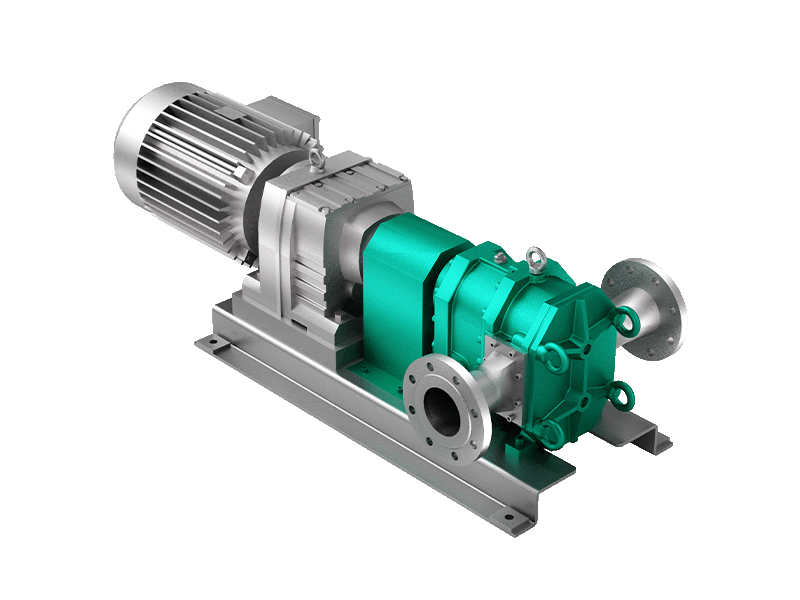

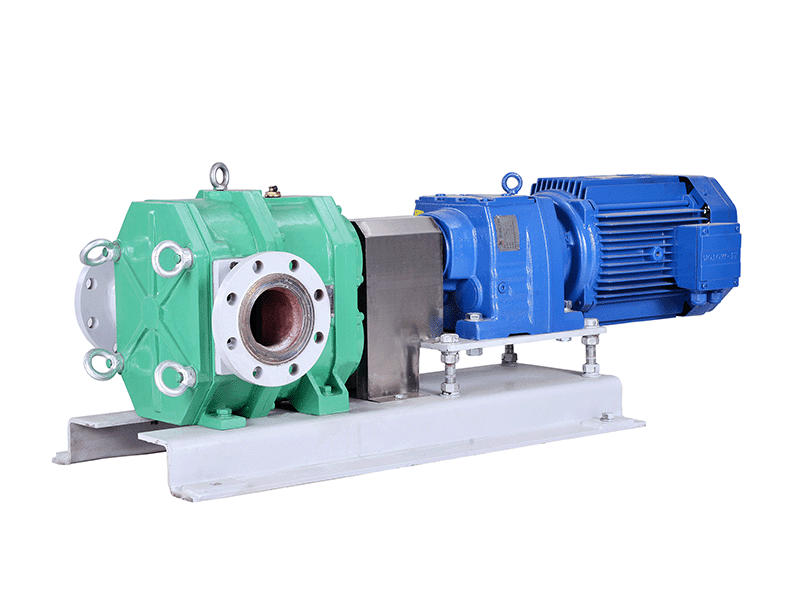

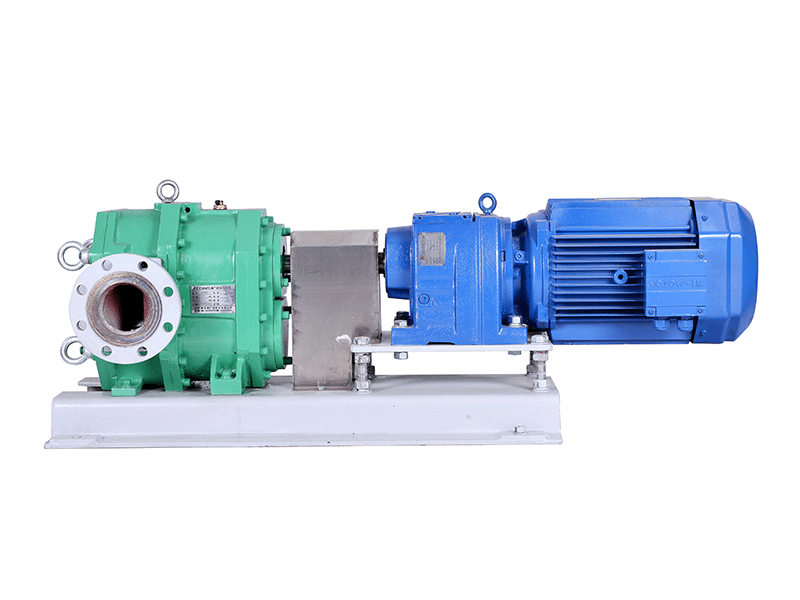

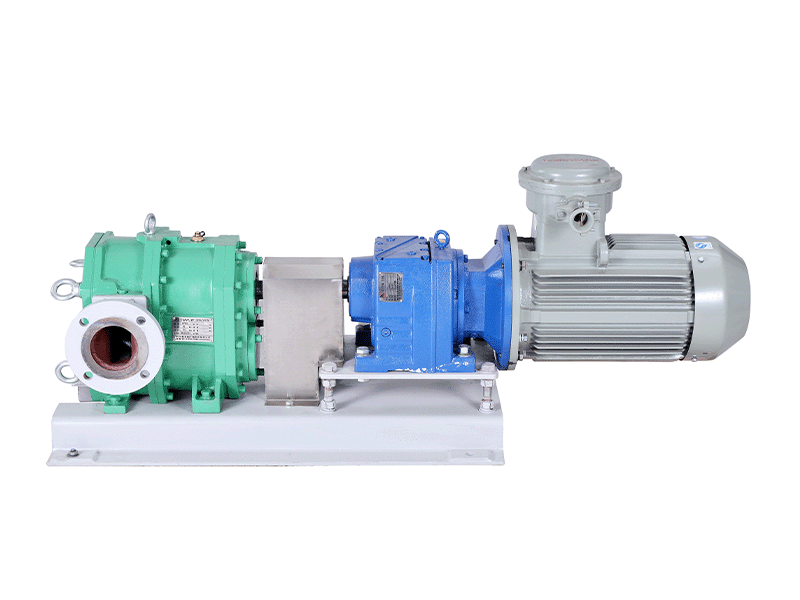

The rotary lobe sludge pump has the characteristics of strong self-priming ability, no clogging, and wear resistance, and can effectively transport sludge from low places to high places, meeting the requirements of the sewage treatment process.

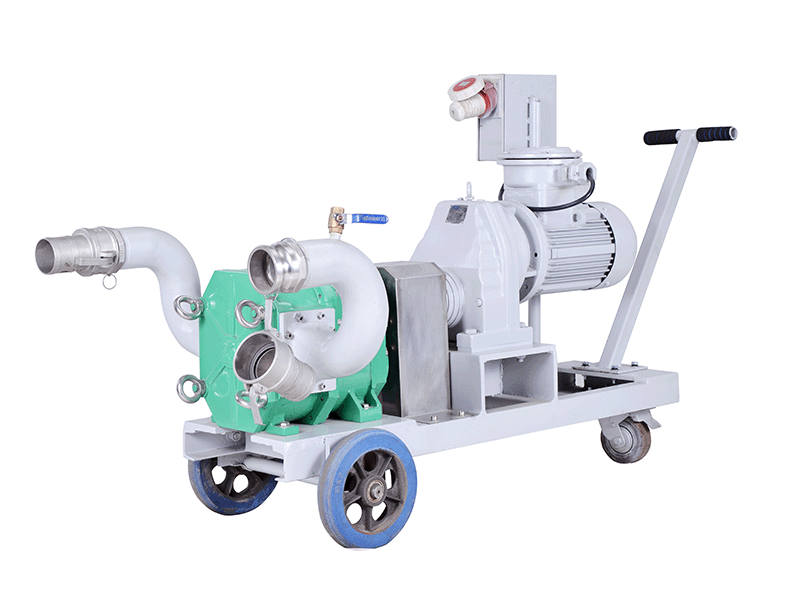

By lifting the impeller, it has the best hydraulic design, without winding and clogging. The sealing of its shaft and oil chamber is advanced and reliable, and it also has anti-leakage protection, which further ensures the stability and stability of the sludge pump in use. Reliability; the installation of the Rotary lobe sludge pump is very convenient and quick. It can be applied to any shape of pool. The advantage is that it occupies a small area. In addition to some of the advantages we mentioned above, the operation of the Rotary lobe sludge pump is very convenient. It is simple, generally quick to get started, and people can easily master its working essentials. Moreover, this kind of Rotary lobe sludge pump is also very simple to repair after failure. The matching motor has small power and will not be like some other pumps. Produces a lot of noise.

- 1. Wide applicability: suitable for transporting various high-concentration sludge, liquid containing particles and high-viscosity media, such as sewage, sludge, chemical raw materials, etc.

- 2. High efficiency: Due to its unique design, the Rotary lobe sludge pump can effectively transport high-concentration liquids, improving work efficiency.

