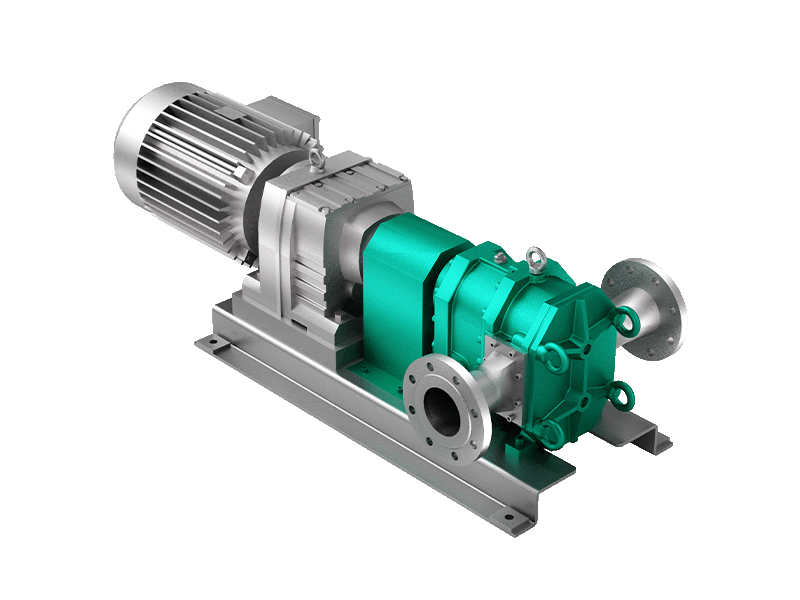

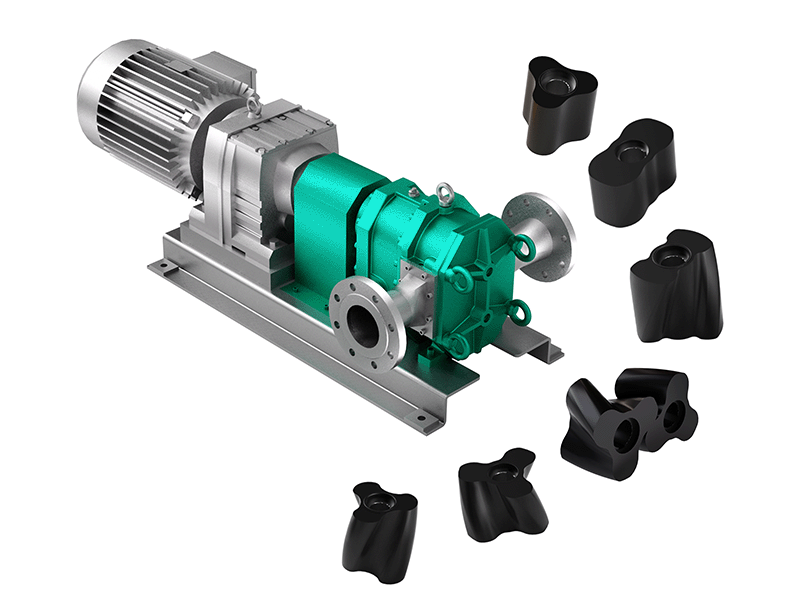

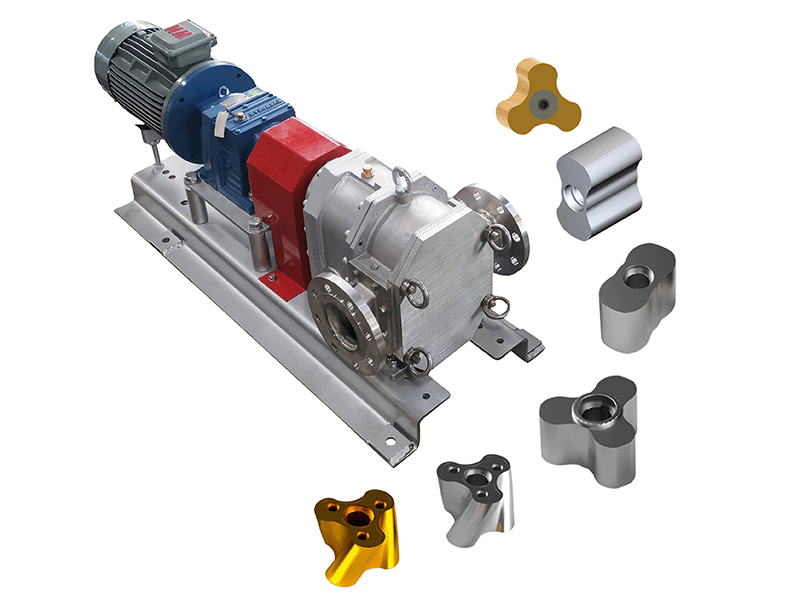

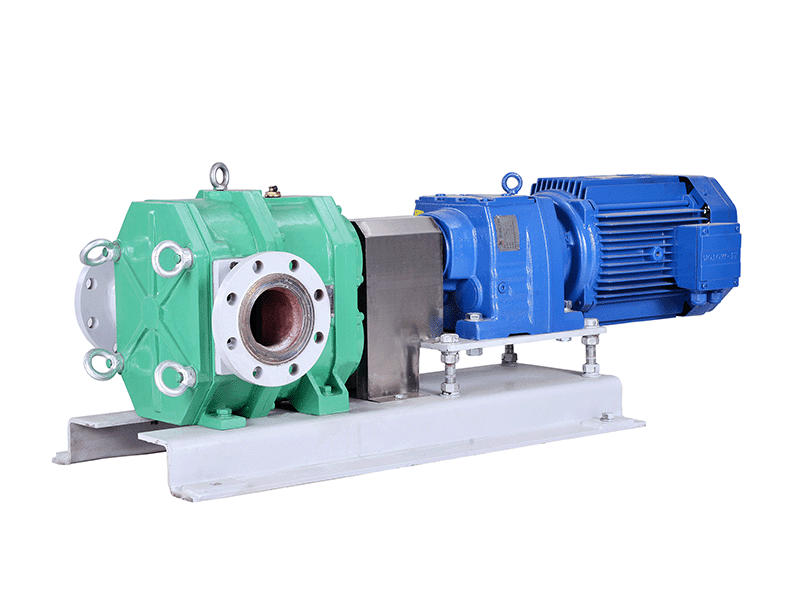

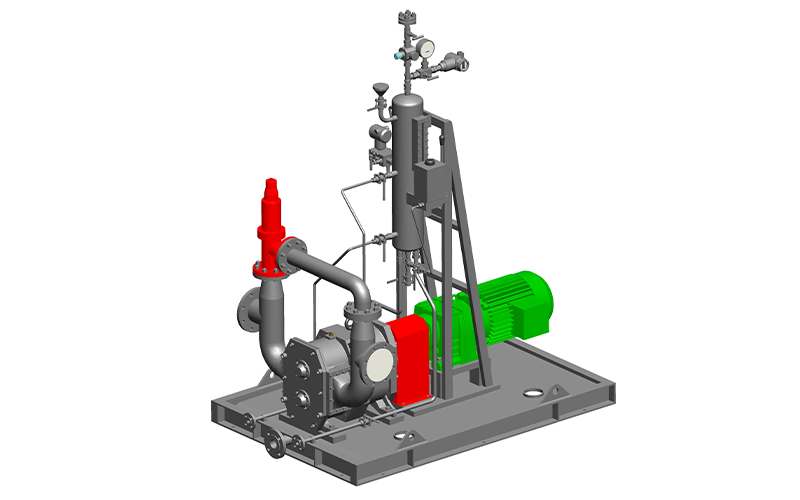

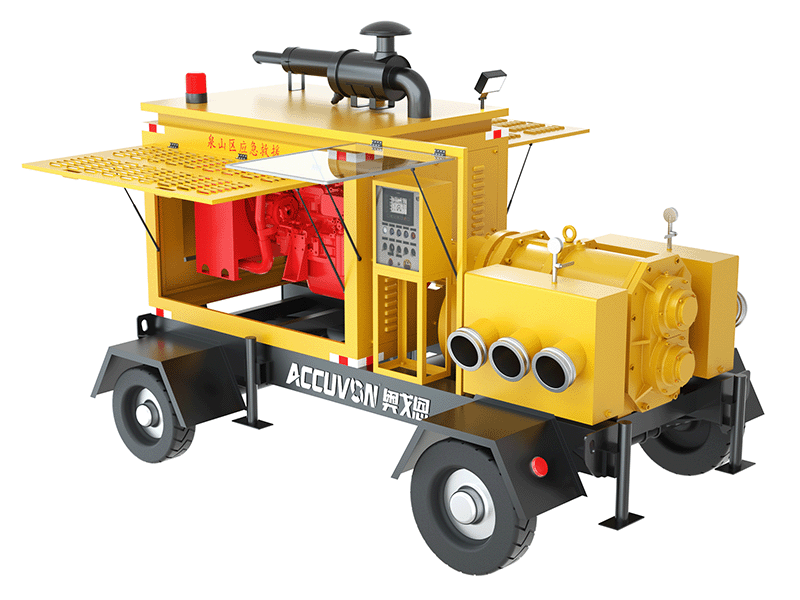

