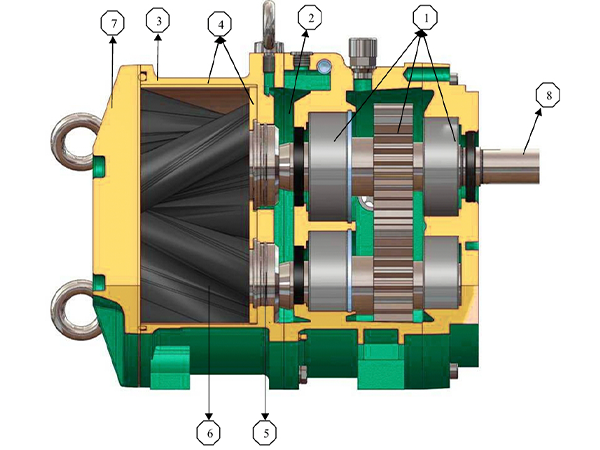

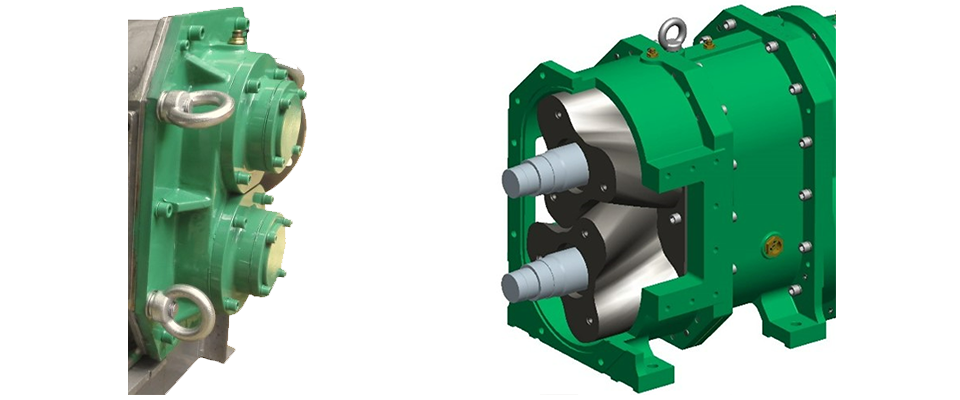

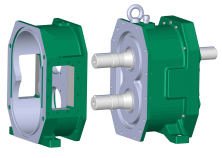

The Components of the ACCUVON Rotary Lobe

- 1. Bearing and timing gear

- 2. Intermediate chamber

- 3. Casing in Block design

- 4. Axial and radial casing liners

- 5. Shaft seals

- 6. Rotary Lobes

- 7. Quick-release-cover

- 8. Non-wetted shafts

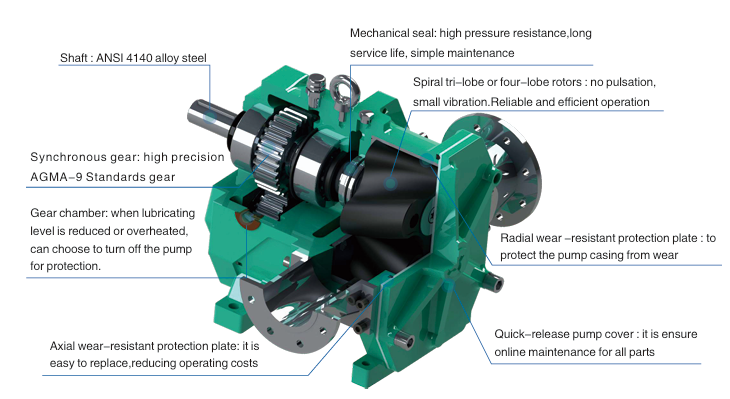

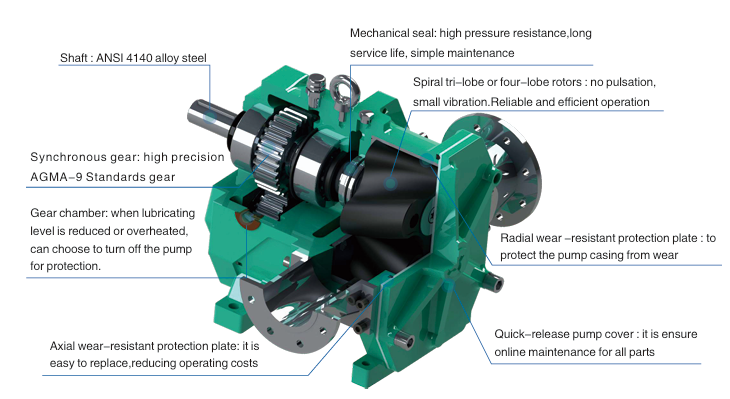

The structural design of the Accuvon rotary lobe pump is very simple, and all models of the pump retain a simple design style. The quick-release pump cover provides convenience for the maintenance of the pump without dismantling the pipeline.

