Lobe pump type closed sewage lifting device (pumping station system) selection reference tableModel Description:

- For example: MB-AP80-450-1 or MB-AP80-450-2

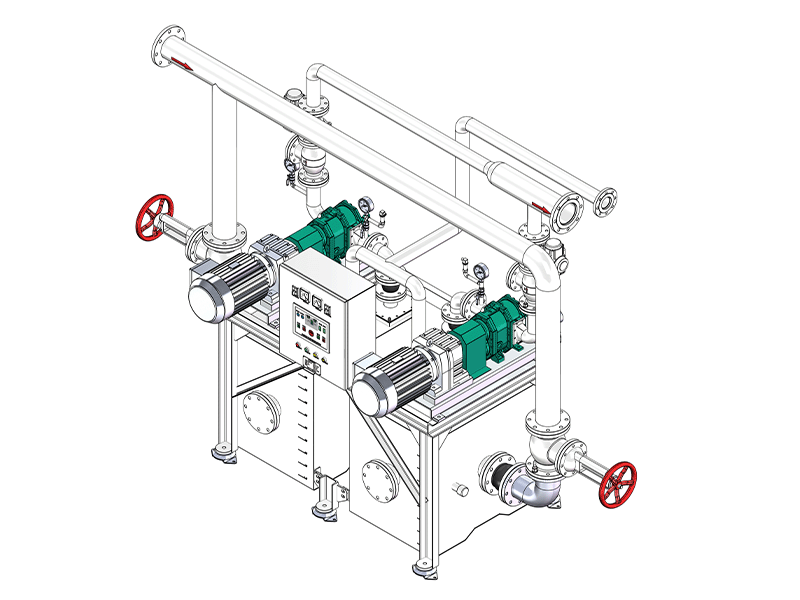

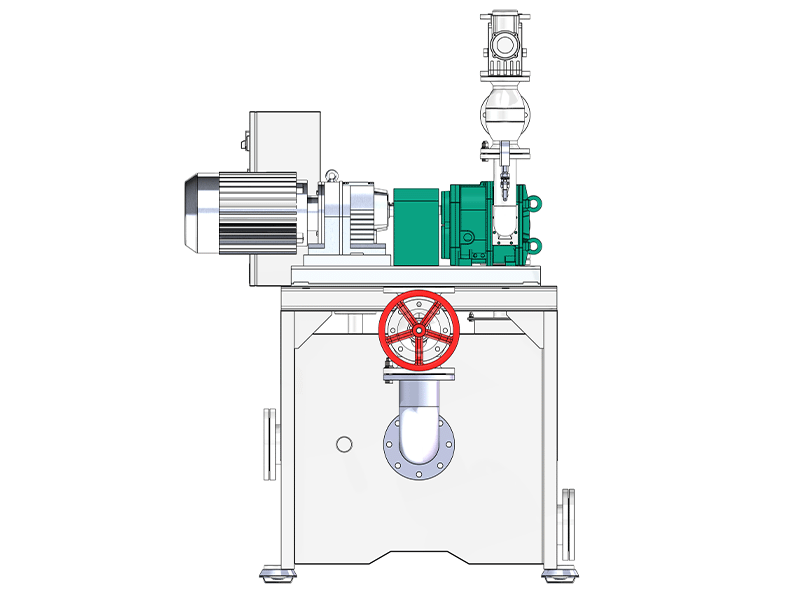

