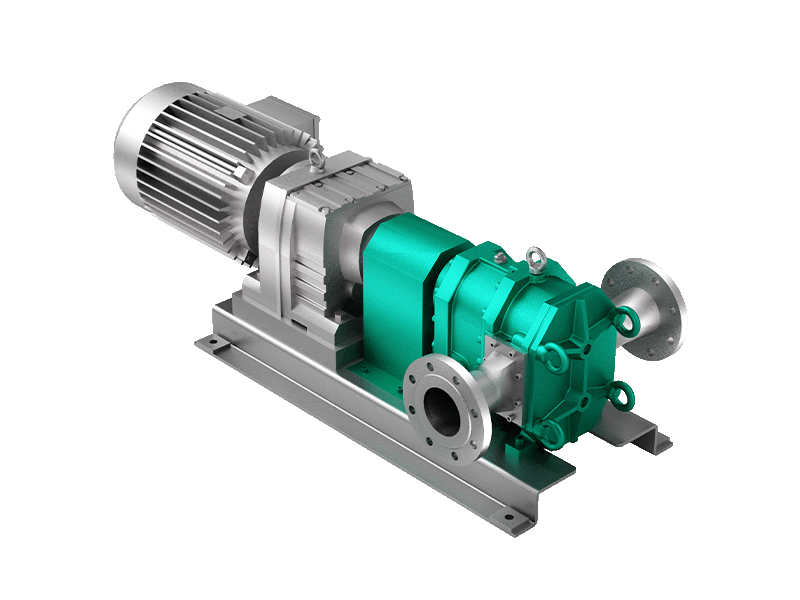

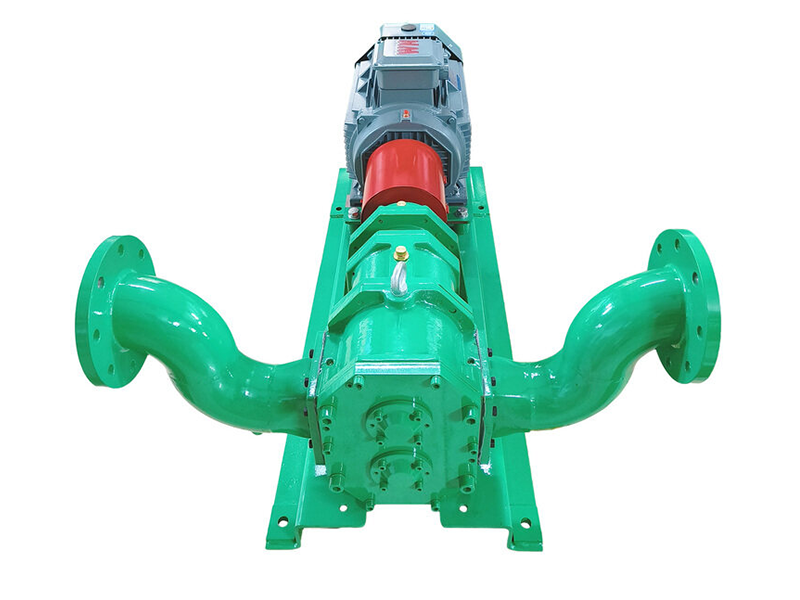

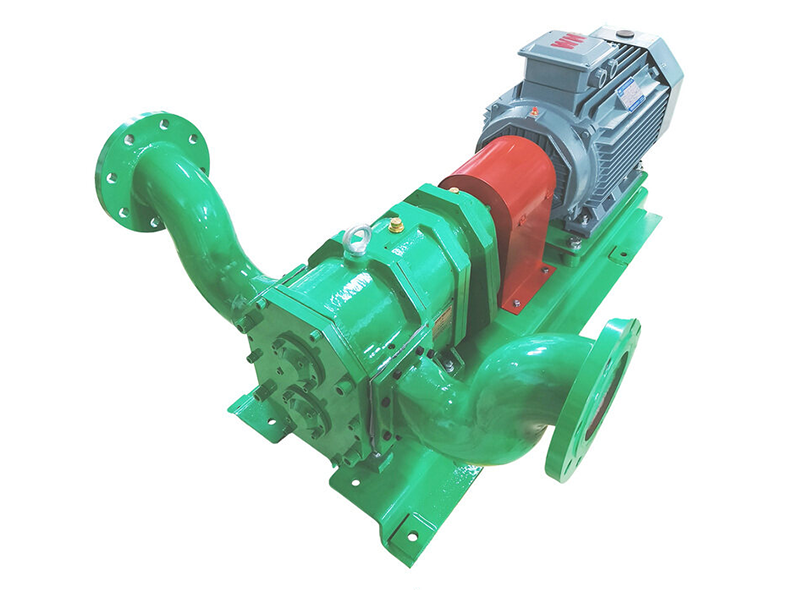

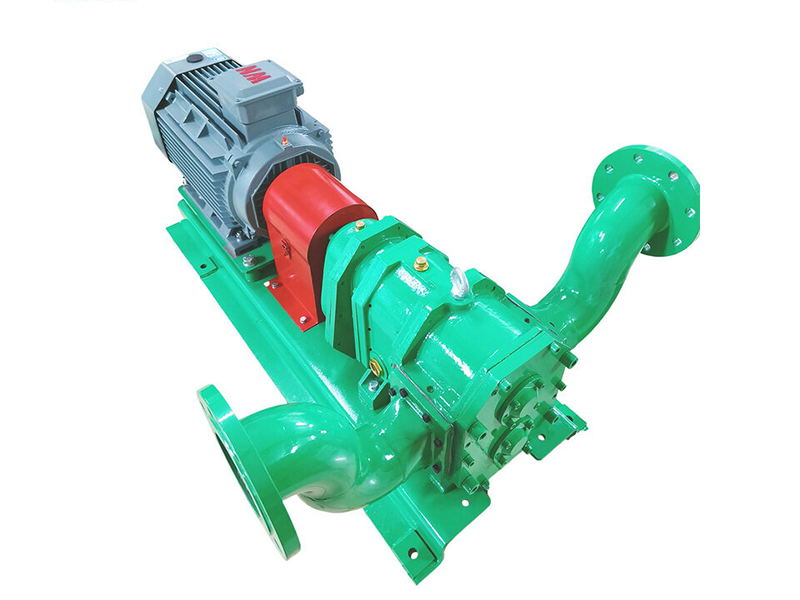

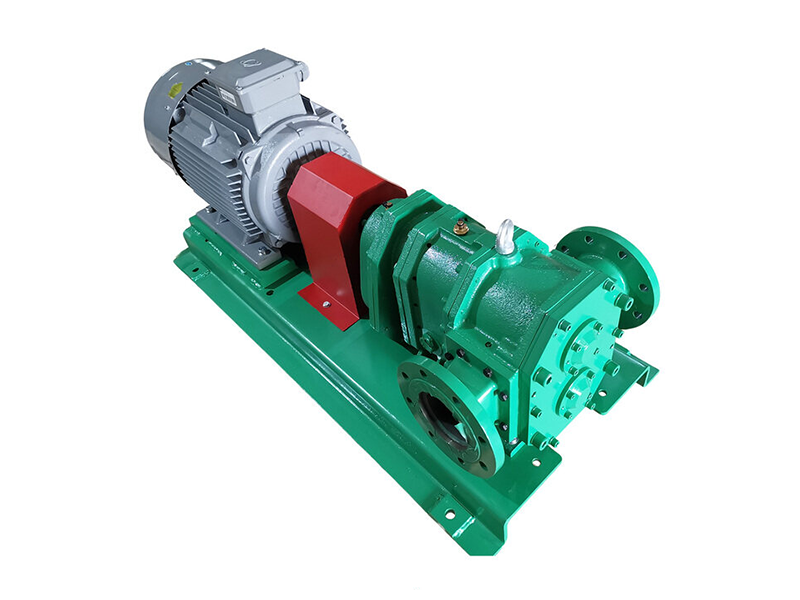

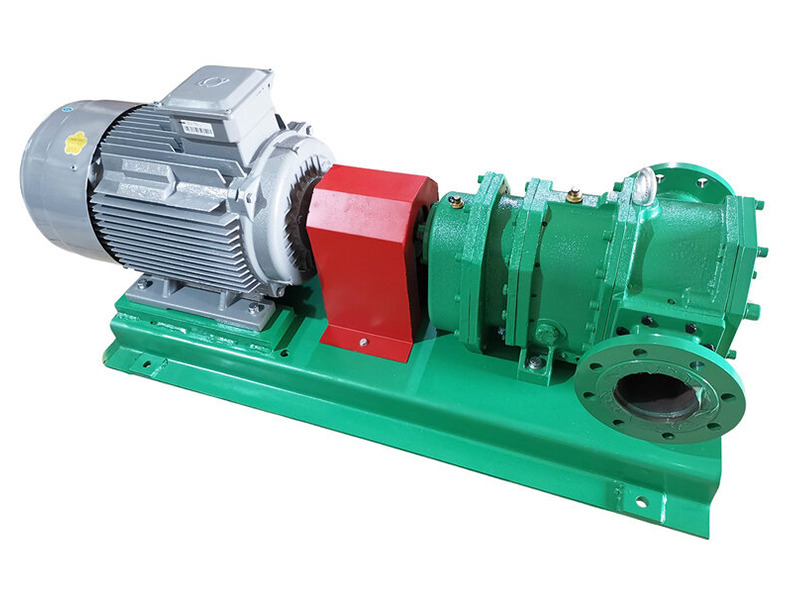

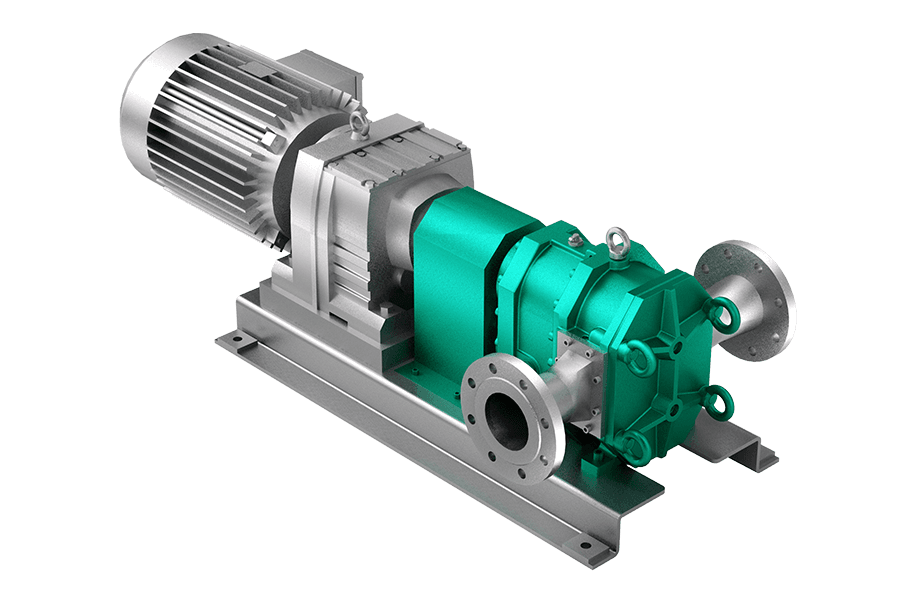

• Self-priming, valveless, positive displacement pump

• Designed with two shafts with parallel axes

• The shafts move relatively to one another thanks to external timing gear

• The displacers (=rotors) roll off each other with minimum axial and radial clearance

