Accuvon Synthetic Rubber Material Rotor Description

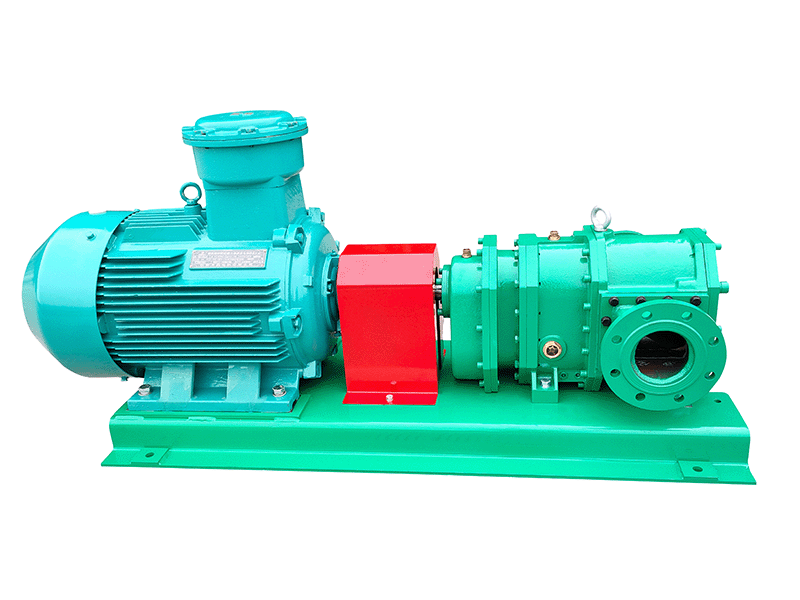

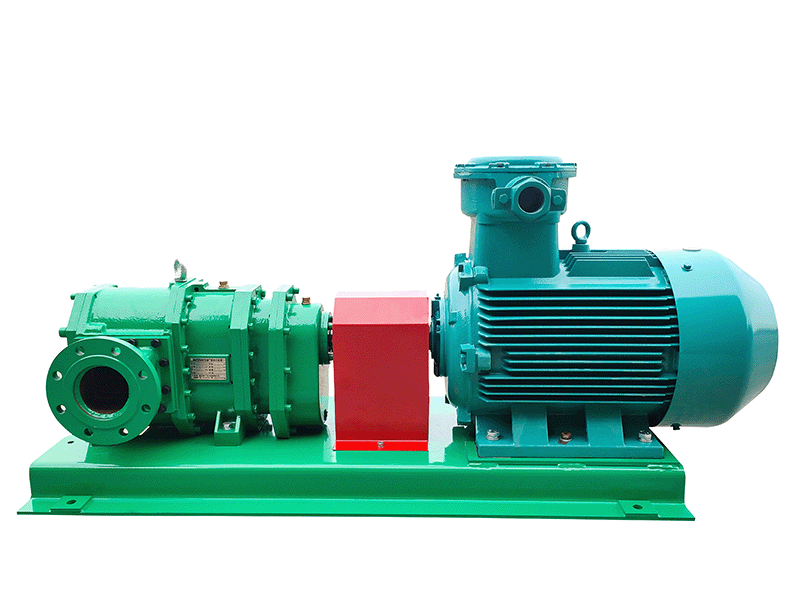

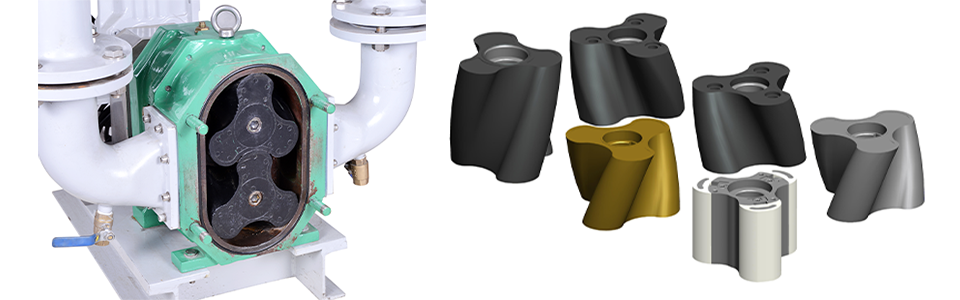

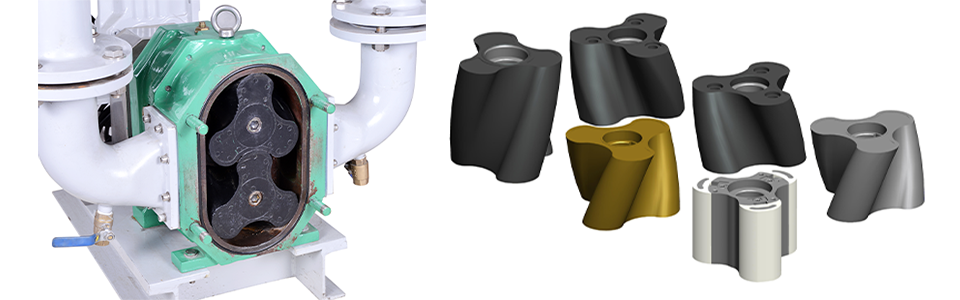

ACCUVON can provide rotors in rubber, plastic and stainless steel materials. This section will focus on rubber and plastic rotor pumps. ACCUVON is the world's largest manufacturer of elastomer-coated lobe pumps. Our elastomeric rotors are diversified to meet the individual needs of various users around the world.

- NBR: nitrile rubber, heat resistance 80℃, suitable for transporting media such as dirt deposits, gasoline, grease, diesel fuel, and floc. Its special properties are oil resistance and good wear resistance;

- FKM: fluorine rubber, heat resistance 150℃, suitable for transporting medium: dissolved salt water, various oils, acids, alkali, special properties are good oil resistance, acid and alkali resistance;

- EPDM: EPDM rubber, heat resistance 130°C, suitable for transporting media such as water, liquid fertilizer, sewage deposits, biogas substrate, special attribute is good water resistance;

- SBR: natural rubber, heat resistance 60℃, suitable for transporting liquid fertilizer, special properties are good wear resistance and anti-aging;

- HNBR: Hydrogenated nitrile butadiene rubber, with heat resistance of 150°C and cold resistance of -55~-38°C. The media suitable for transportation are fuel oil, lubricating oil, and aromatic solvents. Its special properties are good oil resistance and ozone resistance;

- PTFE: Polytetrafluoroethylene, heat resistance 230°C, suitable for transporting various high-volume, highly corrosive chemical media, especially good solvent resistance;

- PUR: Polyurethane, heat resistance 50℃, suitable for transporting abrasive particle media, special attribute is good wear resistance;

- CSM: Polyethylene synthetic rubber, heat resistance 80°C, suitable for transporting abrasive particle media, special attributes are good wear resistance, good acid resistance, and good alkali resistance;