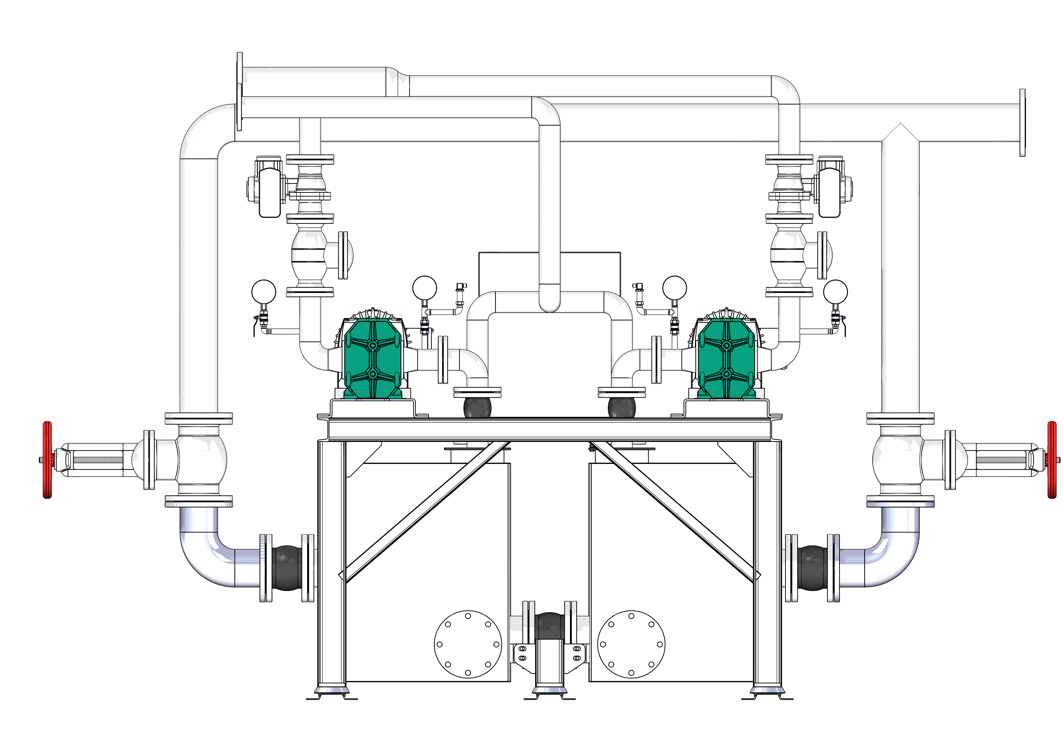

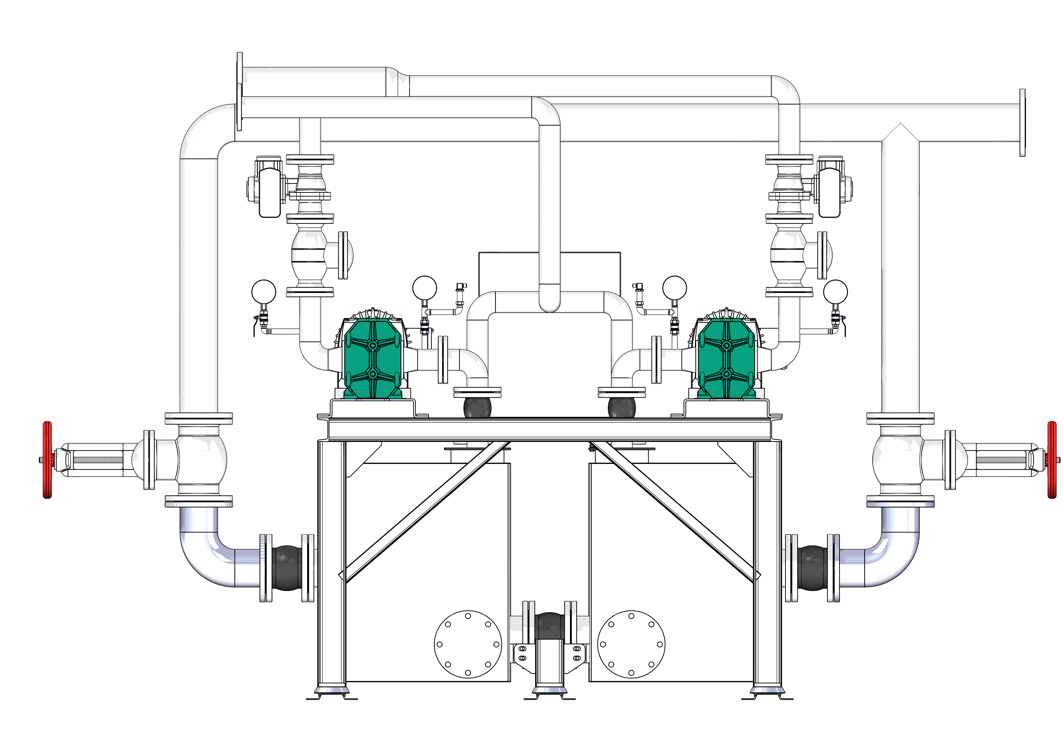

- MB: Lobe pump type closed sewage lifting device (pumping station system)

- AP80: Indicates the model of the lobe pump, standard diameter DN80 (optional diameter DN65)