• In every position, the rotors and casing close the suction chamber against the pressure chamber

• Gentle, low-pulsation pumping

• For viscous, solid, abrasive or shear-sensitive media

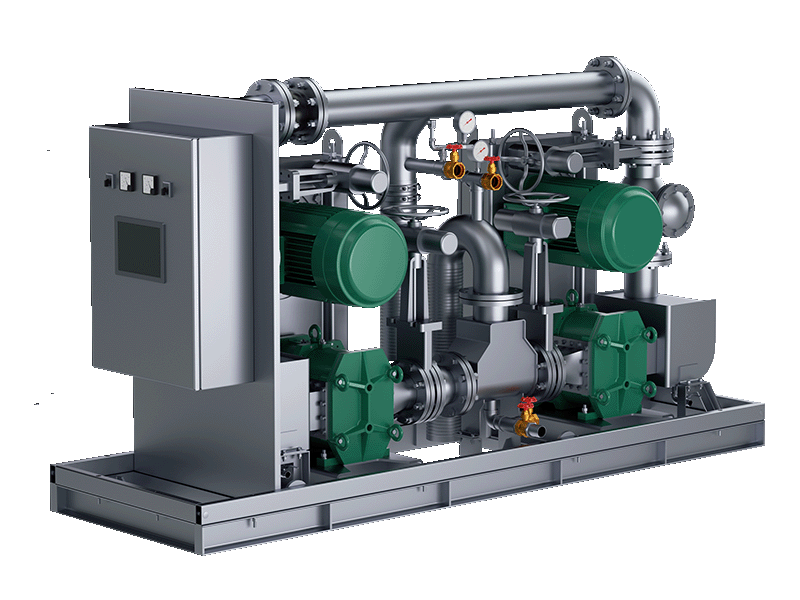

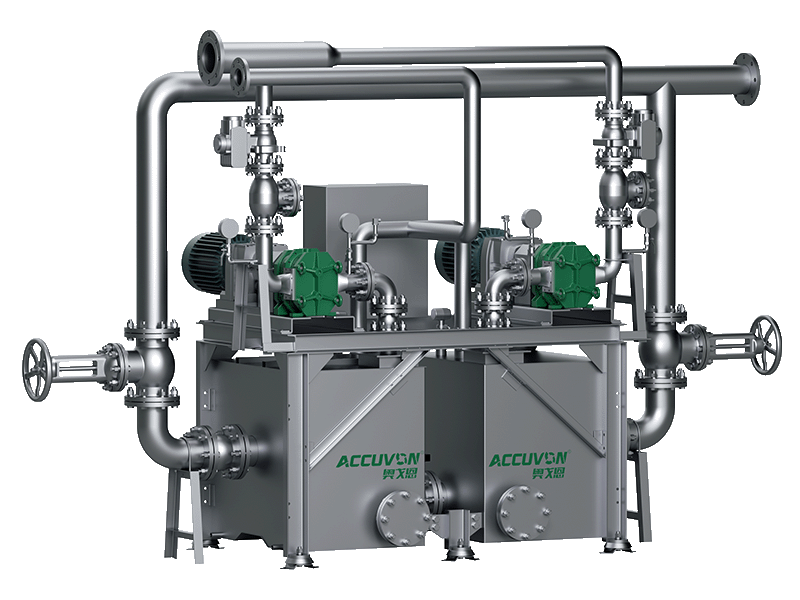

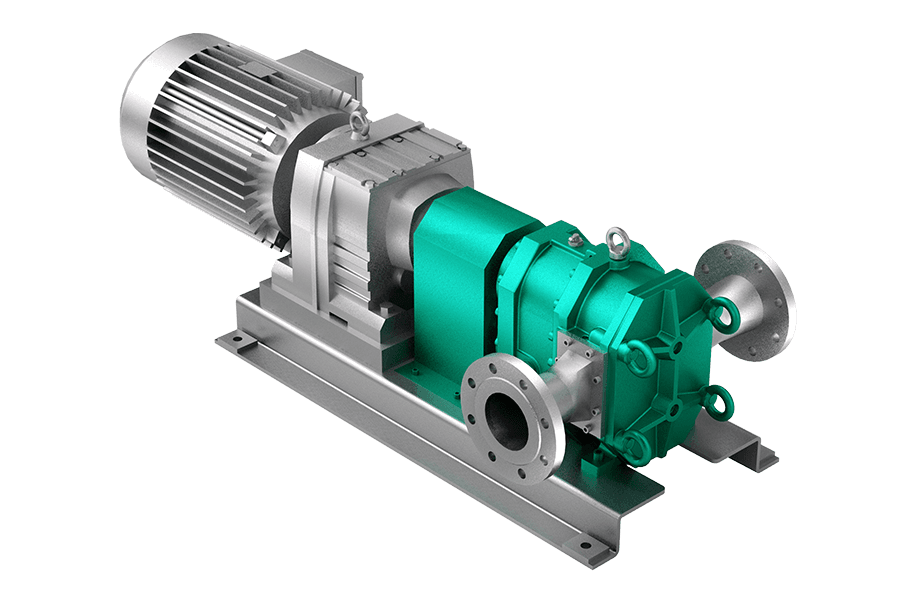

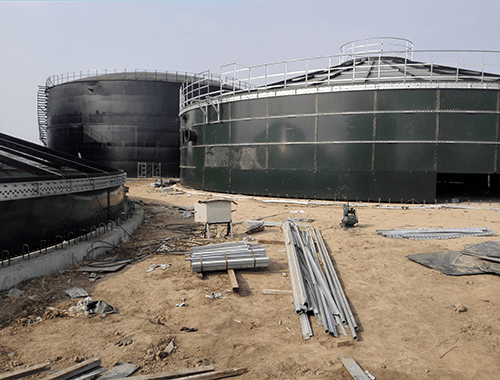

The Accuvon rotary lobe pump is a highlight of the biogas system (Accuvon can provide a complete set of equipment from the addition of processing raw materials to the output and separation of biogas slurry: raw material addition and transportation equipment - biogas tanks - biogas slurry output and separation equipment). Compared with traditional single-screw conveying biological raw materials, the characteristics and advantages of rotary lobe pumps are quite obvious.