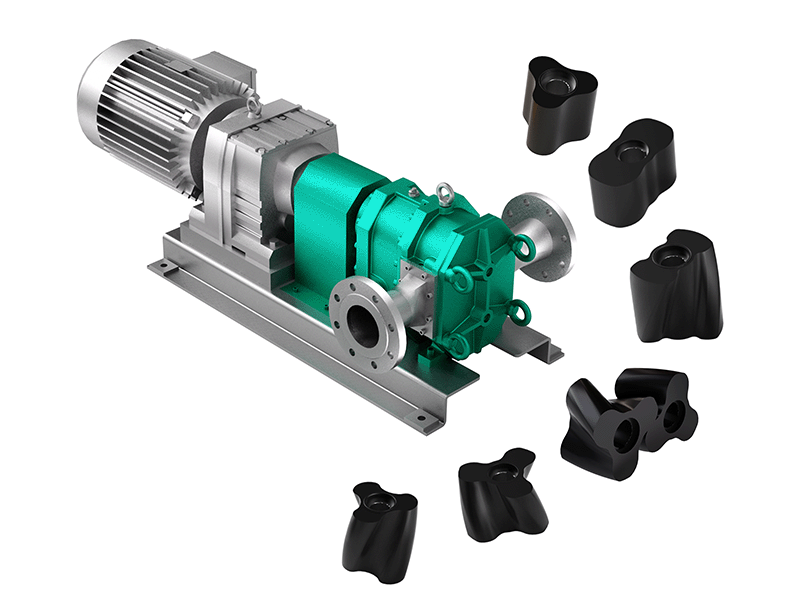

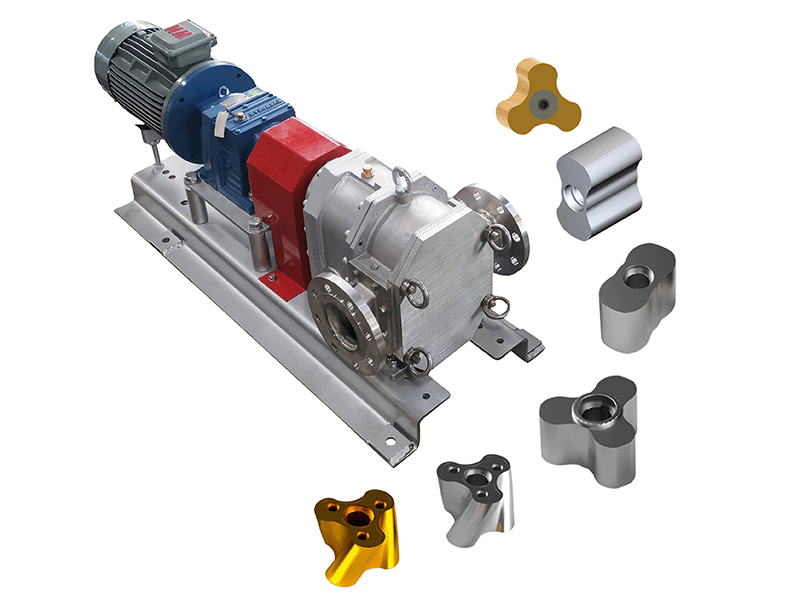

Overview of various rubber or plastic rotors

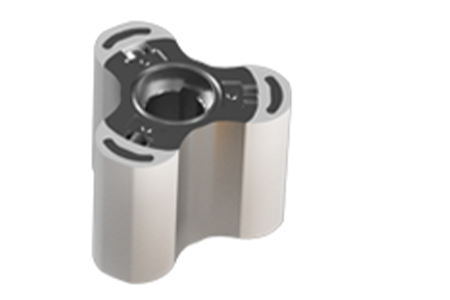

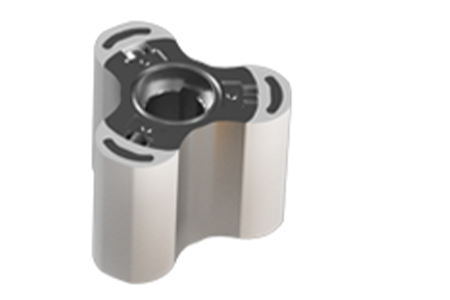

Tri-lobe, screw profile Wide border optimum rubber rotor

- 1、entirely elastomer coated

- 2、with non-wetted core

- 3、with low pulsation

- 4、high volumetric efficienc