- 450: Indicates the water tank volume is 450L

- 1: Indicates a single water tank

- 2: Indicates double water tanks

| No |

Model |

Flow m³/h |

Lift m |

volume L |

Single/double water tank |

| 1 |

MB-AP80-450-1 |

20 |

15-120 |

450 |

single |

| 2 |

MB-AP80-750-1 |

20 |

20-120 |

750 |

single |

| 3 |

MB-AH80-900-1 |

20 |

25-120 |

900 |

single |

| 4 |

MB-AP100-450-1 |

30 |

20-120 |

450 |

single |

| 5 |

MB-AP100-750-1 |

30 |

25-120 |

750 |

single |

| 6 |

MB-AP100-900-1 |

30 |

30-120 |

900 |

single |

| 7 |

MB-AH80-450-2 |

20 |

15-120 |

900 |

double |

| 8 |

MB-AP80-600-2 |

20 |

15-120 |

1200 |

double |

| 9 |

MB-AH80-750-2 |

20 |

25-120 |

1500 |

double |

| 10 |

MB-AP100-450-2 |

30 |

20-120 |

900 |

double |

| 11 |

MB-AP100-600-2 |

30 |

25-120 |

1200 |

double |

| 12 |

MB-AP100-750-2 |

30 |

30-120 |

1500 |

double |

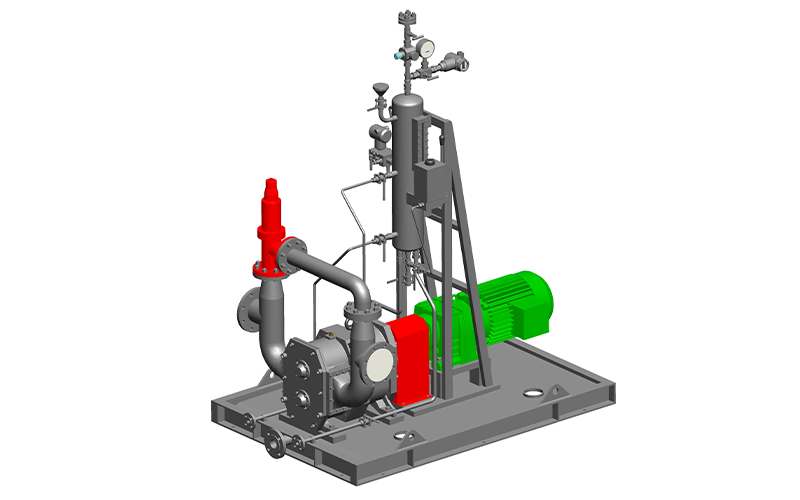

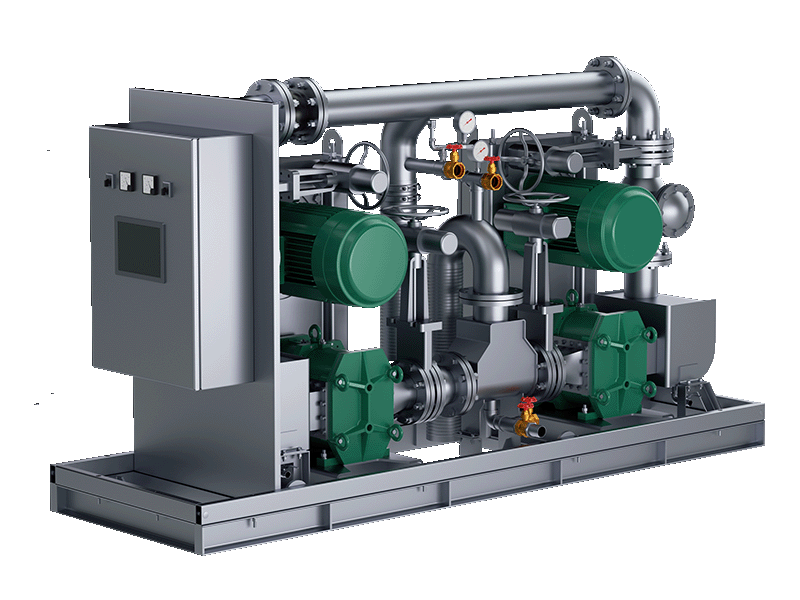

Comprehensive advantages of lobe pump type closed lifting device (pumping station system):

- 1. Designed specifically for commercial buildings and underground bathrooms

- 2. Comfort control

- 3. Sensitive liquid level sensor

- 4. Larger volume

- 5. Flexible horizontal connection

- 6. Airtight, watertight and pressure-bearing

- 7. Less precipitation

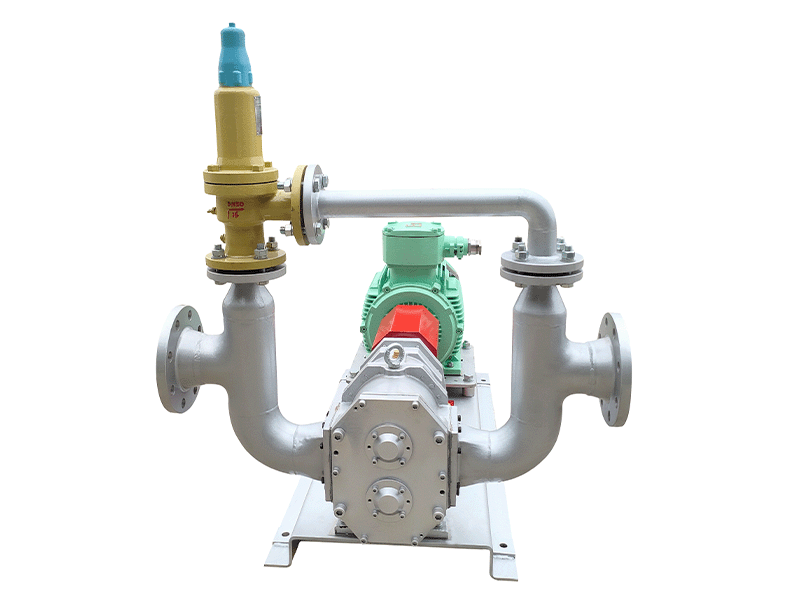

- 1. The system has a simple principle, is easy to learn and use, and does not require high design and installation requirements;

- 2. Good airtightness. The airtight water tank is made of integral injection molding, leaving only the pipe joints and inspection openings to ensure airtightness;