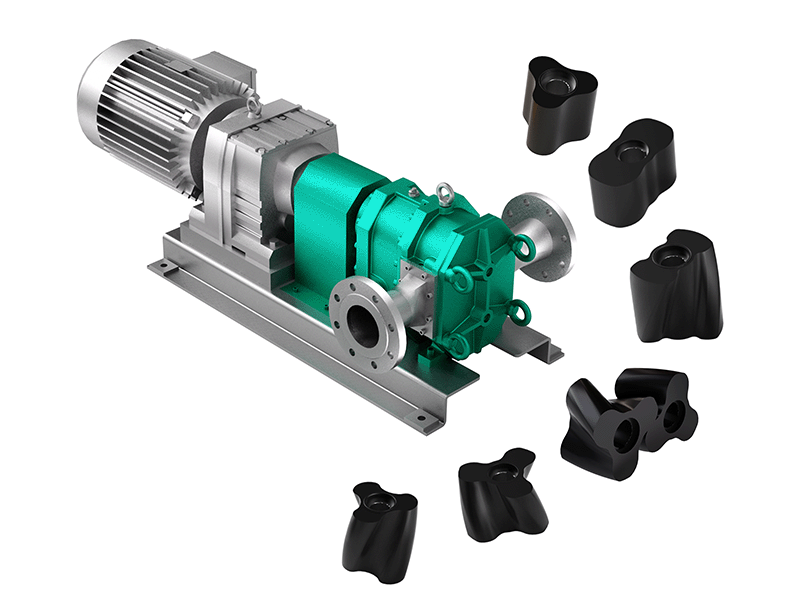

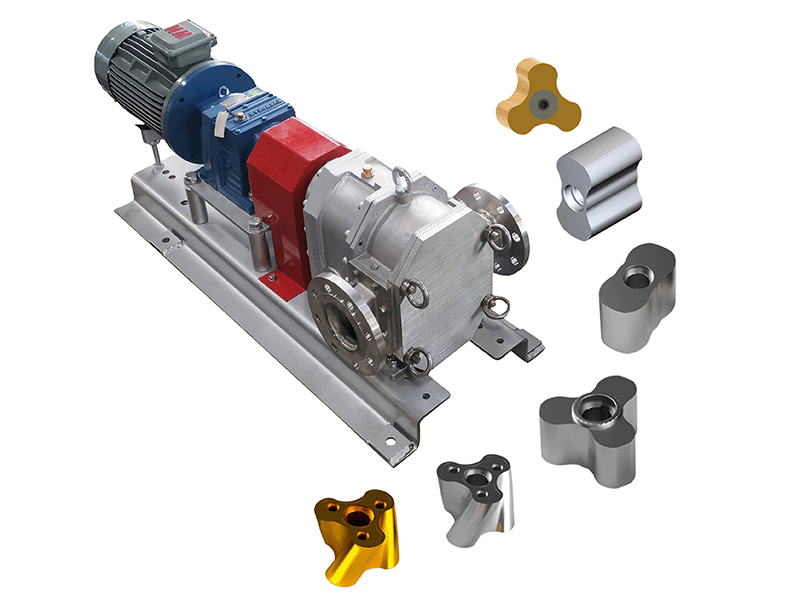

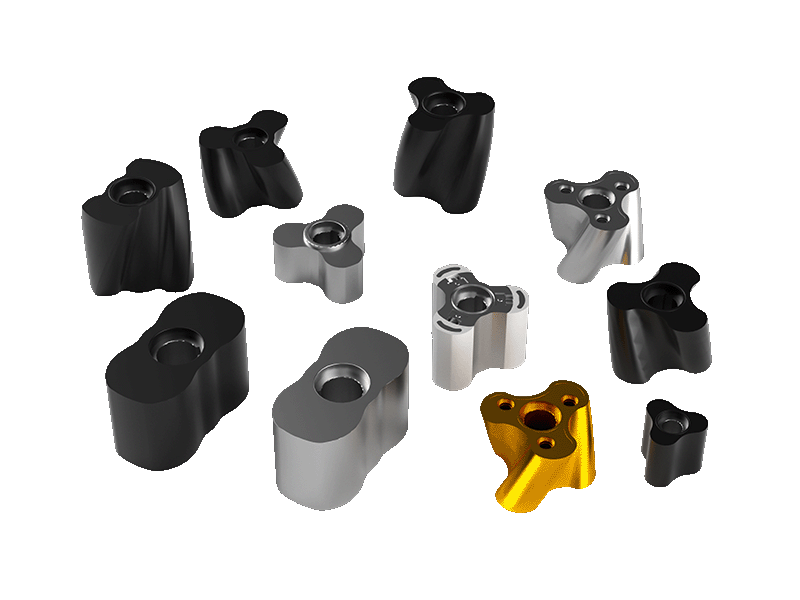

We offer a range of linear and screw rotors differentiated by geometry and material. Whether made of NBR, EPDM, FKM, PTFE, stainless steel, steel or another material, we offer a suitable rotor for your application.

- NBR, versatile use, resistant to oil

- SBR, resistant to abrasion and aging

- FPM, high resistance to oil and chemicals

- EPDM, very versatile for chemicals

- PTFE, for extreme chemical and temperature stress

- stainless steel rotors

Multi-Faceted And Safe The Accuvon Seals

In order to protect the gear unit or the atmosphere from the pumped medium, suitable shaft seals are very important. Accuvon offers different mechanical seals. Several supply systems for the seals can be selected.

Quality And Diversity Down To The Last Detail

Seal faces, elastomers and seal casings made of different materials make sure that the most resistant and durable materials are used for each pumped medium. All seal types are available as a cartridge unit and are simply replaced through the quick-release cover of the pump.

