Online Lobe Pump Vacuum Discharge System

|

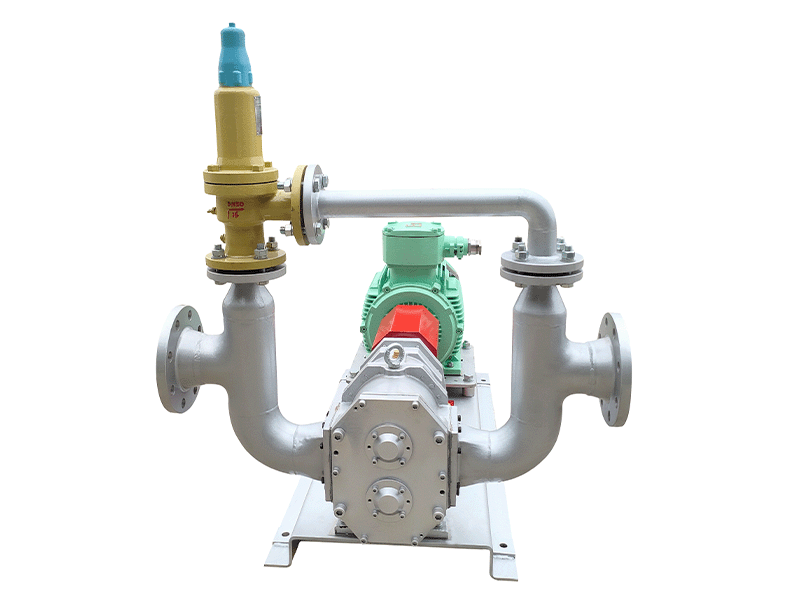

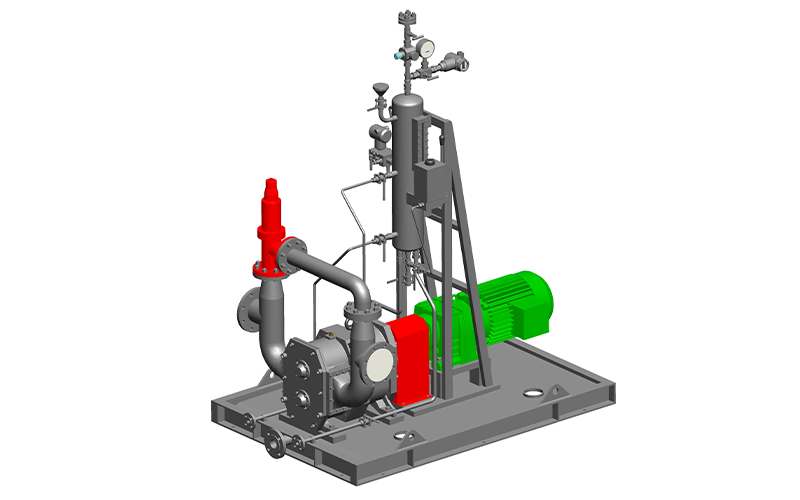

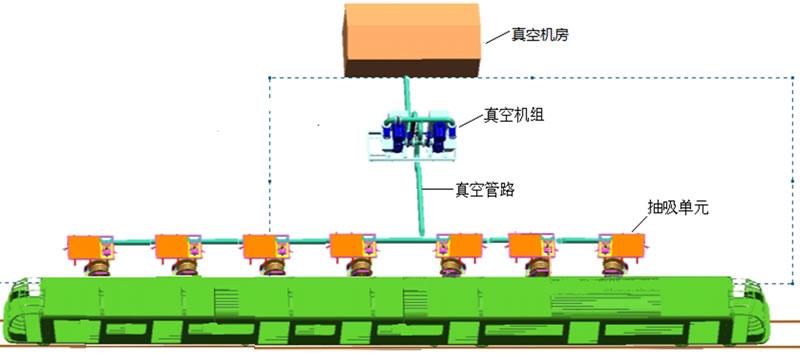

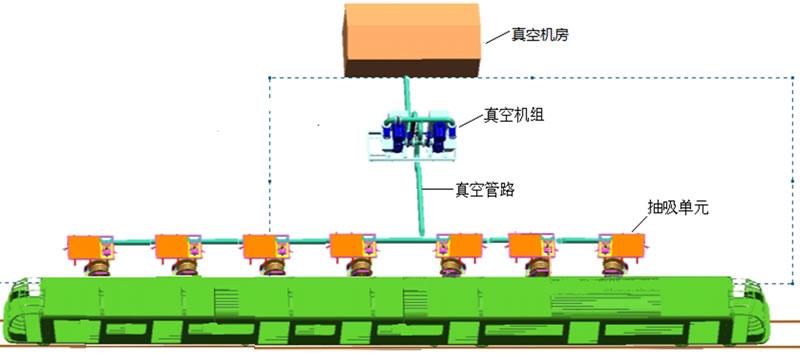

The online lobe pump vacuum discharge system consists of three parts: an online rotary lobe pump vacuum unit, a vacuum pipeline, and a vacuum discharge unit. Its working principle is to use the online rotary lobe pump unit to evacuate the vacuum pipeline to a vacuum, and use the toilet waste box to The pressure difference between the atmospheric pressure in the dirt tank and the waste discharge pipeline will suck the waste into the pipeline and send it to the vacuum center, and then discharge it to the treatment facility.

- Vacuum unit: generates vacuum and maintains system vacuum, discharges dirt, indicates and automatically controls;

- Vacuum pipeline: connects the vacuum unit and the vacuum discharge unit, maintains a closed state, and transports and discharges waste;

- Vacuum waste removal unit: Connected to the toilet waste box to suck toilet waste into the vacuum pipeline.