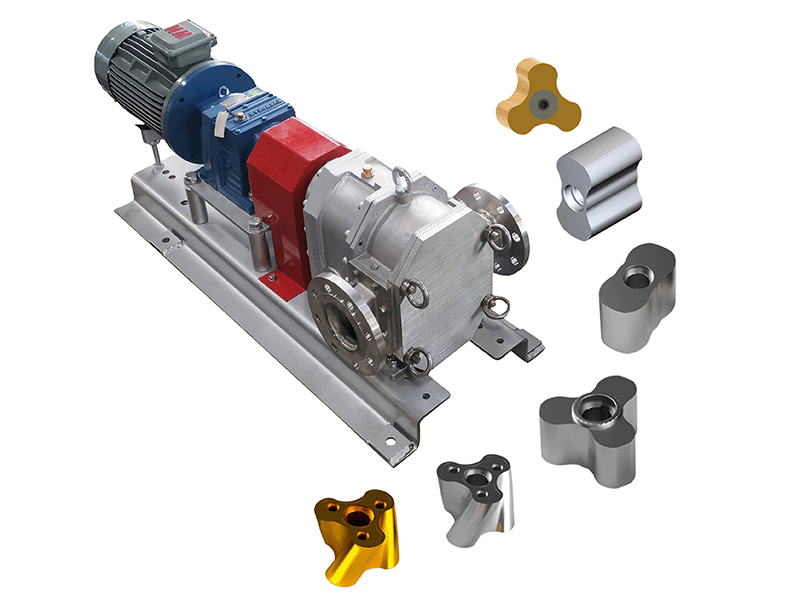

- 3. Corrosion-resistant and wear-resistant: The pump body and rotor are usually made of wear-resistant materials, which can resist the erosion of granular materials and extend the service life.

- 4. Good self-priming ability: It has good self-priming performance and can suck liquid into the pump and start working in a short time without additional auxiliary equipment.

- 5. Stable operation: The rotor pump has a simple structure, stable operation, low failure rate, and can work stably for a long time, reducing downtime and lowering maintenance costs.

- 6. Pulsation-free conveying: Due to the working principle of the pump, there is almost no pulsation when conveying fluid, which is beneficial to conveying dense media.

- 7. Adjustable flow: The flow can be adjusted by adjusting the rotation speed of the rotor or changing the number of rotors to meet different process requirements.

- 8. Energy saving and environmental protection: Compared with traditional centrifugal pumps, Rotary lobe sludge pump s generally have lower energy consumption, helping to save energy and reduce environmental pollution.

- 9. Anti-clogging: The design of the Rotary lobe sludge pump enables it to smoothly pass through impurities such as animal hair and long floc, avoiding the occurrence of clogging. At the same time, its regular and wide inlet design allows media that is viscous or contains solid particles to pass smoothly.

In summary, the Rotary lobe sludge pump has significant advantages in handling high-concentration sludge and media containing particulate matter, making it widely used in sewage treatment, sludge treatment, chemical production and other fields.