Tri-lobe, linear, with replaceable rotor tips PTFE rotor

1、replaceable PTFE or plastic inlaid rotor tips

2、for chemically problematic fluids

3、solvents-resistant

4、high volumetric efficiency

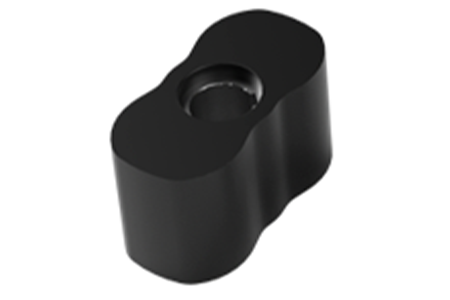

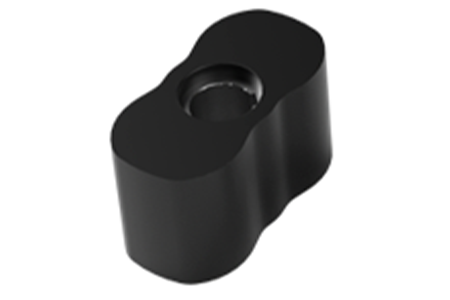

Dual-lobe, screw profile Wide border optimum rubber rotor

1、large sealing area with effective scraping edge

2、for abrasive and aggressive fluids

3、almost pulsation-free and high pressure stability

Dual-lobe, linear optimum rubber rotor

1、entirely elastomer coated

2、for aggressive and abrasive fluids

3、good pass performance

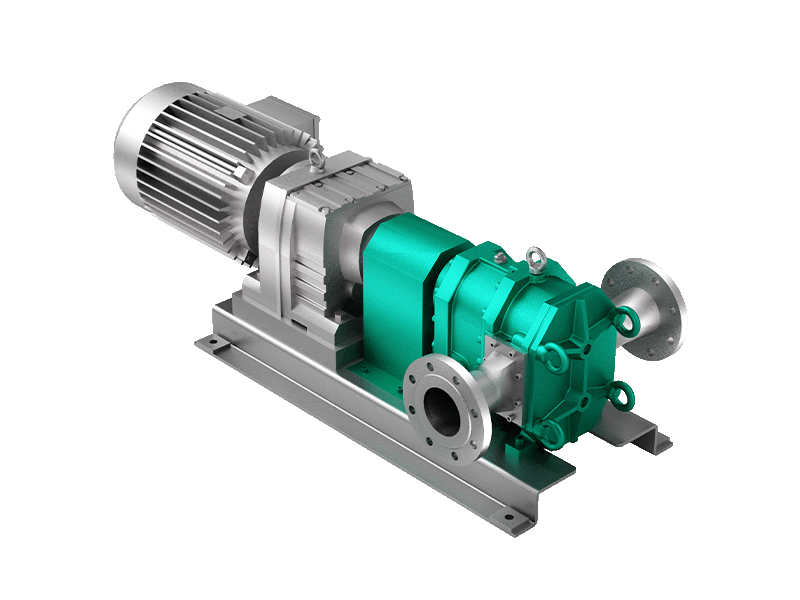

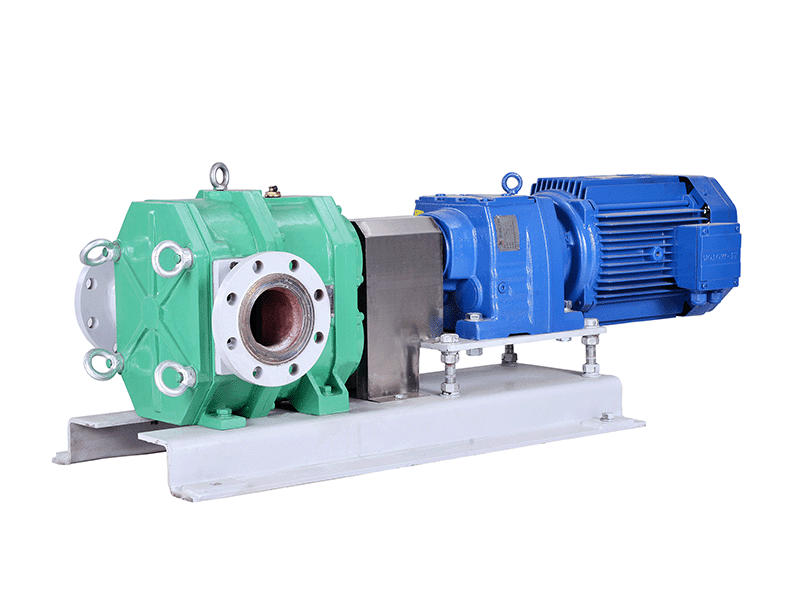

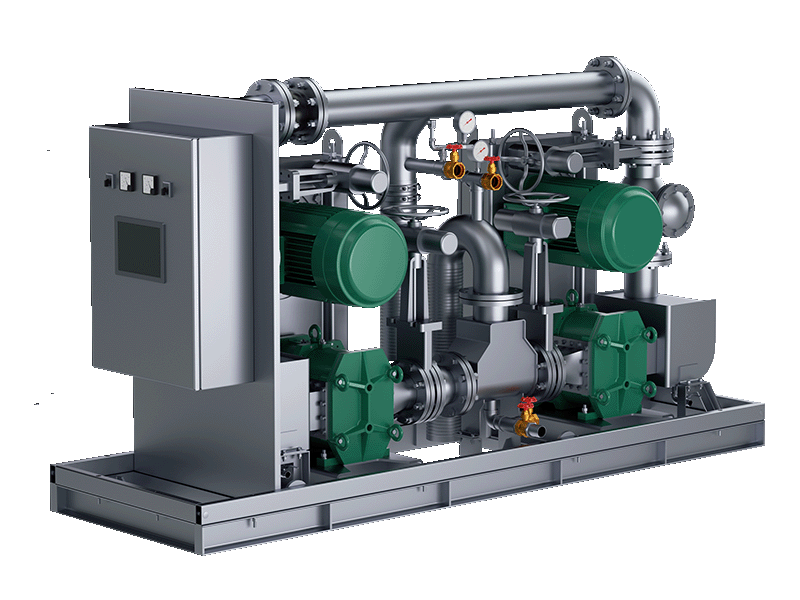

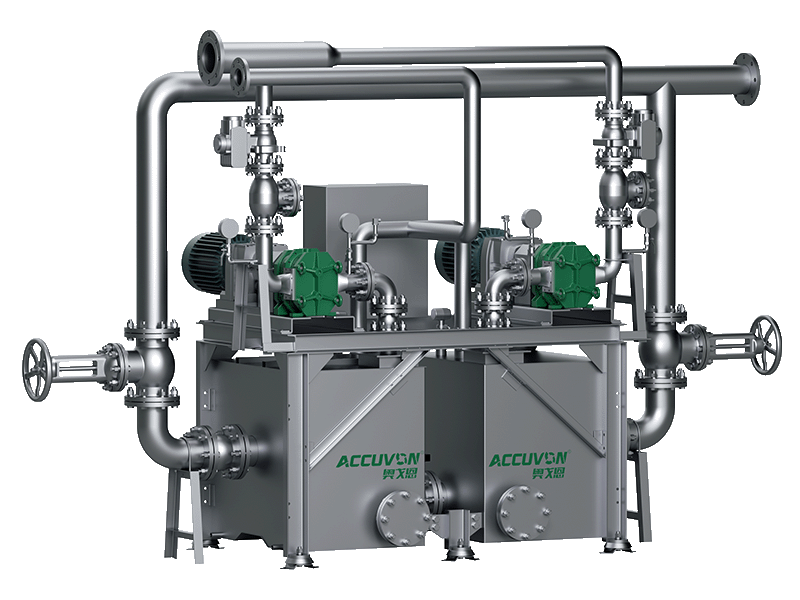