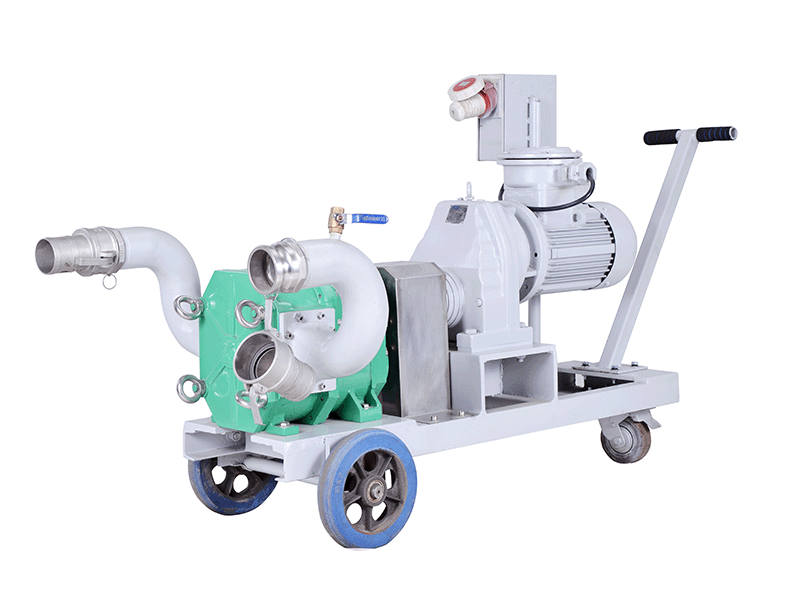

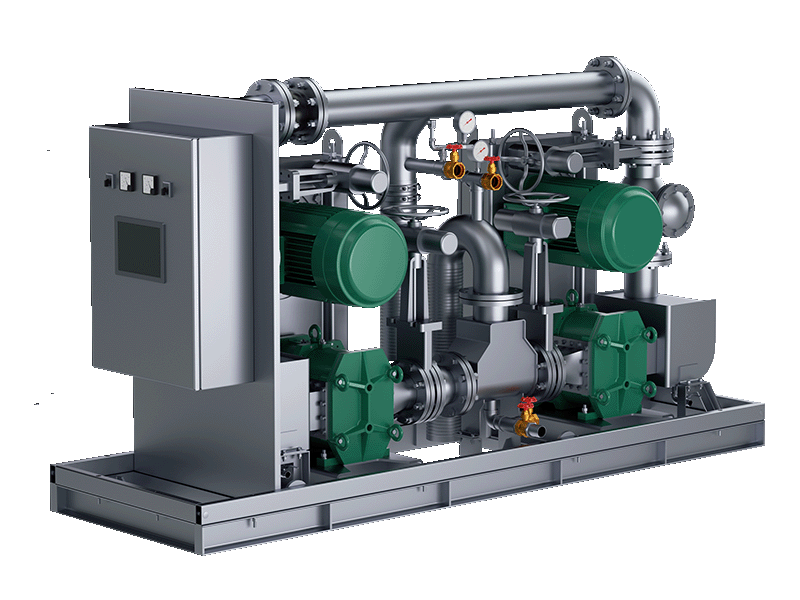

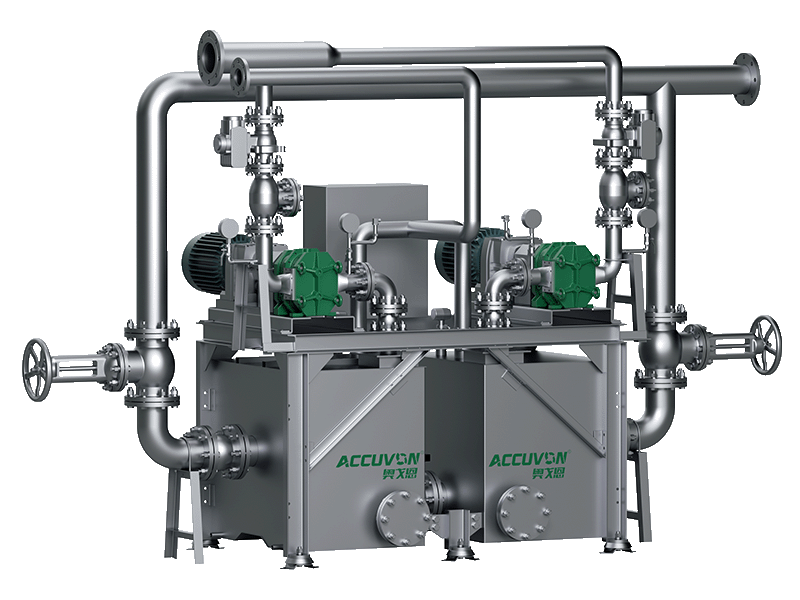

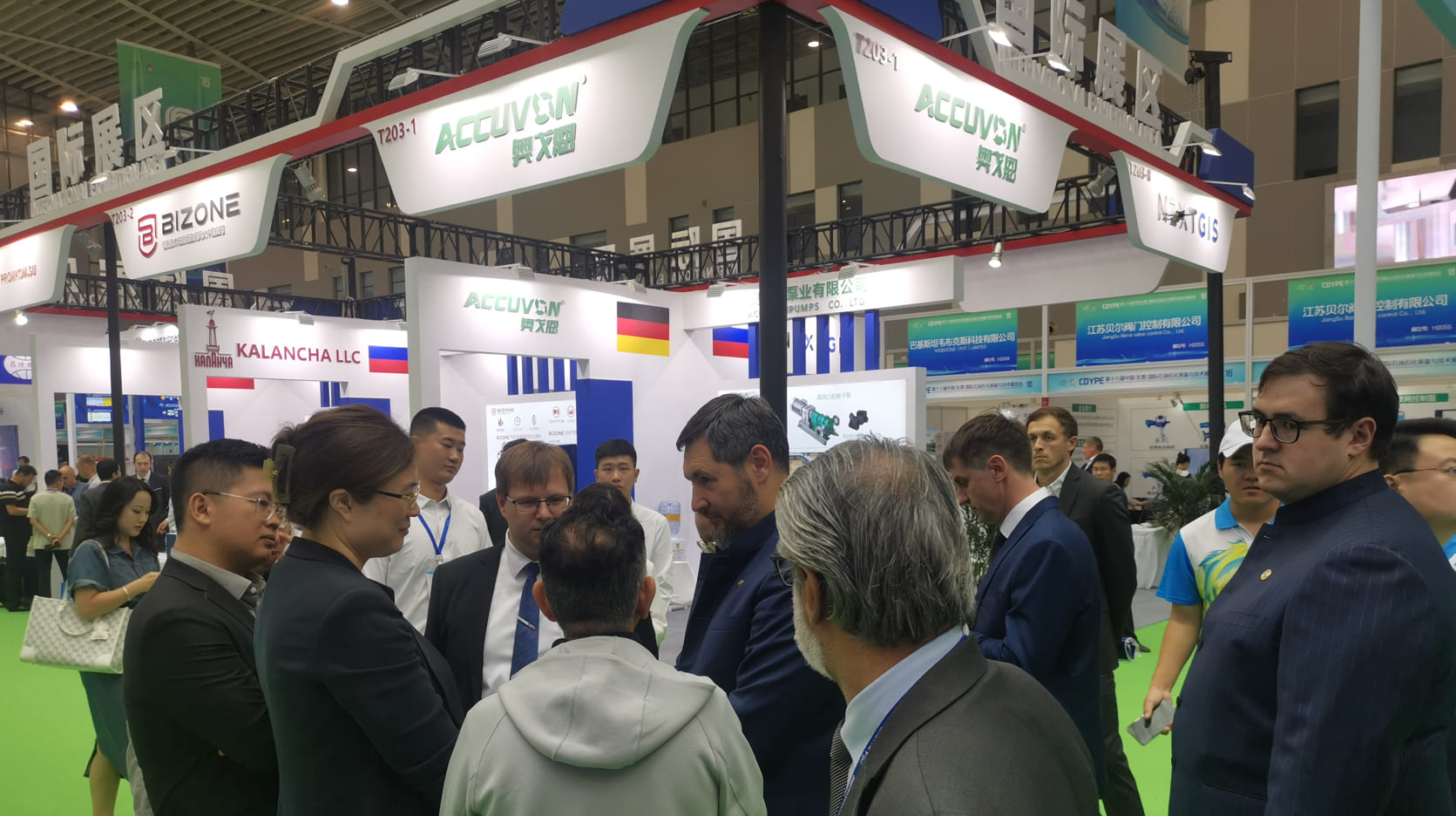

Accuvon (Guangzhou) Pumps Co., Ltd. is a Sino foreign joint venture registered and established in 2008. The core product of the company is the rotary lobe pump, mainly used in fields such as oil fields, refining, storage and transportation terminals. rotary lobe pump products have advantages such as strong self suction ability, wear resistance, and insensitivity to viscosity. They have obvious technical advantages in the treatment and transportation of dirty oil, sewage, sludge, and waste oil.

Accuvon Company has obtained the qualification of being a supplier for China National Petroleum Corporation and Sinopec, and has achieved many successful results in the oil and petrochemical industries such as oil fields, refining, and storage and transportation terminals.