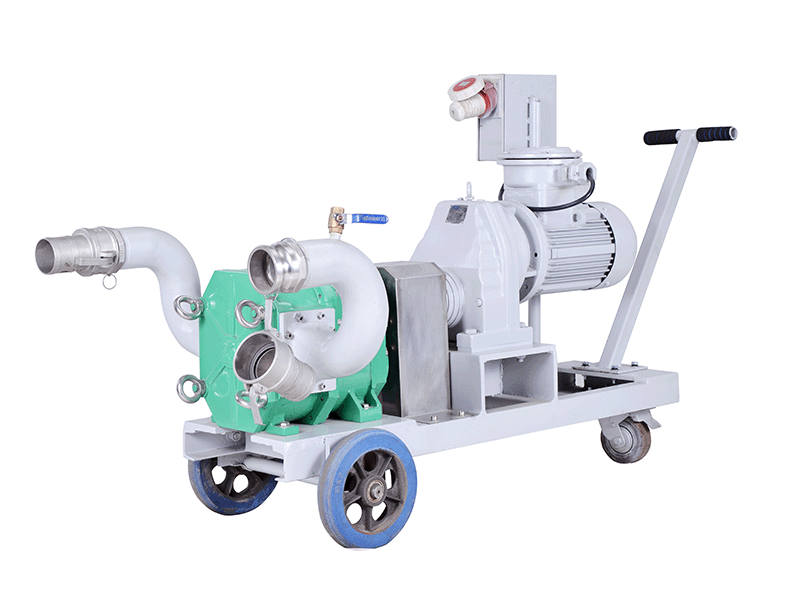

- 3. Simple maintenance. The lobe pump type closed sewage lifting pump station is small in size and can be operated directly next to the equipment. It no longer needs to enter the water collection well with harsh working environment, avoiding potential dangers and providing a relatively comfortable job for repair and maintenance personnel. space;

- 4. Avoid pollution. Even in extreme situations such as fire extinguishing and rainstorms, if the drainage in the basement is not smooth and the accumulated water floods the integrated sewage equipment, the sewage in the equipment will not leak, causing pollution to the surrounding environment;