- + Single-acting and double-acting mechanical seals

- + available as a cartridge unit

- + seals are available in different versions and materials

- + special rotating holding bushes for fibrous media

- + the seals can be replaced very easily through the quick-release cover

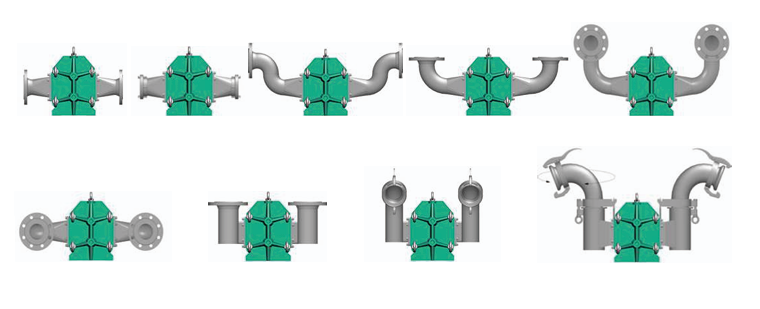

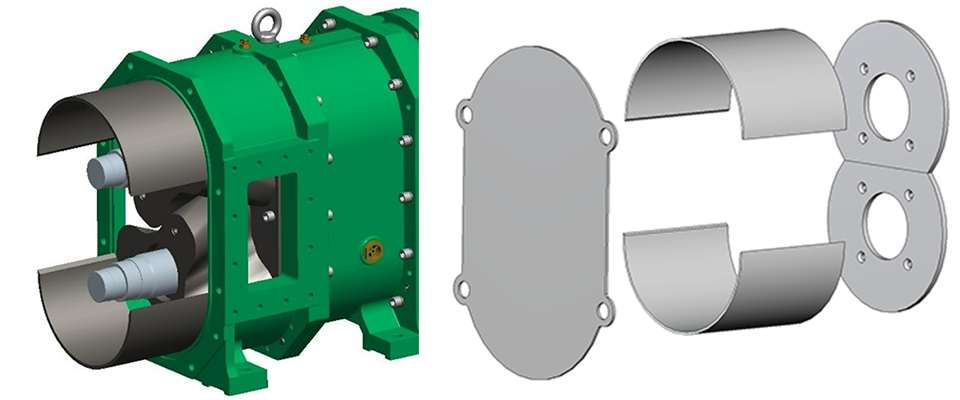

Each rotary lobe pump is equipped with a non-segmented pump and gear casing. This design reflects our high quality standard and guarantees long service life with ease of maintenance. The pump casing can be manufactured in cast iron, cast steel, stainless steel, duplex steel.

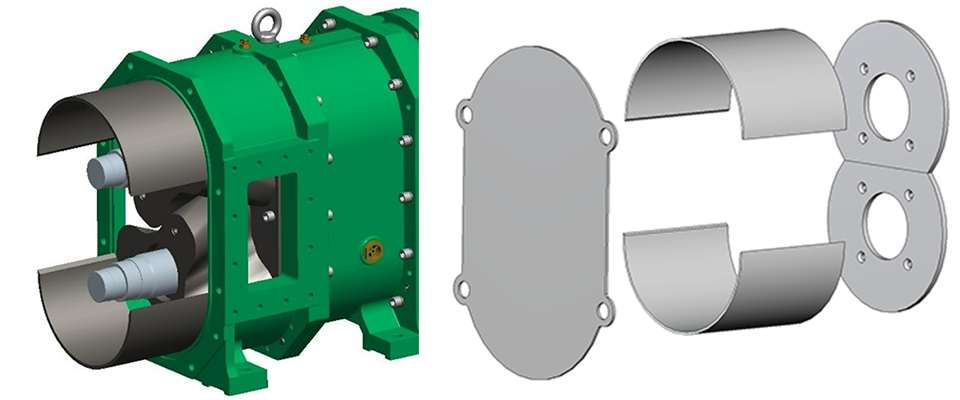

The pump casing is made of a single cast part and manufactured to narrow tolerances. On the face sides – and optionally on the radial sides as well – exchangeable casing protection plates are inserted to minimize wear and the associated replacement part costs. The entire pump casing is also available with a hardened surface to make it extremely abrasion-resistant.

Upon request, the inside of the pump casing is lined with a casing protection which protects the pump casing from wear caused by solids (e.g. sand or stones). In case of wear, the casing protection can easily be replaced.