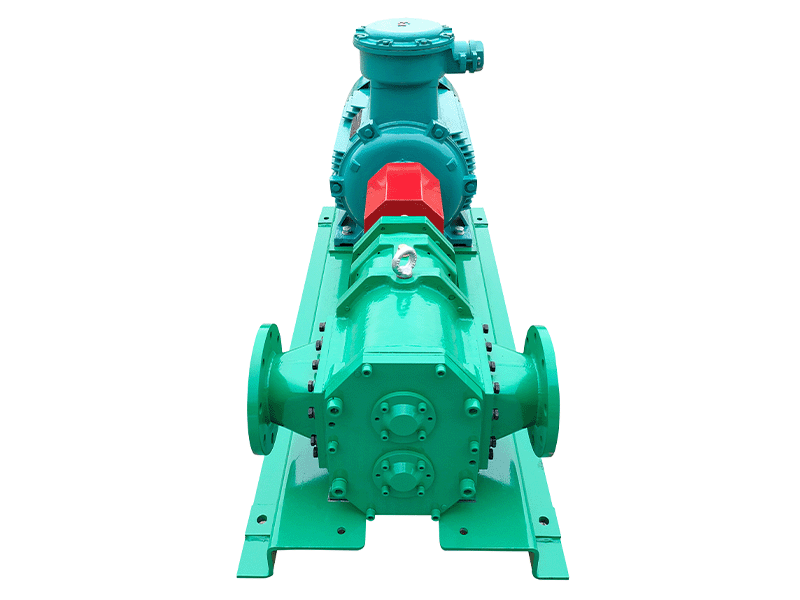

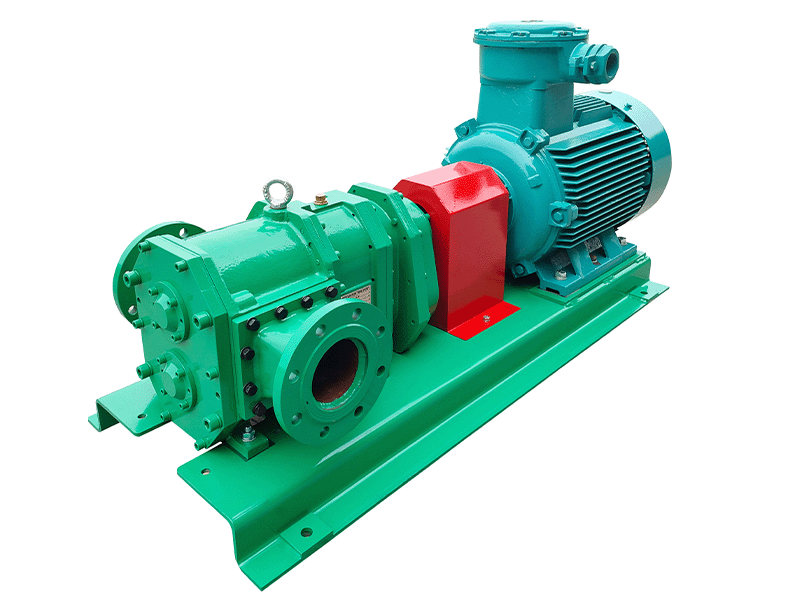

- + 14 pump sizes with flow rates of up to 3,200 m³/h

- + Pressure resistant up to 25 bar

- + API-676-compliant design

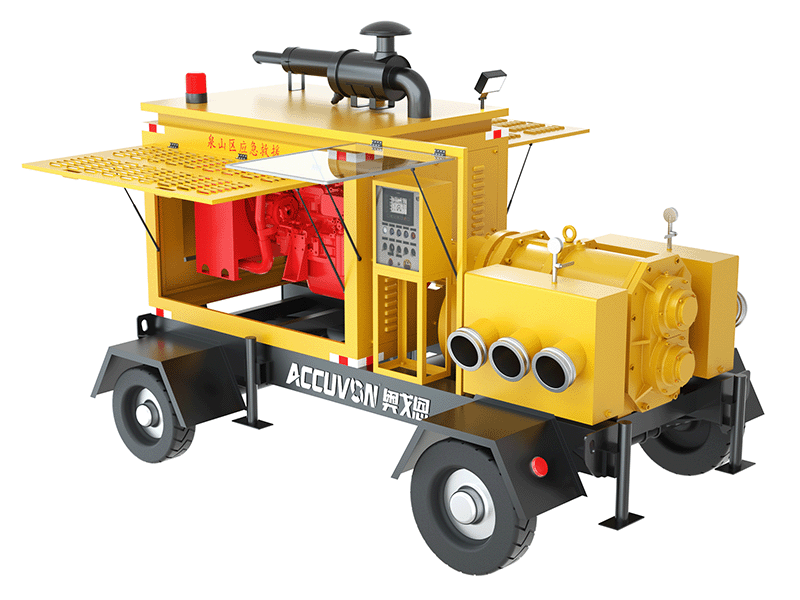

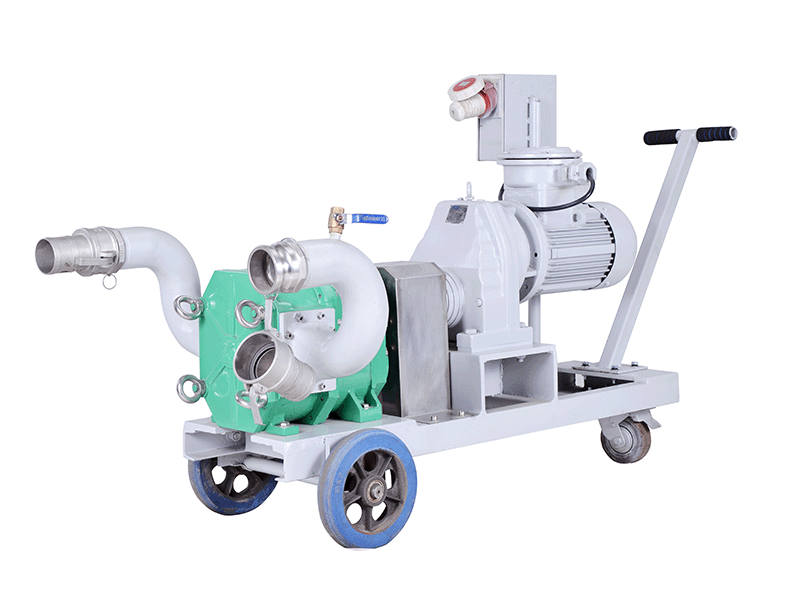

- + Self-priming, pumping in slurp operation(或Self-priming up to 9 m liquid column)