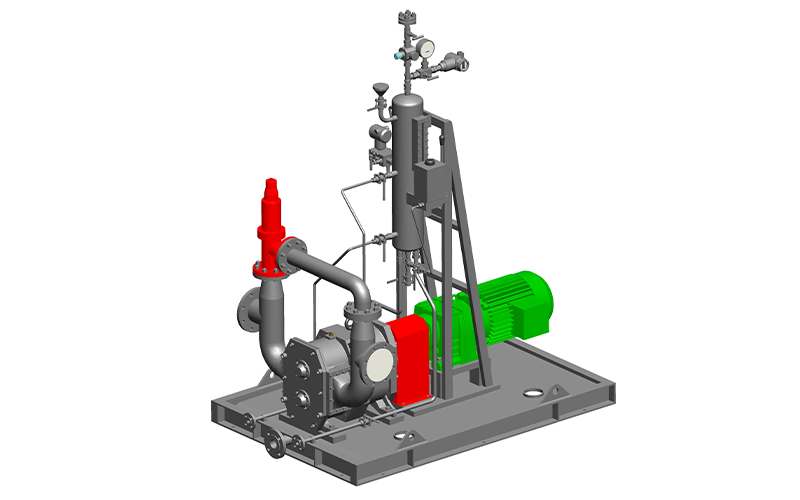

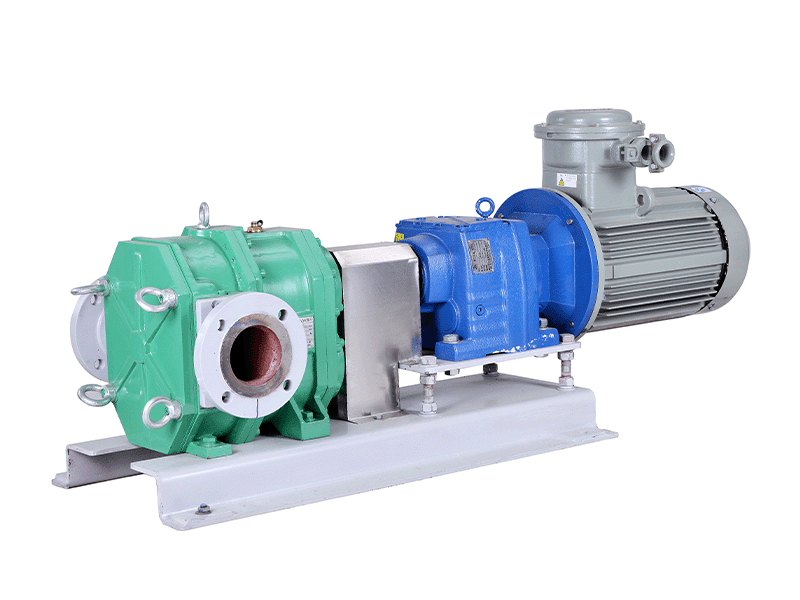

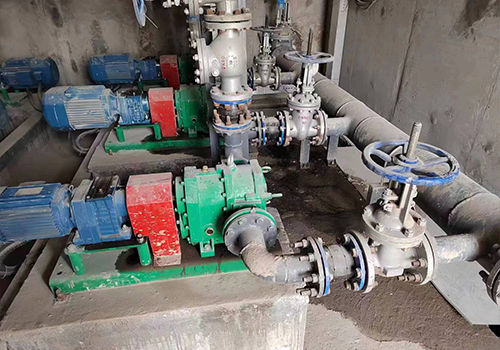

Because our country attaches great importance to water resources, many large sewage treatment plants use some Rotary lobe sludge pump s in their daily work. Therefore, Rotary lobe sludge pump s are widely used in sewage treatment plants. They are mainly divided into sludge return pumps and residual sludge pumps according to different models and application stations.

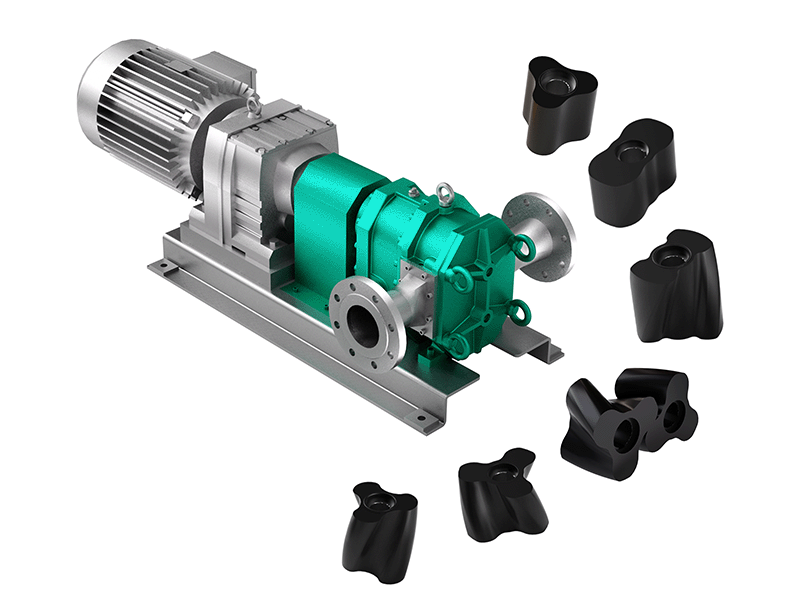

Among them, the Rotary lobe sludge pump is used as a residual sludge pump, which is mainly used to remove the remaining sludge in the sewage pool. The solid content of these sludges is generally between 2% and 4%. The sludge contains a lot of These particles are somewhat corrosive to the Rotary lobe sludge pump.Therefore, when using the Rotary lobe sludge pump , you need to equip it with some corrosion-resistant and wear-resistant rubber rotors.