- 1) When the rotary lobe pump transports medium, the medium is filled in the closed cavity formed by the rotor and the inner wall of the pump, and is discharged as the cavity moves. Therefore, the rotary lobe pump is most suitable for transporting materials such as biogas raw materials with high particle content and particle diameter. large medium;

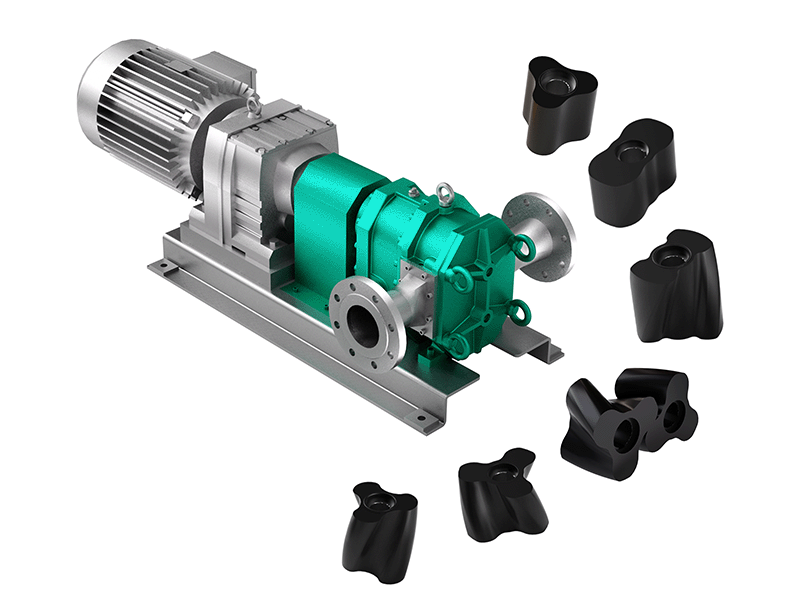

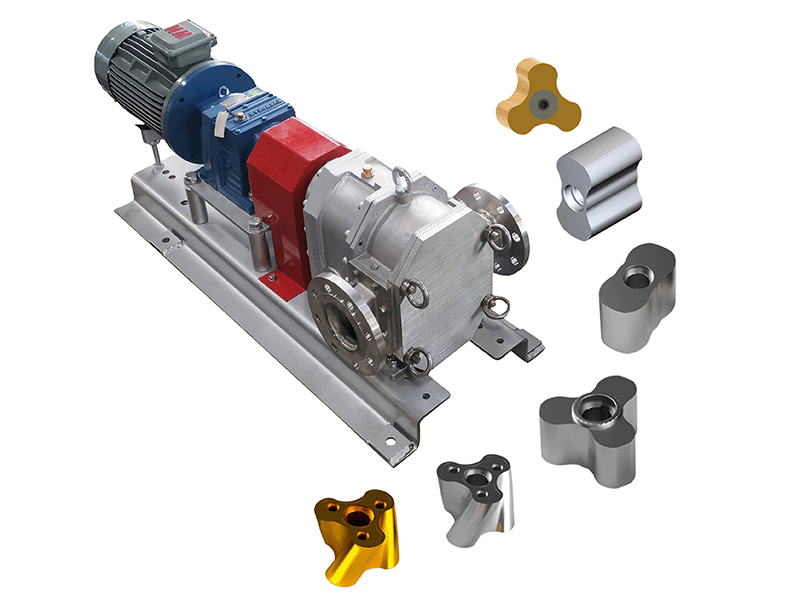

- 2) The delivery component of the Accuvon rotary lobe pump is two rotary lobe rotors in elastic contact (it can also be a special rotor for metal biogas), and the rotors are available in a variety of materials and structures that are both wear-resistant and adaptable;

- 3) Accuvon rotary lobe pump also has the advantages of online maintenance, compact structure, small footprint, few wearing parts (only a pair of rotors and mechanical seals), and long service life of wearing parts;

- 4) The rotary lobe pump is a highly efficient positive displacement pump. Under the same working conditions, its starting torque and operating torque are lower than that of a single screw pump. From the perspective of saving energy consumption, the Accuvon rotary lobe pump is the first choice for the transportation of biological raw materials.