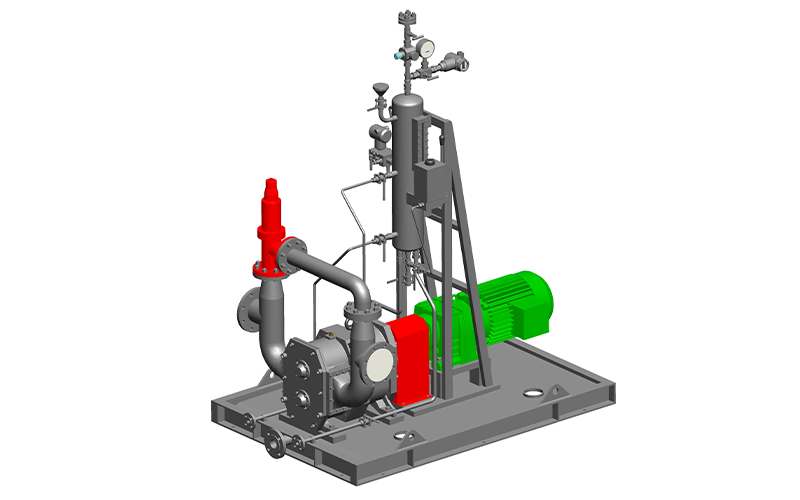

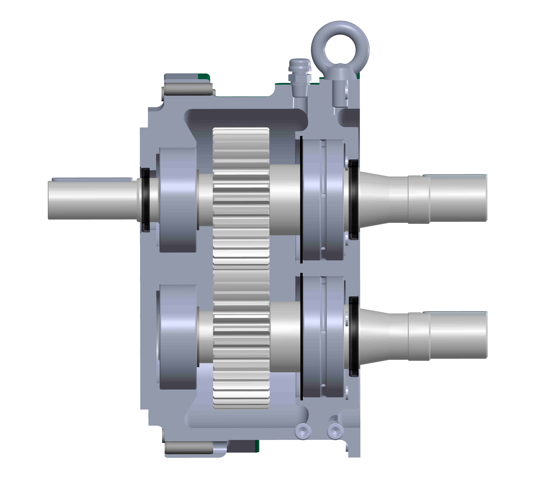

Oil-Filled Intermediate Chamber

|

The oil in the large-volume intermediate chamber cools and lubricates the seals. The intermediate chamber protects the gear unit from pumped medium leaking in if the mechanical seal is defective. Escaping fluid flows into the intermediate chamber without pressure and can leak out through the overflow opening. Highest degree of operational safety for your plant.

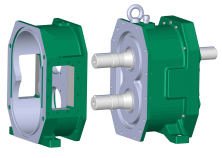

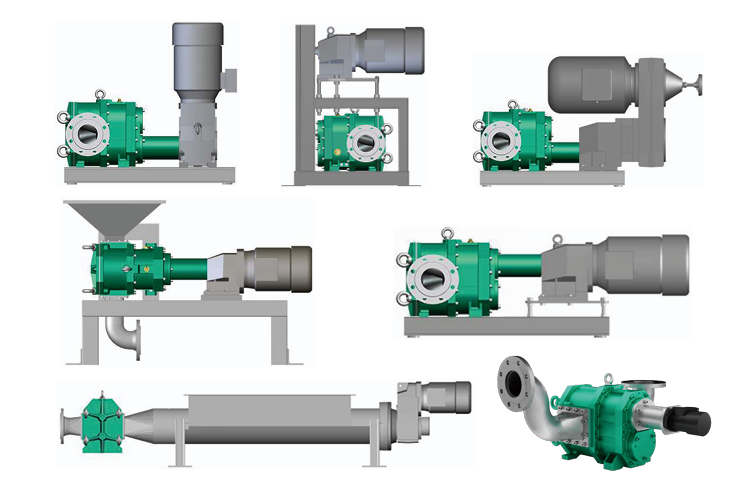

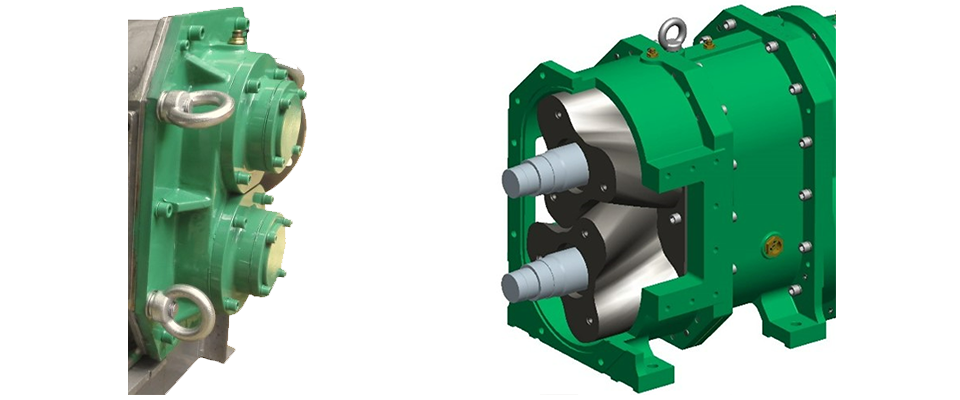

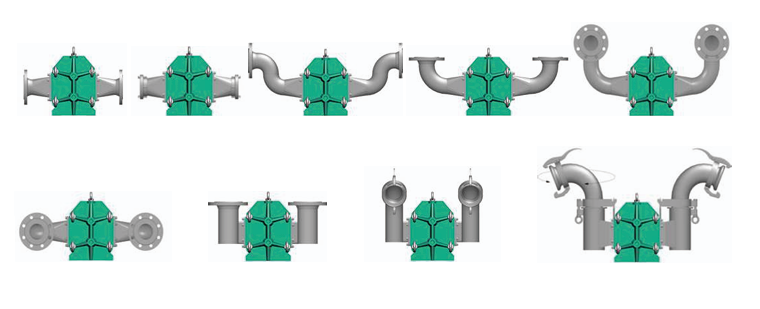

Single And Double Supports

|

There are two support methods for the pump cover of Accuvon rotary cam pump: single support structure and double support structure;