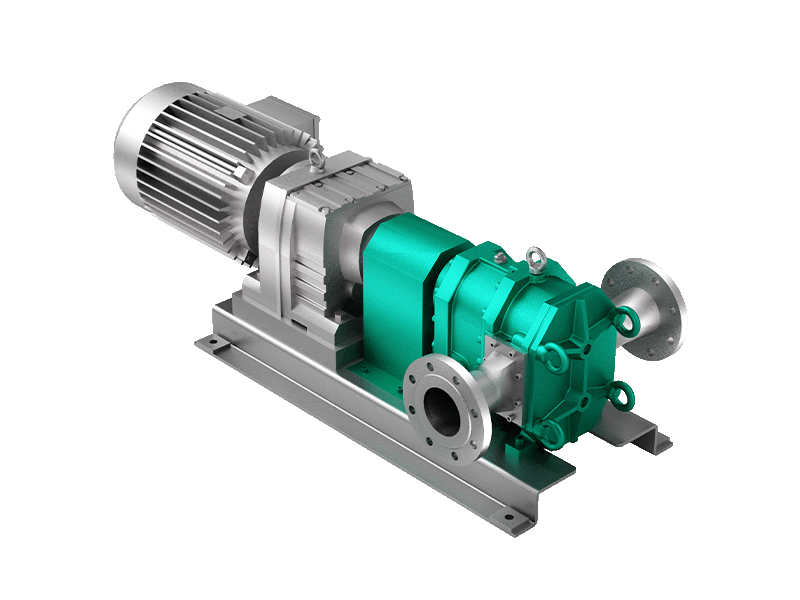

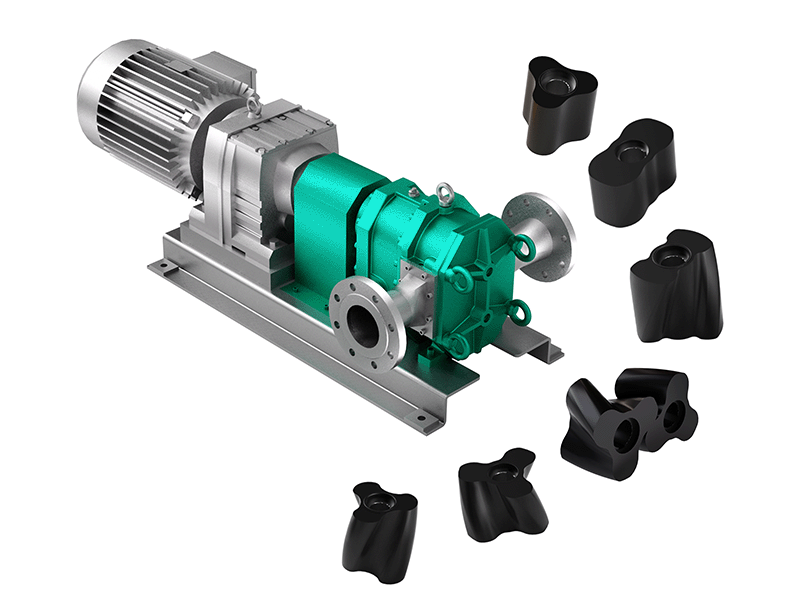

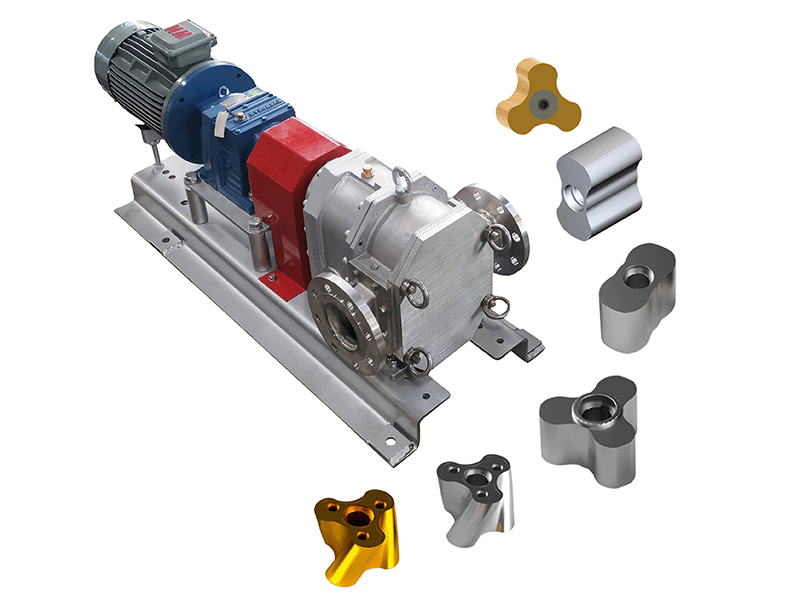

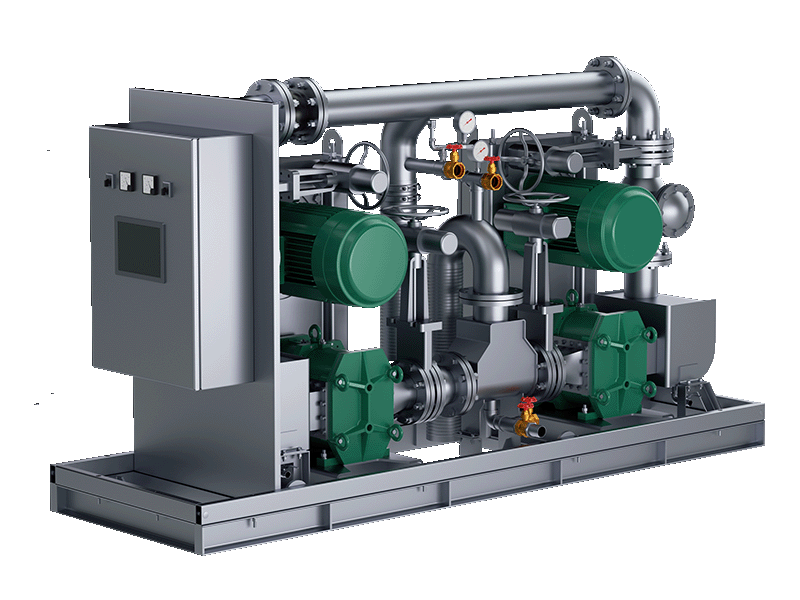

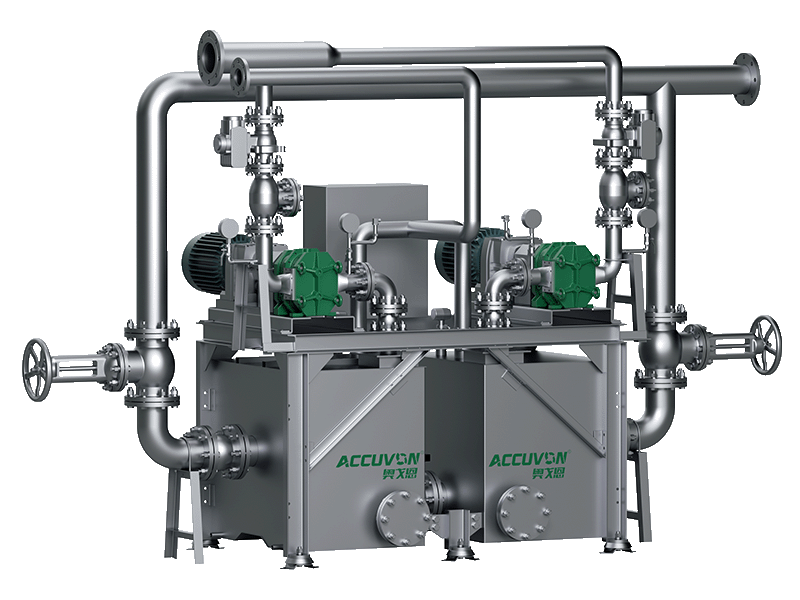

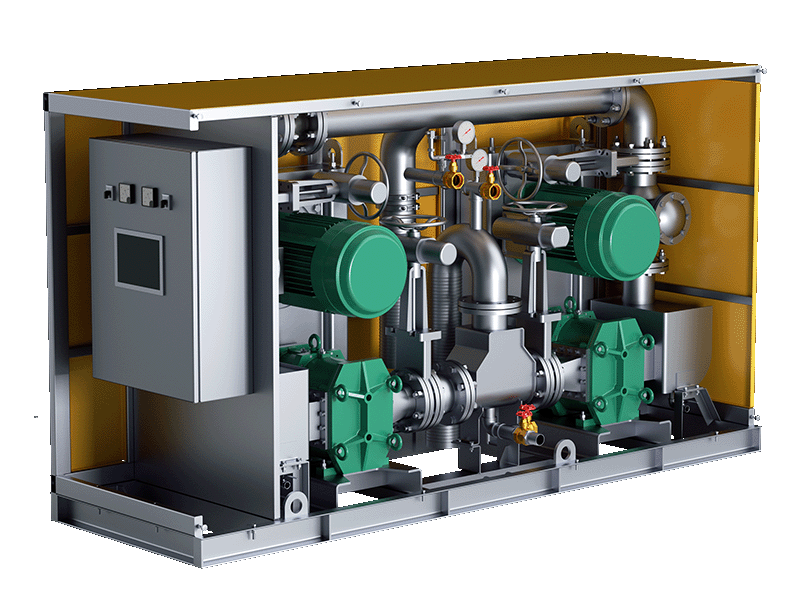

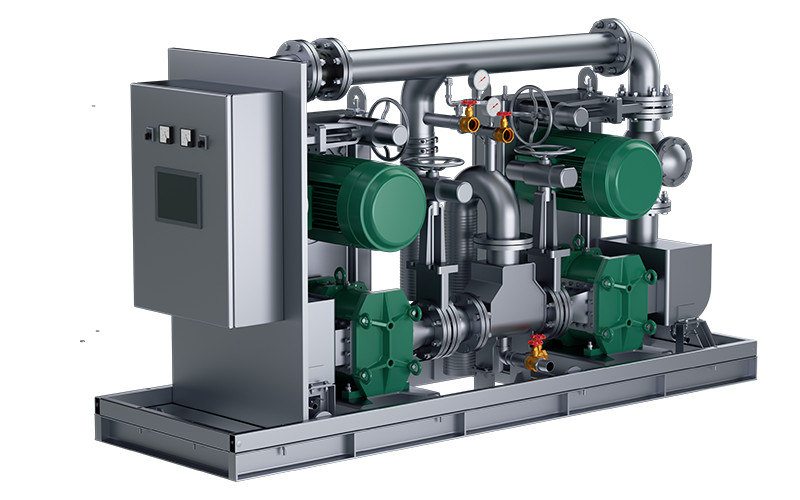

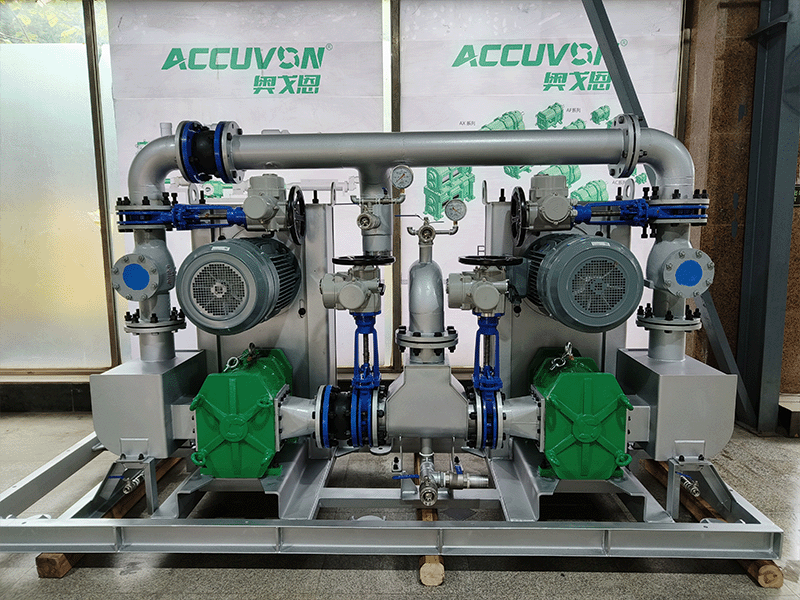

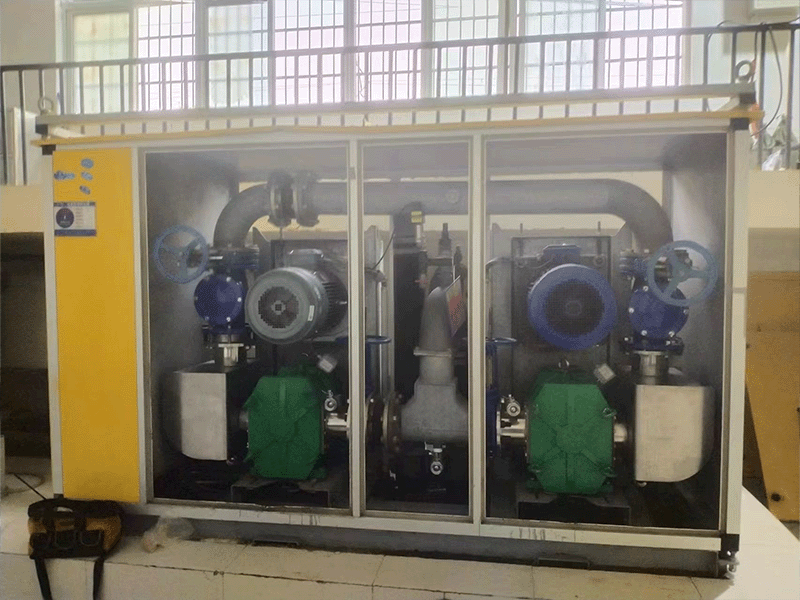

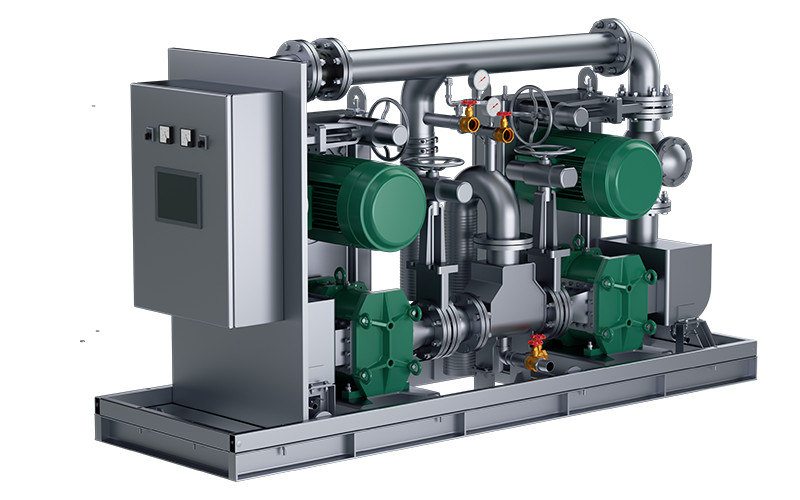

ACCUVON's vacuum sewage unloading equipment adopts an online operation form and uses an online vacuum unit. The sewage does not need to be equipped