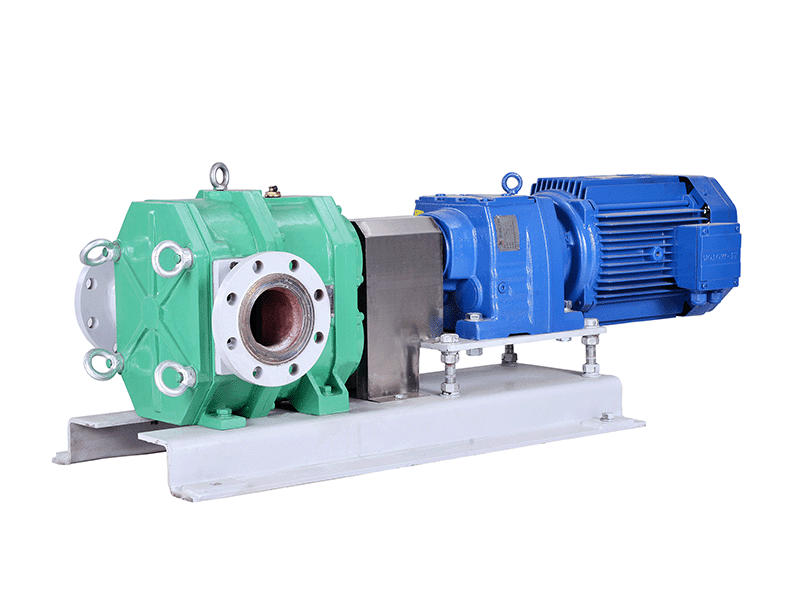

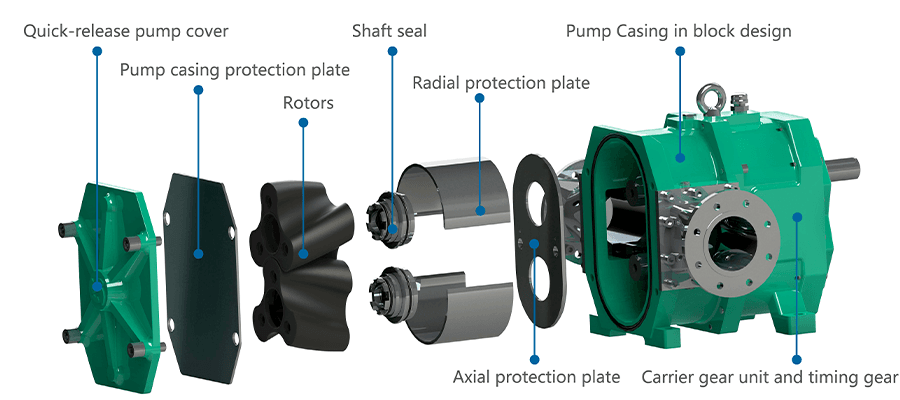

Design and material selection of main components of Accuvon rotary lobe pump

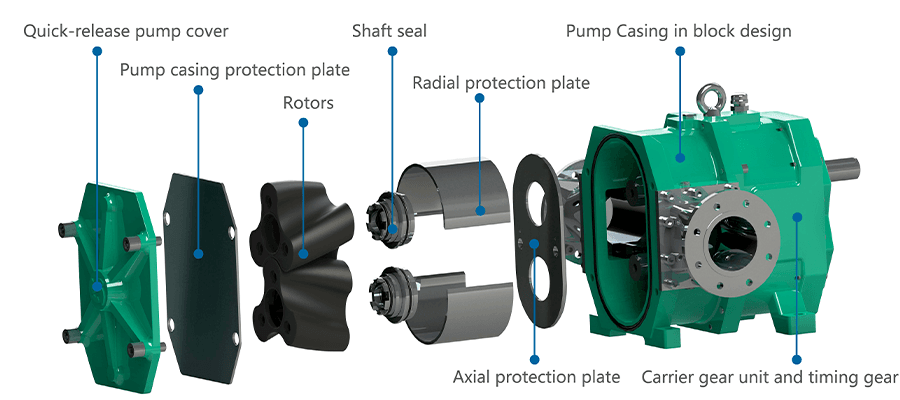

Pump casing:

- ★ Overall casting

- ★ Surface gray cast iron (GG25)

- ★ Surface hardening treatment; axial protective lining plate is available; radial protective lining plate is optional;

- ★ All wearing parts (including lining plates) can be replaced in the pump chamber without disassembling the pump body or pipelines.

Bearings: Double bearings on one side; soaked in lubricating oil in the casting cavity, with oil drain holes on the side;

Shaft: made of carbon steel; not in contact with the medium at all; lubricated by oil.

Shaft seal: no maintenance required; single mechanical seal; both mechanical seals immersed in lubricating oil (cannot be lubricated with grease).

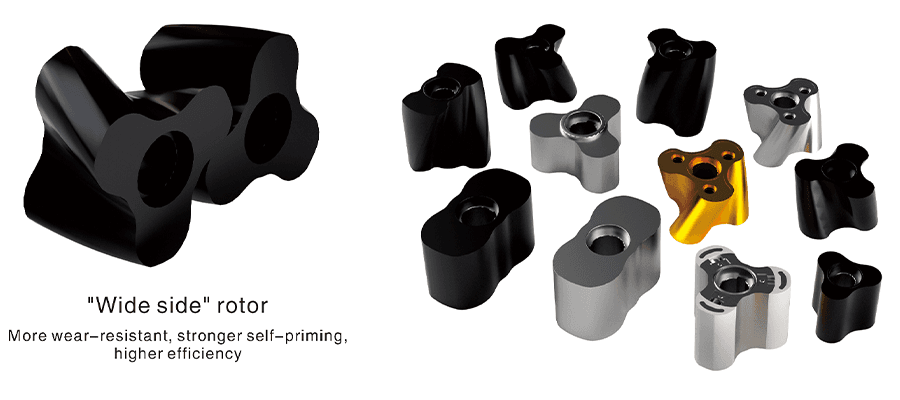

Rotors: A wide variety of rotors are available.

Seal monitoring: The middle isolation chamber is filled with lubricating oil, which can not only lubricate the mechanical seal but also the connection between the rotor and the shaft. connecting device); and can monitor whether the mechanical seal is in good condition (when the mechanical seal is damaged, oil will overflow from the spiral hole under pressure).

Maintenance: Accuvon pumps use online maintenance, which only requires opening the pump cover sealed by an O-ring.

Connection: With DIN standard flange, the flange is made of steel and the surface is galvanized.