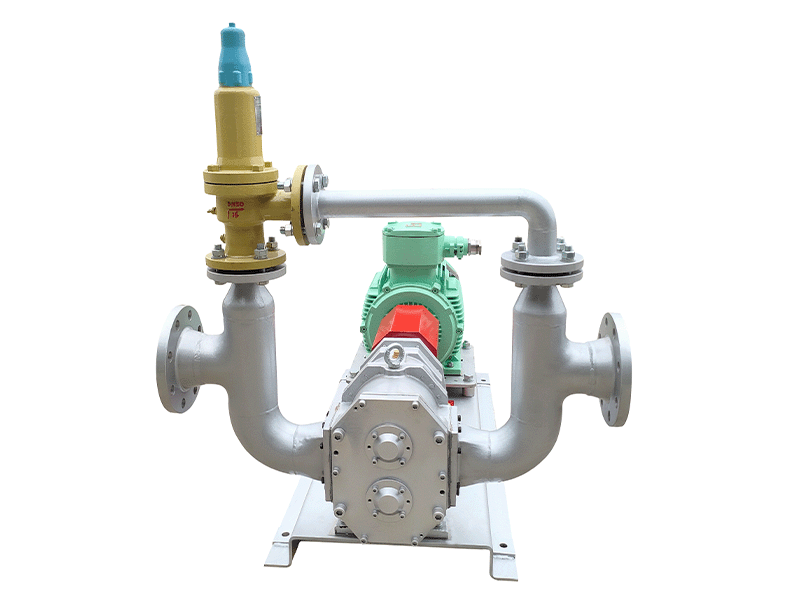

In terms of sludge return, the Rotary lobe sludge pump is mainly used as a special equipment for mixed liquid return and denitrification and denitrification in sewage treatment plants. It can also be used to pump purified water during ground drainage; irrigation and control waterway systems; and reprocessing during wastewater treatment. Circulation or mud suction circuits require micro-lift and large flow locations.

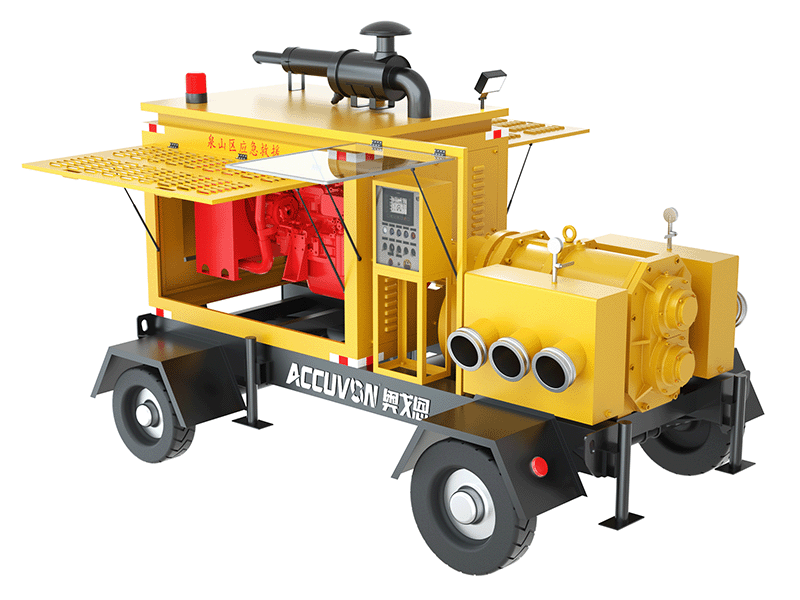

Rotary lobe sludge pump s have a wide range of applications in many industrial and municipal areas, including but not limited to:

- 1. Sewage treatment plant: used to transport solid particles and high-concentration sludge in sewage, including stirring, transportation and treatment during sewage treatment.

- 2. Sludge treatment equipment: used to transport and treat high-concentration sludge during sludge dehydration, concentration, drying and other processes, such as sludge dryers, centrifugal dehydrators, etc.

- 3. Chemical industry: used to transport high-viscosity media, chemical raw materials containing particulate matter, or wastewater, such as particle suspensions and wastewater treatment in the chemical production process.

- 4. Mining and metallurgical industry: used to transport high-concentration slurry and wastewater in the fields of ore beneficiation, mine wastewater treatment, tailings slurry transportation and other fields.

- 5. Food and beverage industry: used to transport wastewater, sludge and food raw materials containing particulate matter during food processing.

- 6. Papermaking industry: In the papermaking production process, it is used to transport paper pulp, waste paper pulp and wastewater, etc.

- 7. Fishery and breeding industry: used to transport wastewater, waste residue, etc. in breeding ponds.

- 8. Urban construction and environmental engineering: used in urban drainage systems, sewage treatment plants, rainwater collection and treatment systems and other fields.

In general, rotary lobe sludge pump s play an important role in situations where high-concentration sludge, particulate matter or high-viscosity media need to be transported, providing reliable transportation solutions for various industrial and municipal projects.