with a separate sewage pump and sewage storage tank, and can be directly sucked and discharged by the online unit. Meet the advanced technical requirements for environmental protection and energy-saving equipment. The vacuum unit is a complete set of equipment consisting of two rotary lobe pumps, modular and integrated assembly. When one lobe pump fails, the system can automatically start and convert the other device to continue working normally and meet the system's need to form a normal vacuum. The equipment adopts on-site PLC control and is equipped with automatic pressure monitoring, automatic control, fault display and alarm functions. The system automatically controls the operation of the equipment to generate vacuum and discharge waste without personnel on duty. It is equipped with manual/automatic control and can be switched.

Basic performance of online rotary lobe pump vacuum sewage discharge system:

|

The online lobe pump vacuum sewage discharge system adopts online operation mode. The system vacuum degree is maintained between -30kPa and -70kPa, which can realize continuous operation from the suction surface to the pressure surface. The sewage is directly sucked and discharged by the unit under the action of pressure difference. Discharge without the need for additional sewage pumps and sewage storage tanks.

All parts of the vacuum unit, vacuum discharge unit and vacuum pipeline are completely sealed without odor, blockage, air leakage, oil leakage, water leakage or dirt leakage, meeting the requirements of advanced technology for environmental protection and energy-saving equipment.