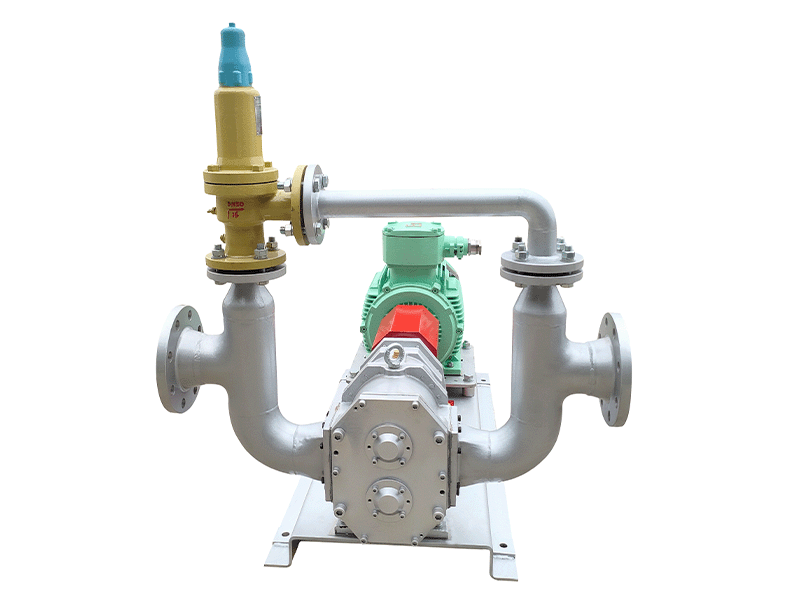

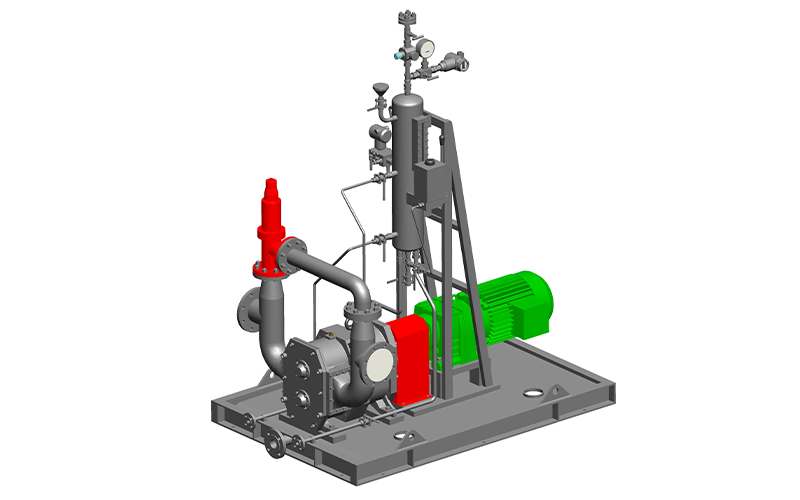

Equipment assembly: pump, motor, flange, base, Rotex coupling and protective cover

Accuvon Rotary lobe Pump Performance and Structural Features

|

One. Wear resistant lining

In view of the grinding properties of the medium, the Accuvon rotary lobe pump provides a four-sided fully lined protection structure. The pump chamber is designed with two axial protective lining plates and two radial protective lining plates;

- 1. Axial protective liners are standard, and radial protective liners are optionally used when conveying highly abrasive media;

- 2. The material of the lining plate is: hard steel 1.8714 (XAR400), which is laser hardened and has high wear resistance.

- 3. When the lining plate is worn, both the axial lining plate and the radial lining plate can be replaced directly in the pump chamber through the opened pump cover.

No need to disassemble the pump body or piping.

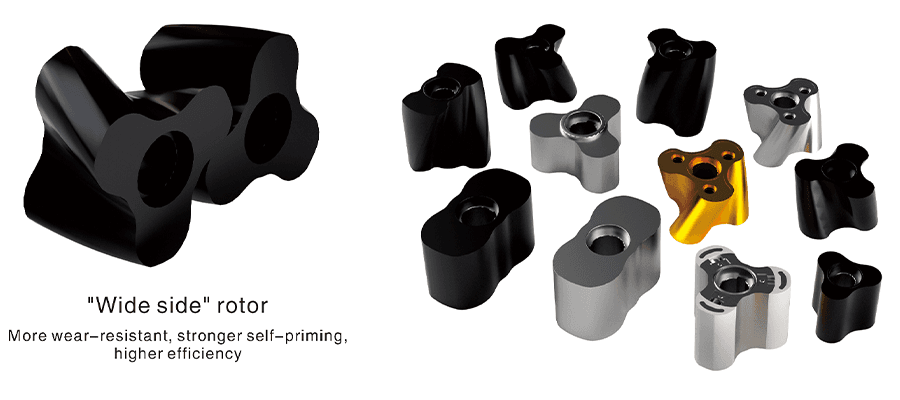

Two. rotor

- 1. Accuvon rotary lobe pumps are available in a variety of rotor types;

- 2. The completely rubber-coated rotor is the standard configuration of the OGORN rotor pump; the outer layer of the rotor is completely covered with rubber material, and the inner rotor core is GGG40;

- 3. The rotor tip replaceable rotor is another Accuvon technology used in the biogas field; detailed description: After the rotor is used for a period of time, the tip is often worn, but the rotor body is intact. At this time, the worn rotor tip can be replaced. The intact rotor body continues to be used. This not only prevents backflow caused by wear, but also maintains stable and efficient transportation. It also further extends the operating life of the rotor and reduces maintenance costs.