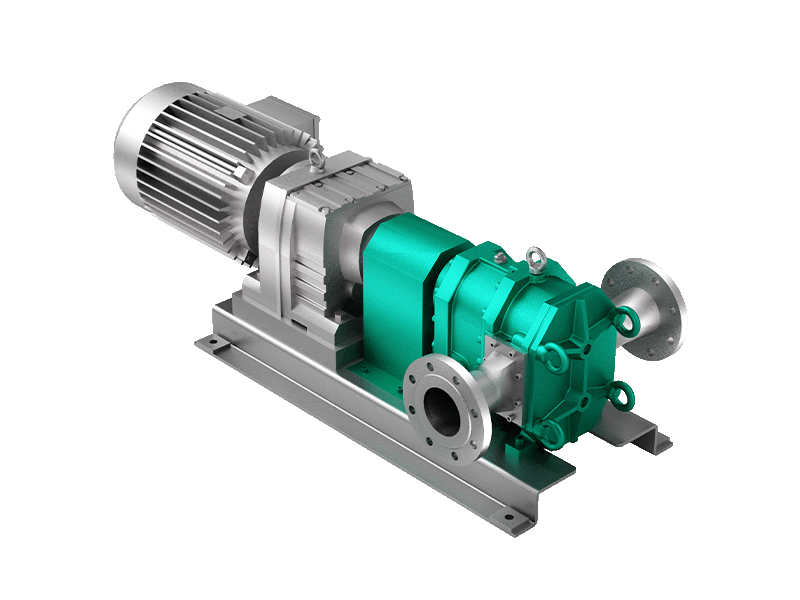

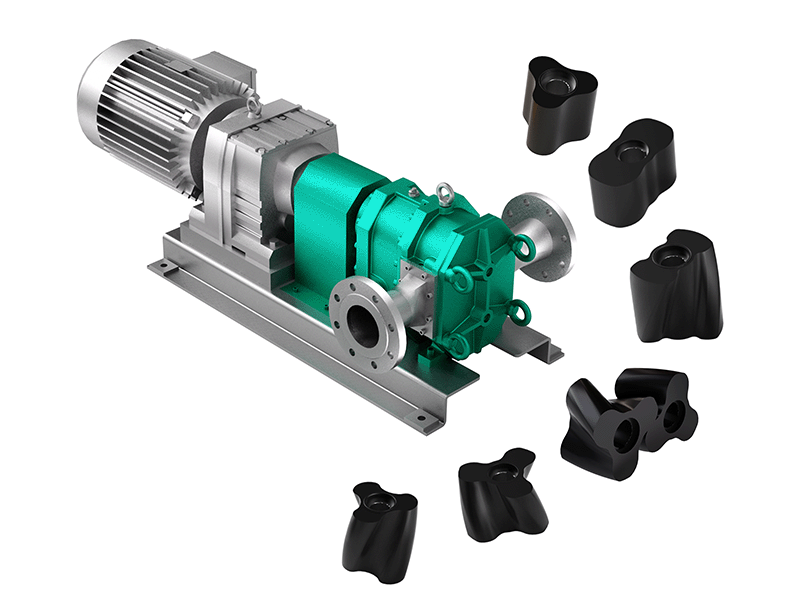

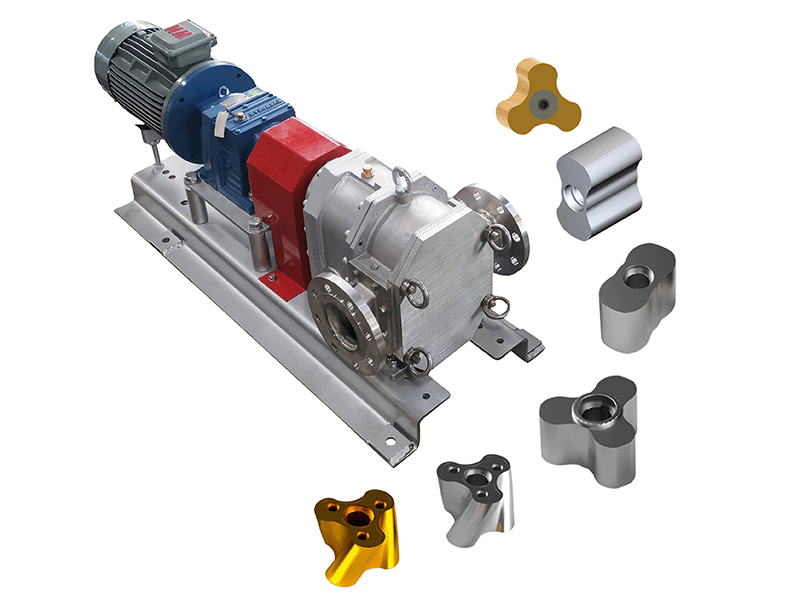

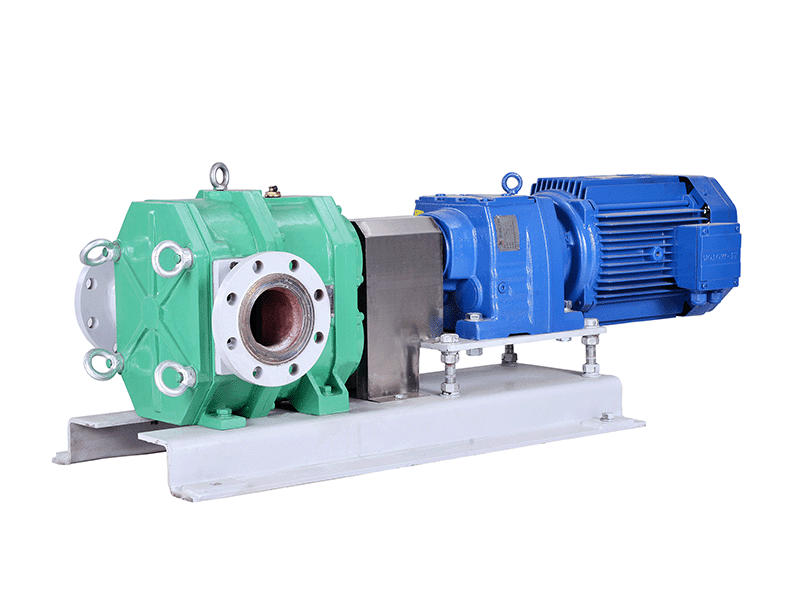

◆ High lift and strong self-priming force

- ◆ Dual-axis design, no shaft jamming phenomenon

- ◆Media can enter and exit in both directions, no forward or reverse direction

- ◆ Large diameter with shearing function

- ◆ Can transport gas, liquid and solid three-phase mixed media

- ◆ Equipped with sweep function

- ◆ Using electrode sensors and pneumatic sensors as backups for each other, the safety factor is higher