The online lobe pump vacuum sewage unloading system can meet the suction, flushing and discharge needs of the sewage tanks of 8 or 16 CRH EMU trains and general-speed passenger cars.

Dirt removal ability:

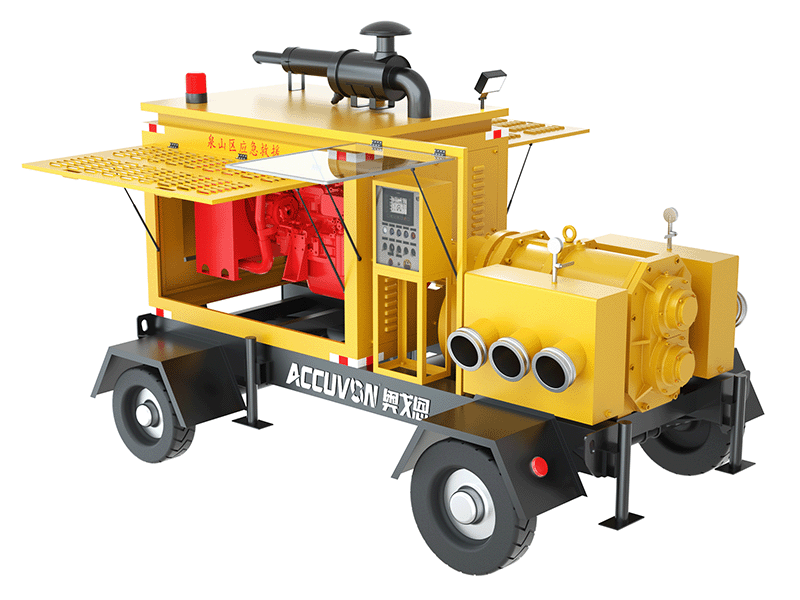

In order to meet the pollution unloading needs of different places (motor trains/motor trains/passenger trains/stations) and different types of trains (EMU trains/normal speed passenger cars), our company has developed the online with different pollution unloading capabilities. Lobe pump vacuum sewage discharge system and enhanced online lobe pump vacuum sewage discharge system.