- 4. The Premium rotor (two-blade wide-side optimized tip groove metal rotor) is Accuvon's biogas-specific rotor. It adopts the design concept of two-blade wide-side large spiral. The two-blade wide-side design can seal the sealing state between the rotor and the inner wall of the pump. The point seal is improved to a line seal to prevent backflow caused by wear and maintain stable and efficient transportation. For rotors with metal rotor tips that have grooves: the media itself gets stuck in the grooves and is permanently renewed with each rotation of the rotor. The wear rate of this organic short-term surface is ideally 100%. On the other hand, the optimized rotor itself shows almost no wear, even under long-term load. This type of rotor further extends the rotor life and reduces maintenance costs.

Three. axis

The shaft of the Accuvon rotary lobe pump is not in contact with the fluid medium at all and is lubricated by oil. It is precision machined. The oversized shaft diameter and step-free design avoid rotor wear caused by shaft offset; ensure the transmission of energy; ultra-large shaft diameter. High standard shaft components, maintenance-free for life. If the shaft is damaged due to any non-human factors, Accuvon manufacturer will be responsible for free replacement.

Four. Bearings and gears

Bearings: Double bearings on one side; soaked in lubricating oil in the casting cavity, with oil drain holes on the side;

Gears: Use high-end turning centers, CNC high-speed hobbing machines, and CNC gear grinding machines to ensure precision; use high-quality low-carbon alloys

The gold steel is carburized and quenched to ensure strength; a cleaning phosphating line is used to clean and prevent corrosion.

Five. Machinery Seal

The shaft seal of the Accuvon rotary lobe pump is a maintenance-free single mechanical seal; both mechanical seals are soaked in lubricating oil (no oil

grease lubrication). At the same time, a middle isolation chamber is designed, which is filled with lubricating oil, which can not only lubricate the mechanical seal and the connection device between the rotor and the shaft, but also monitor whether the mechanical seal is in good condition (when the mechanical seal is damaged, Oil will escape from the spiral hole under pressure).