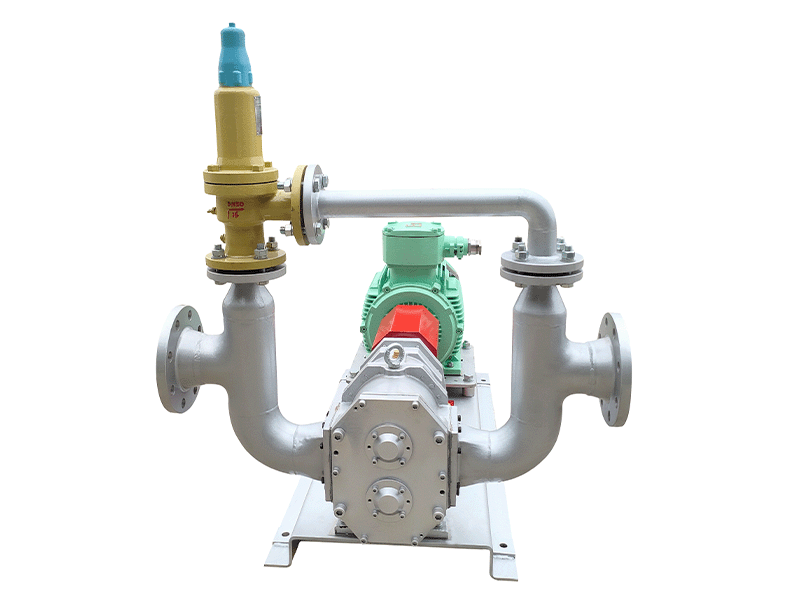

Lobe pumps are widely used in oilfield wastewater treatment, mainly in the following aspects:

1. **Conveying sewage and wastewater:** A large amount of sewage and wastewater will be produced during oilfield production, including production water, oil production sewage, domestic sewage, etc. Lobe pumps can be used to transport this sewage and wastewater from the production site to treatment equipment or treatment sites.

2. **Stirring and mixing:** Oilfield sewage often contains solid particles, grease and other substances, which require stirring and mixing to ensure treatment results. The lobe pump can effectively stir and mix the sewage through its rotational motion, and evenly disperse the solid particles in it, which helps to improve the efficiency of subsequent treatment.

3. **Dosing and mixing:** During the oilfield sewage treatment process, it is usually necessary to add chemicals for dehydration, deodorization, disinfection and other treatments. The lobe pump can be used in the dosing and mixing process to evenly mix the chemicals into the sewage to ensure that the chemicals are fully effective.

4. **Improvement and discharge:** After the sewage treatment is completed, the treated clean water needs to be discharged or reused. The lobe pump can be used to lift the treated clean water and transport it to the discharge outlet or reuse equipment to achieve rational utilization of resources and environmental protection.

5. **Filtration and separation:** Lobe pumps can be used in conjunction with filters, separators and other equipment to filter and separate solid particles and grease in sewage to improve treatment efficiency and water purity.

In general, lobe pumps play an important role in oilfield sewage treatment, which can help oilfields achieve effective treatment of sewage and resource recycling, and achieve the goals of environmental protection and sustainable development.

Lobe pumps have some significant application advantages in sludge treatment, including:

1. **Efficient transportation:** The cam pump can efficiently transport high-viscosity sludge. Even if the sludge contains a large amount of solid particles or oil, it can be effectively transported to the processing equipment or processing site.

2. **Strong stability:** The cam pump has stable flow and pressure output, which can ensure the continuous transportation of sludge under different working conditions and improve the stability and consistency of the treatment process.

3. **Wide adaptability:** The cam pump can handle sludge of different viscosities and particle sizes. It has strong adaptability and is suitable for various types of sludge treatment scenarios, including crude oil pollution, oil field sewage treatment, etc.

4. **Pulsation-free transportation:** The cam pump achieves continuous and uniform sludge transportation through the movement of the rotating cam without pulsation, which is beneficial to reducing the generation of bubbles and uneven mixing in the sludge.

5. **Low shear effect:** The operating characteristics of the cam pump make it less shearing when transporting sludge, which can reduce the crushing of solid particles in the sludge and the separation of oil quality, which is beneficial to maintaining the consistency and stability of the sludge. sex.

6. **Energy saving and environmental protection:** The design and working principle of the cam pump enable it to achieve efficient energy conversion. The energy loss during the transportation process is small, and the energy saving effect is obvious, which is conducive to reducing energy consumption and reducing environmental pollution.

In summary, the cam pump has the advantages of high efficiency, stability, and wide adaptability in sludge treatment. It can help achieve effective transportation and processing of sludge, improve treatment efficiency and quality, and reduce costs and environmental pollution.