online lobe pump vacuum sewage unloading system: can meet the sewage unloading operation of 4 sewage unloading units at the same time. The emptying time of a single 600-liter sewage tank does not exceed 3 minutes. The sewage unloading operation time of an 8-car EMU train is The unloading operation time of a 16-car EMU train is less than 12 minutes and less than 24 minutes.

enhanced online lobe pump vacuum sewage unloading system: When long-distance buses are parked and the preparation time is short, 4-6 sewage unloading units can be unloaded at the same time, and a single 600 liters of sewage can be discharged. The emptying time of the storage bin shall not exceed 4 minutes.

Performance Parameter Table

|

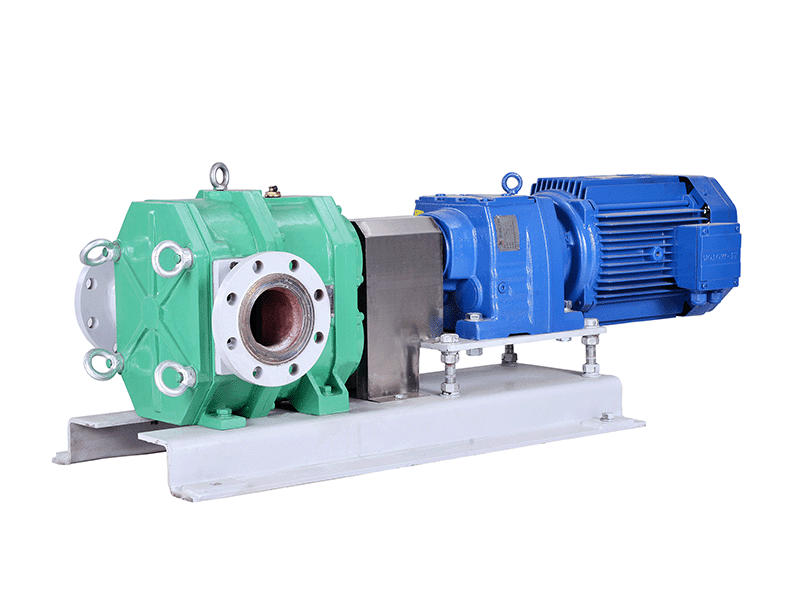

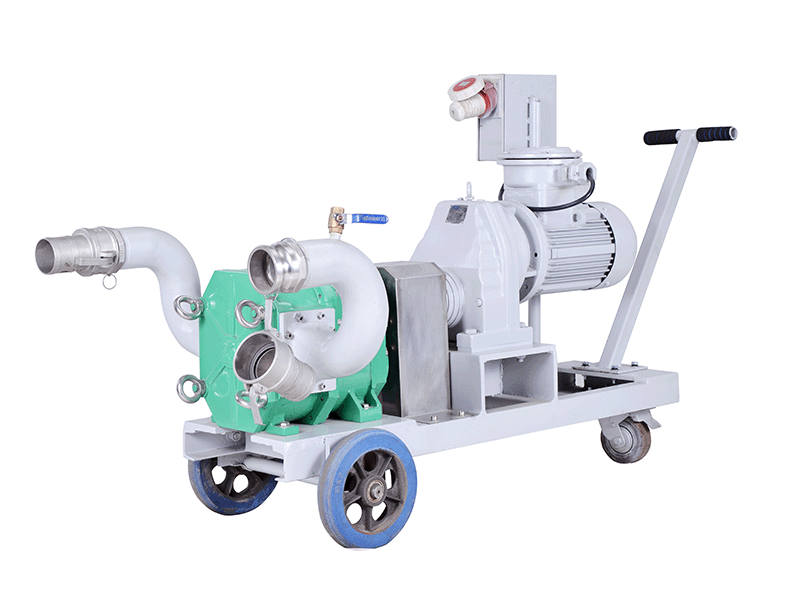

Online Double Pump Lobe Pump Unit

|

| Specifications And Models |

AP100-105Q/7.5 kw |

AP120-140Q /11 kw |

AP140-210Q /15 kw |

| Reference Model |

VX136-105Q/7.5 kw |

VX136-140Q /11 kw |

VX136-210Q /15 kw |

| Pump Quantity |

2 set |

2 set |

2 set |

| Suction Capacity |

2x 60 m³/h |

2x 80 m³/h |

2x 110 m²/h |

| System Vacuum Degree (Adjustable) |

0-0.6 bar (normal) |

0-0.6 bar (normal) |

0-0.6 bar (normal) |

| Maximum Discharge Pressure |

2bar |

2.5bar |

3bar |

| Power Consumption (Single Pump Operation When δP=0.6 Bar) |

4.2 kw |

5.4 kw |

6.3kw |

| Control Cabinet |

PLC Automatic Control System |

PLC Automatic Control System |

PLC Automatic Control System |

| Voltage |

380V,50Hz,3P |

380V,50Hz,3P |

380V,50Hz,3P |

| Connector Entry |

DN100 |

DN100 |

DN150 |

| Connector Outlet |

DN100 |

DN100 |

DN150 |

| Common Floor |

Galvanized steel |

Galvanized steel |

Galvanized steel |