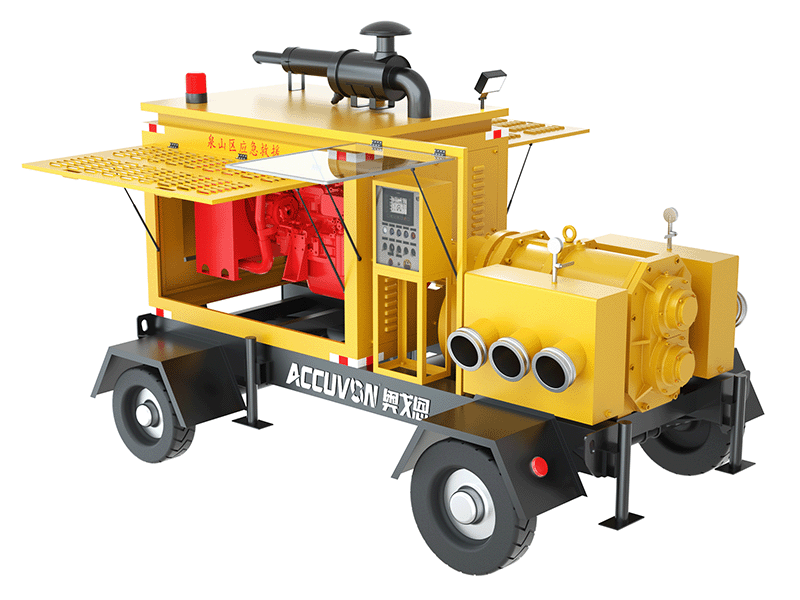

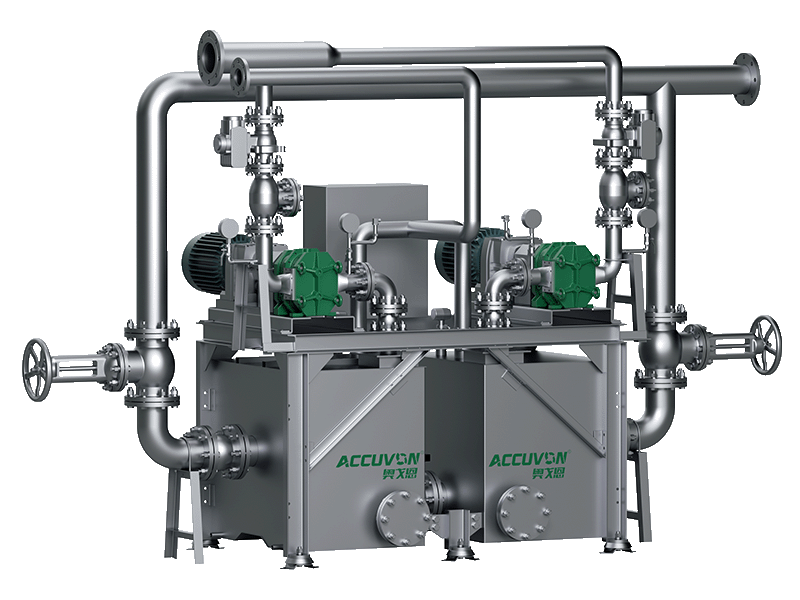

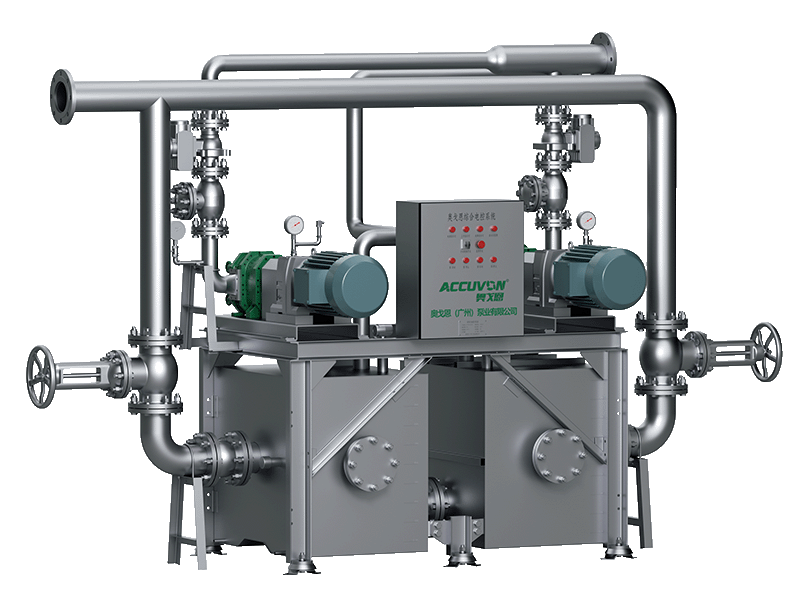

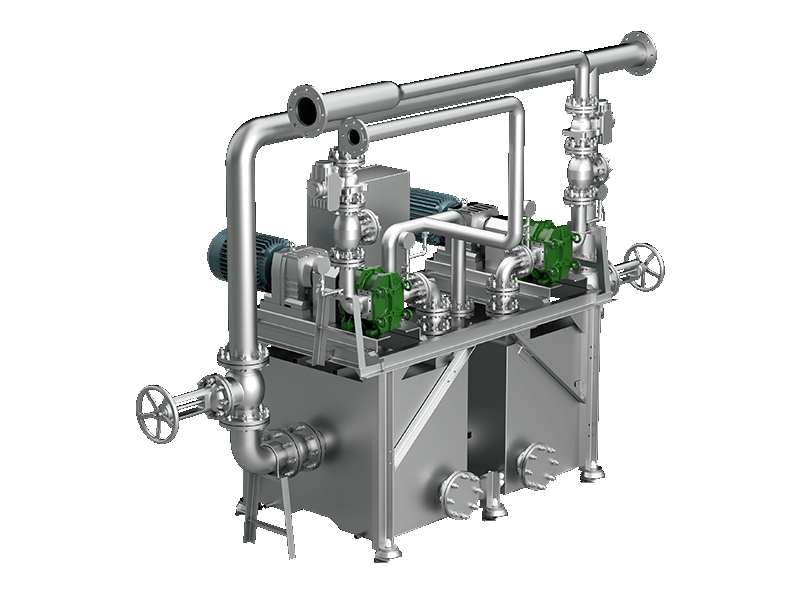

1. Mainly used for underground sewage collection and enhanced discharge in underground rail transit, underground shopping malls, commercial areas, large swimming pools, water parks, underground shower rooms and other large venues and large buildings;

2. Municipal wastewater, domestic sewage, and industrial wastewater are suitable for situations where the pump room structure is long and narrow and the pump room is not high;