Single support structure: usually used in scenarios with relatively low pressure or pump types with relatively short pump shafts to ensure the stability of the pump during operation and the convenience of maintenance;

Double support structure: usually used in scenarios with relatively high pressure or pump types with relatively long pump shafts.To ensure the stability of the pump during high-pressure operation;

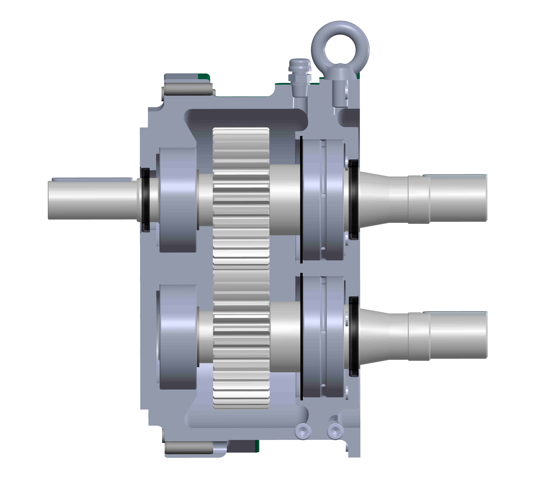

The rotors are synchronized and precisely guided over the carrier shafts by two spur gears, through which a limited dry running of the pump is possible. The timing gear and carrier gear unit represent a single sealed component. The high quality and extremely sturdy gear wheels ensure even, smooth operation, as well as long service life.

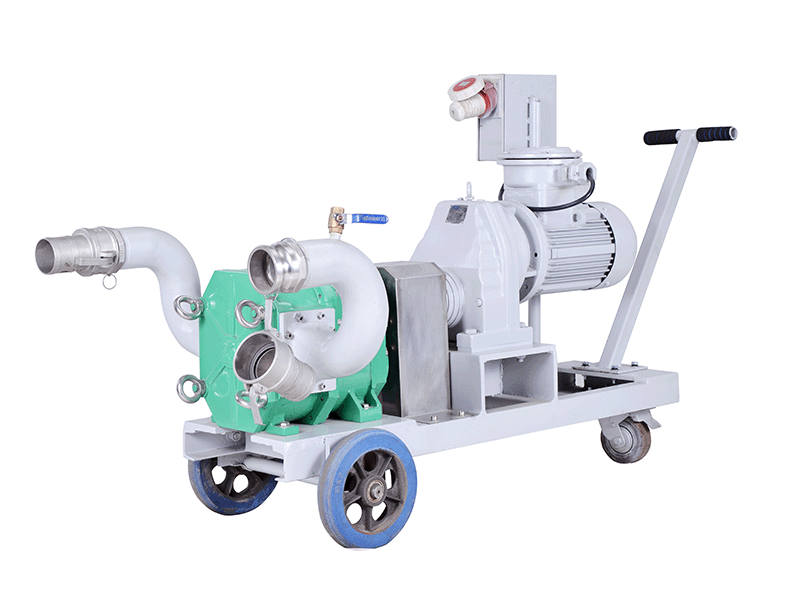

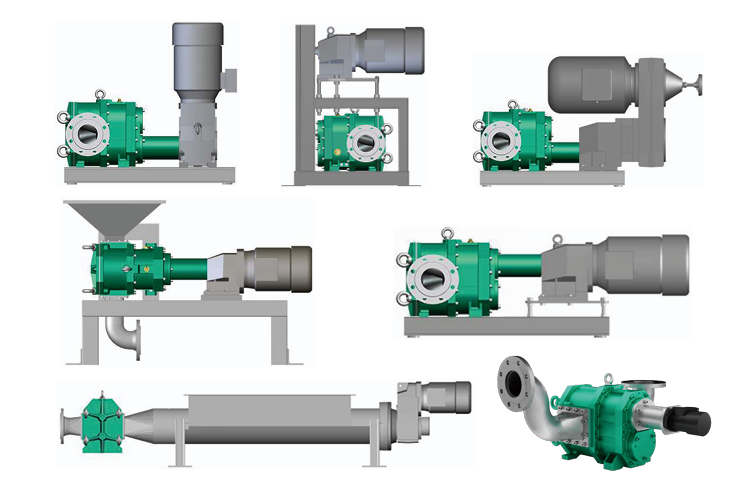

Different motors can be used for driving the rotary lobe pump. Please find a small selection here.