Overall Dimensions Of The Unit

(Length X Width X Height), Approx. |

3000 x 1100 x 2000 mm |

3000 x 1100 x 2000 mm |

3000 x 1100 x 2000 mm |

| Weight Approx. |

1650 kg |

1950 kg |

2100 kg |

| Environment |

+5 to +40 °C |

+5 to +40 °C |

+5 to +40 °C |

| Environmental Conditions |

indoor, medium |

indoor, medium |

indoor, medium |

| System Vacuum Recovery Time |

≤3min |

≤3min |

≤3min |

Online Double Pump Lobe Pump Unit

|

| Specifications And Models |

AF150-184Q /22 kw |

AF200-260Q /30 kw |

AX300-500Q /37 kw |

| Reference Model |

VX186-184Q /22 kw |

VX186-260Q /30 kw |

EL1550 |

| Pump Quantity |

2 set |

2 set |

2 set |

| Suction Capacity |

2x 160 m³/h |

2x 300 m³/h |

2x 500 m³/h |

| System Vacuum Degree (Adjustable) |

0-0.6 bar (normal) |

0-0.6 bar (normal) |

0-0.6 bar (normal) |

| Maximum Discharge Pressure |

3bar |

2bar |

2bar |

| Power Consumption (Single Pump Operation When δP=0.6 Bar) |

9.6kw |

17.4kw |

21kw |

| Control Cabinet |

PLC Automatic Control System |

PLC Automatic Control System |

PLC Automatic Control System |

| Voltage |

380V,50Hz,3P |

380V,50Hz,3P |

380V,50Hz,3P |

| Connector Entry |

DN150 |

DN200 |

DN200 |

| Connector Outlet |

DN150 |

DN200 |

DN200 |

| Common Floor |

Galvanized steel |

Galvanized steel |

Galvanized steel |

Overall Dimensions Of The Unit

(Length X Width X Height), Approx. |

3000 x 1100 x 2000 mm |

3150x1100x2000 |

3150x1100x2000 |

| Weight Approx. |

2510 kg |

3100 kg |

4500 kg |

| Environment |

+5 to +40 °C |

+5 to +40 °C |

+5 to +40 °C |

| Environmental Conditions |

indoor, medium |

indoor, medium |

indoor, medium |

| System Vacuum Recovery Time |

≤3min |

≤3min |

≤3min |