- + Resistant to solids

- + Flow rate adapted to the speed

- + Gentle pumping of shear-sensitive media

- + Almost pulsation-free pumping

- + Short-term dry-run capability

- + Reversible pumping

- + Ease of maintenance

- + Compact, space saving design

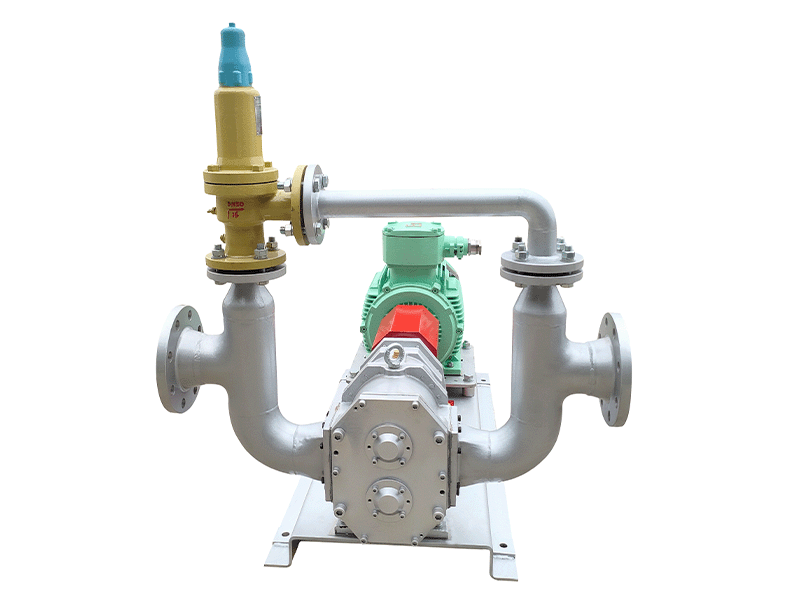

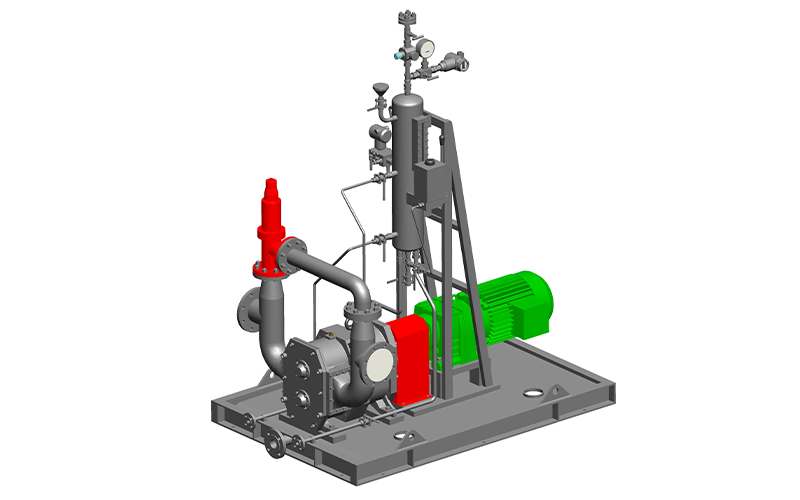

Main application areas of rubber lobe pumps

sewage treatment, chemical wastewater, sludge dewatering machine feeding, sewage pumping station, scum, lime slurry, landfill leachate, membrane treatment, MBR application, water supply and sedimentation tank sludge, etc.

crude oil, gasoline, diesel, lubricating oil, heavy oil, residual oil.

titanium dioxide, gypsum, materials with impurities.

bilge wastewater, domestic sewage, waste oil, sludge, fuel oil.

Vacuum discharge systems.

special tank trucks, vacuum sewage trucks.

clay, lime slurry, colored glaze, iron oxide mud.

food waste, expired food, animal manure, various organic matter, etc.