- + Electric motor

- + Combustion engine

- + PTO

- + Hydraulic motor

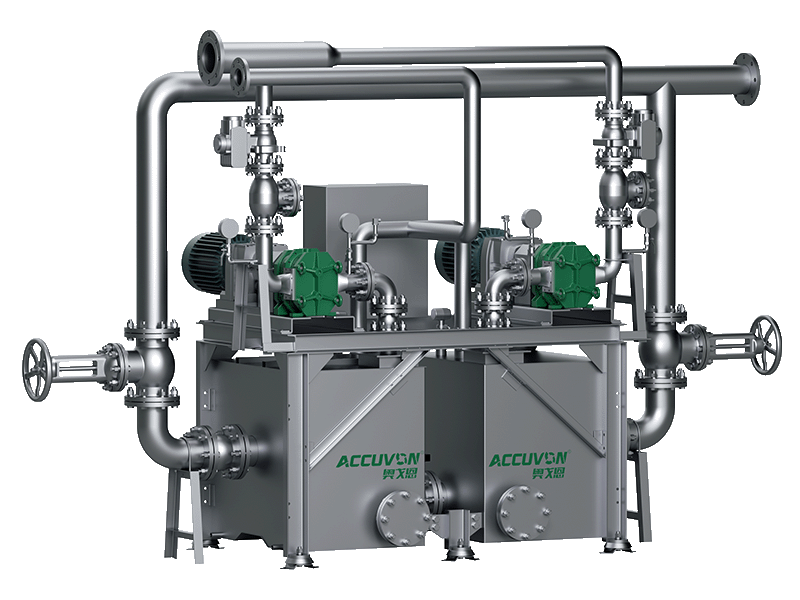

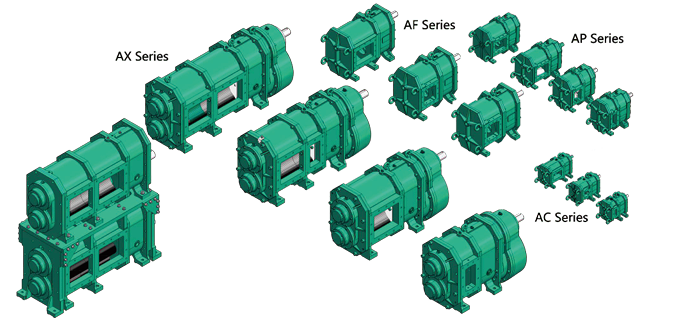

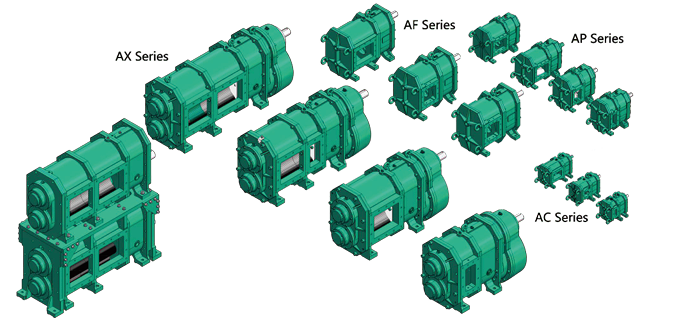

4 Series with 16 models constitute the perfect product line of Accuvon rotary lobe pumps. The maximum flow rate is up to 3200m³/h, the maximum pressure is up to 2.5MPa and the flow rate of 5000m³/h is under development. The modular design of the pump makes the same commonality of the same series and increases the universal interchangeability of parts.

| Series |

Model |

Stroke

Volume |

Flow |

Max.

Pressure |

Adwice |

Speed |

Standard |

Optional flange |

Power |

| l/r |

m³/h |

Mpa |

rpm |

rpm |

mm |

mm |

Kw |

| AC |

AC25 |

0.196 |

1~5 |

1.2 |

≤350 |

25~650 |

DN25 |

DN20/DN40 |

0.75~3 |

| AC50 |

0.392 |

6~8 |

1.0 |

≤350 |

25~650 |

DN50 |

DN40/DN65 |

1.1~5.5 |

| AC75 |

0.588 |

9~15 |

0.6 |

≤350 |

25~500 |

DN50 |

DN65/DN80 |

1.5~5.5 |

| AP |

AP80 |

1.125 |

18~25 |

1.8 |

≤350 |

25~500 |

DN80 |

DN65/DN100 |

2.2~22 |

| AP100 |

1.857 |

28~38 |

1.4 |

≤350 |

25~500 |

DN100 |

DN80/DN125 |

3~22 |

| AP120 |

2.864 |

40~60 |

1.0 |

≤350 |

25~500 |

DN100 |

DN80/DN125 |

5.5~22 |

| AP140 |

3.714 |

60~80 |

0.6 |

≤350 |

25~500 |

DN125 |

DN100/DN150 |

7.5~22 |

| AF |

AF125 |

4.566 |

85~110 |

1.6 |

≤350 |

25~500 |

DN125 |

DN100/DN150 |

11~75 |

| AF150 |

6.828 |

120~160 |

1.2 |

≤350 |

25~500 |

DN150 |

DN125/DN200 |

15~75 |

| AF200 |

9.456 |

170~220 |

0.8 |

≤350 |

25~500 |

DN200 |

DN150/DN250 |

15~75 |

| AX |

AX250 |

12.5 |

230~300 |

2.5 |

≤350 |

25~650 |

DN250 |

DN200/DN300 |

22~450 |

| AX300 |

25 |

300~750 |

1.0 |

≤350 |

25~650 |

DN300 |

DN250/DN350 |

22~600 |

| AX350 |

37.5 |

800~1200 |

0.6 |

≤350 |

25~650 |

DN350 |

DN300/DN400 |

30~600 |

| AX450 |

50 |

1300~1600 |

0.4 |

≤350 |

25~650 |

DN450 |

DN400/DN500 |

30~600 |

| AX350D |

75 |

1600~2400 |

0.6 |

≤350 |

25~650 |

DN350*2 |

|

55~600 |

| AX450D |

100 |

2600~3200 |

0.4 |

≤350 |

25~650 |

DN450*2 |

|

55~600 |

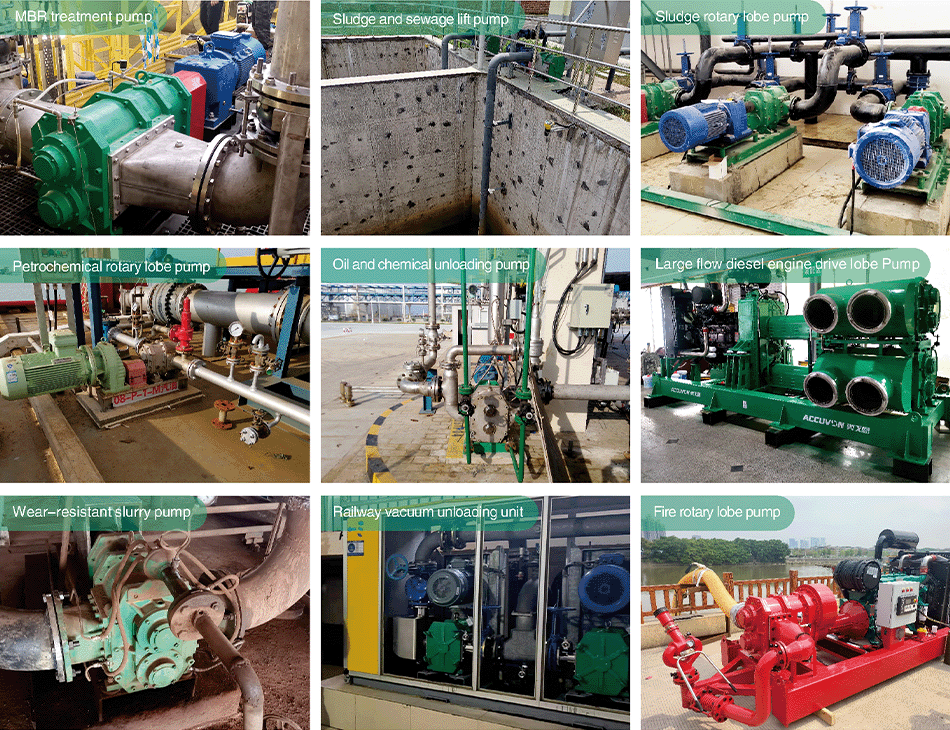

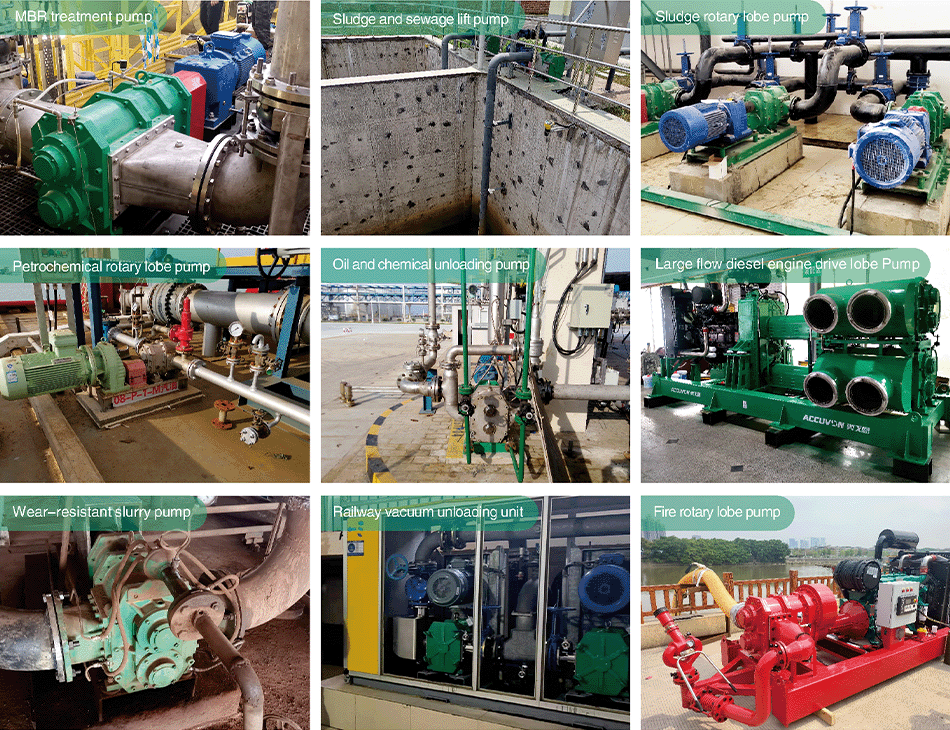

Sewage oil and sewage lifting pumps, oil and chemical products unloading pumps, tank bottom oil pumps, waste oil recovery pumps, warehouse and line sweeping pumps, oil sludge delivery pumps, petroleum skid installation systems, gas-liquid mixed pumps etc. (Common media: gasoline, diesel, jet fuel, naphtha, heavy oil, fuel oil, crude oil, residual oil, methanol, ethanol, polyols, concentrated sulfuric acid, liquid caustic soda, phosphoric acid, sludge, dirty oil, grease, lubricating oil, Viscous oil, asphalt, catalyst, oily sewage, domestic sewage, accident water, rainwater, etc.)

Sludge feed pump, sludge return pump, excess sludge pump, floating sludge pump, concentrated sludge pump, bridge type suction machine sand pump, sewage sludge lift pump, landfill leachate lift pump, MBR treatment (negative pressure suction pump, pickling and alkali washing backwash pump), mud cake pump, lime slurry dosing pump, powdered activated carbon dosing pump, dosing metering pump, etc.

Fine chemicals (chemical raw materials, chemical additives, adhesives, emulsion explosives, 107 glue, silicone oil, glycerin, coatings, resins and polymers, dyes, gypsum, iron white powder, etc.); daily chemicals (LAS, AES, AOS, MES, K12, sorbitol, skin cream, nutritional cream, cosmetics, dental tone, facial cleanser, lotion, shampoo, body wash, liquid soap, soap, detergent, laundry powder slurry, etc.)

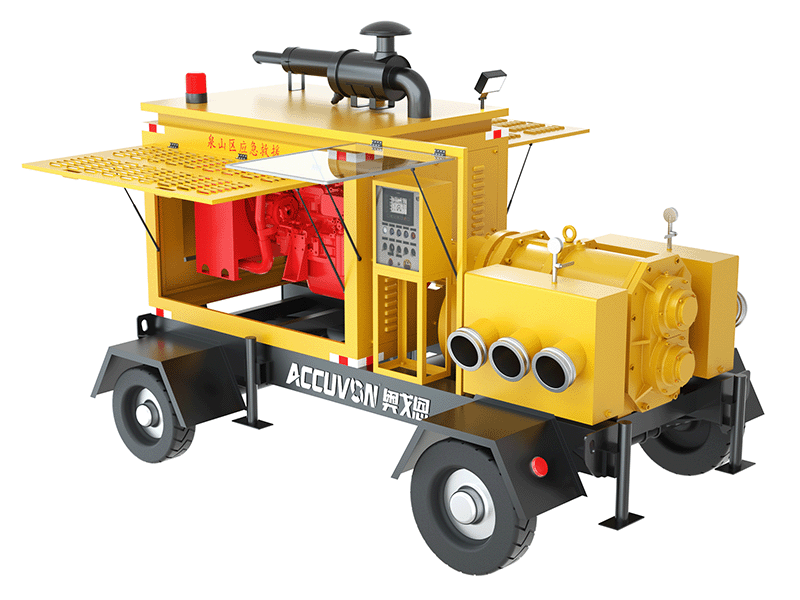

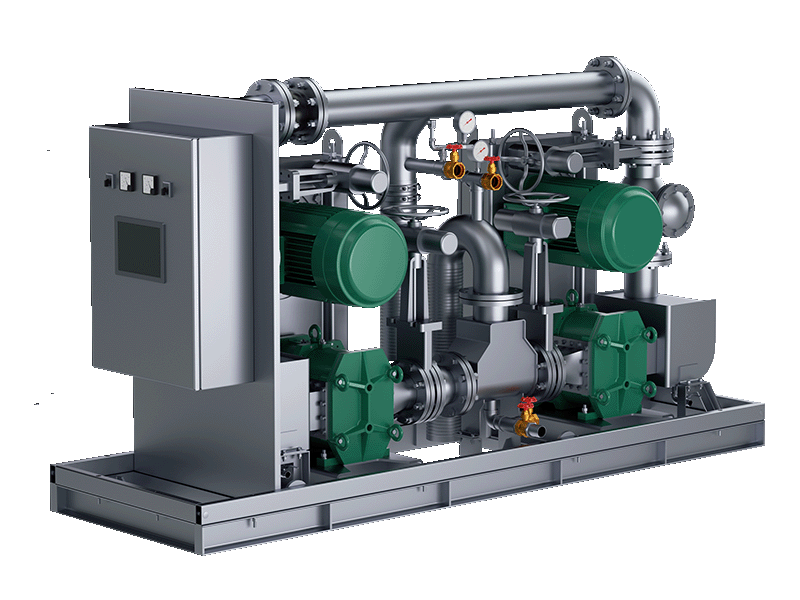

Vacuum sewage system, cam type airtight pumping station, cam type airtight sewage lifting device, On-line rotary lobe pump unit (vacuum unloading system of railway train station), vacuum discharge system for railway stations, vacuum discharge system for subway, etc.

Kitchen waste, landfill leachate, expired food, animal manure (pig manure delivery pump, cow manure delivery pump), various organic matter, etc.

Positive and negative electrode material slurry, conductive additives, battery slurry, vacuum defoaming, stirring, coating process, etc.

Bilge wastewater, domestic sewage, waste oil, sludge, fuel oil, etc.

Pulp, additives, latex, etc.

Yogurt, whipped cream, ice cream, cheese, etc.

Beer, diatomaceous earth, wort, yeast, soft drinks, fruit concentrates, juice drinks, etc. Confectionery:

syrup, cream, chocolate, etc.

Animal offal and blood, animal meat, etc.

Tomato paste, fruit puree, vegetable paste, pudding, jam, fruit filling, flavoring, sweetener, jelly, yeast puree, salad, seasoning, pastry, etc.

Pill paste, extract, emulsion, ointment, etc.

Hotels, sports grounds, exhibition halls, railway stations, ship terminals, groundwater discharge, etc.

Special tank truck, vacuum sewage truck, etc.

Clay, lime slurry, colored glaze, iron oxide mud, etc.