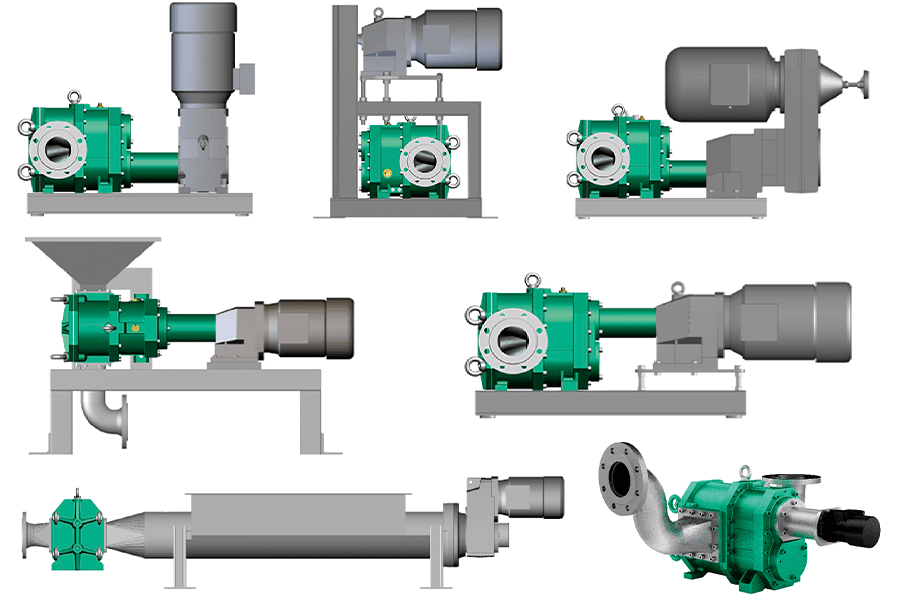

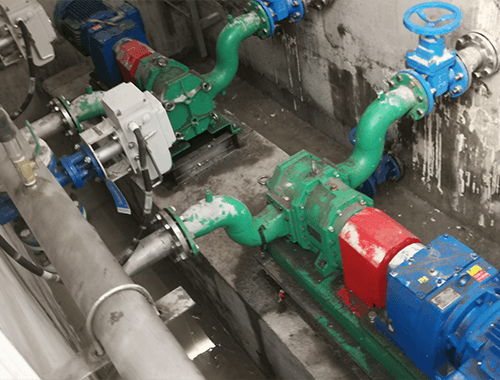

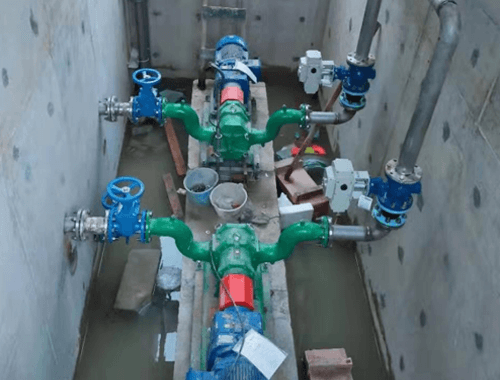

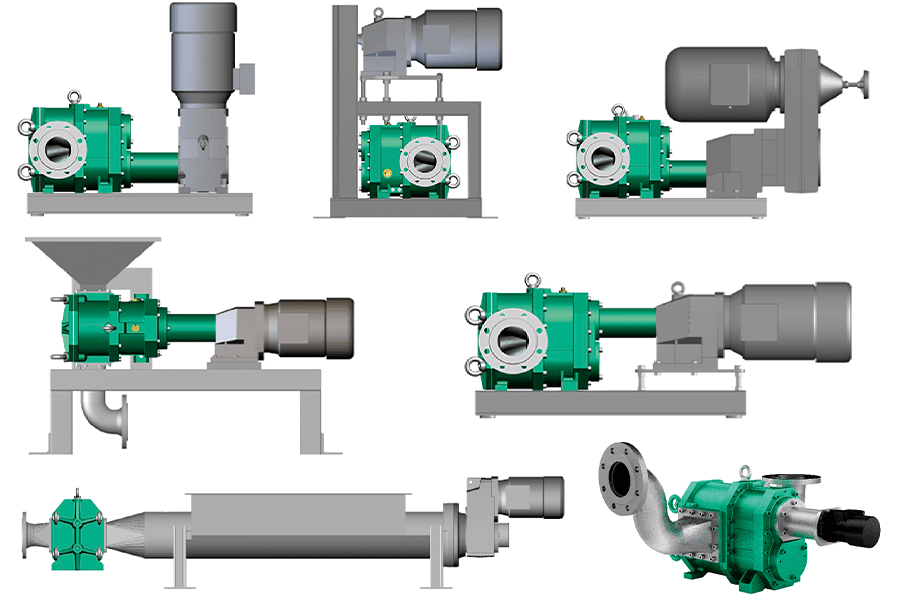

Common installation methods

|

Standard horizontal installation (equipped with gear reduction motor)

Hydraulic motor drive

Pulley upper and lower structure (for small spaces)

Three-point support method (PTO driven)

Submersible or semi-submersible installation (for special applications)

Rotary lobe pump combination with propeller filling (suitable for media with poor fluidity)

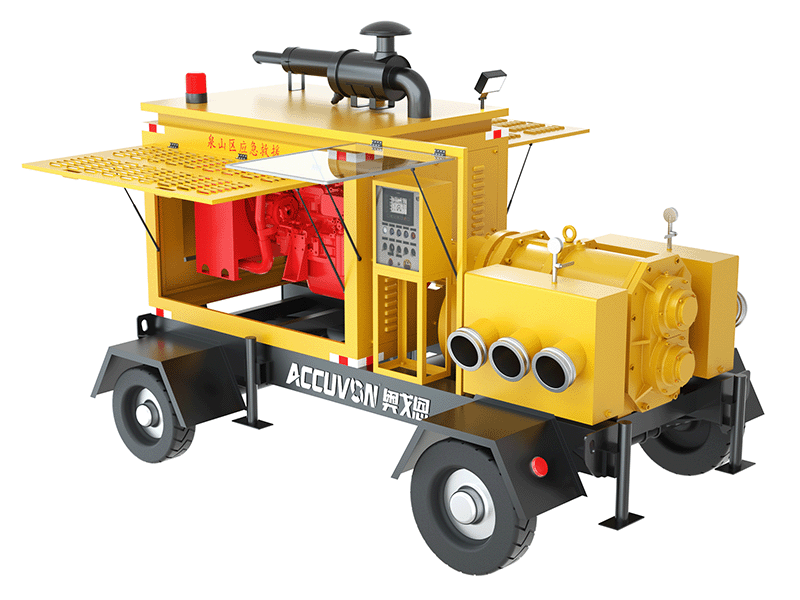

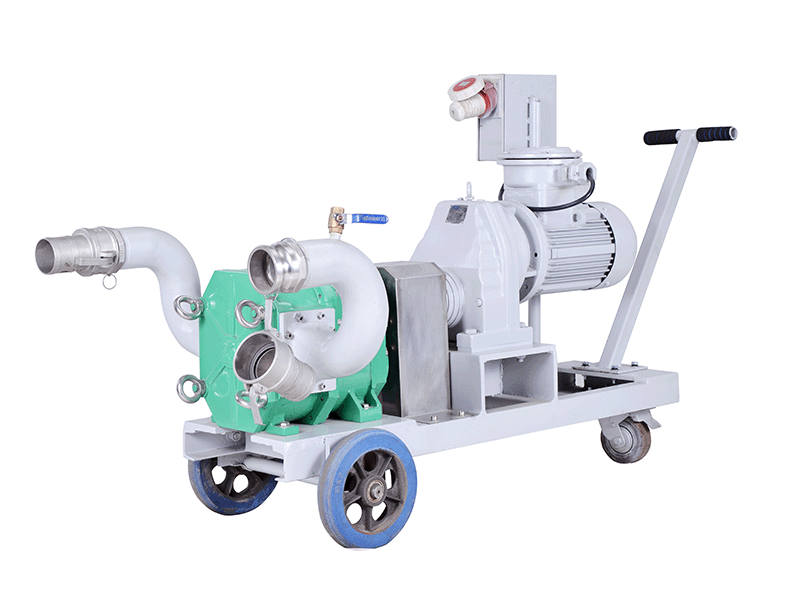

Mobile pumps can also be configured according to your needs:

Trolley - for repurposing

Trailer - electric motor or diesel engine as power source

Tank truck - space saving, installed on the tank truck

1. the Premium rotor (two-blade wide-side optimized tip groove metal rotor)

- 1)Premium, linear

- 2)Premium profile – of biogas rotors

- • Large sealing area

- • Patented geometry

- • Effective wiper edge

- • Pressure-resistant

- • Made of steel, stainless steel or plastic

2. axial and radial casing protection

3. Corrosion resistance: Biogas often contains corrosive elements such as hydrogen sulfide, which can damage traditional pumps. Biogas rotary lobe pumps are usually made of corrosion-resistant materials such as stainless steel or special coatings.

4. Wear resistance: Biogas may also contain solid particles that can cause wear on pump components. Rotary lobe pumps are designed to handle these particles without causing significant damage, extending the life of the pump.

5. Efficiency: Rotary lobe pumps are known for their high efficiency and reliability, making them suitable for continuous operation in biogas production facilities.

4. Variable speed operation: Some biogas rotary lobe pumps offer variable speed operation, allowing the operator to adjust flow to suit changing production needs or gas composition.

6. Minimal Maintenance: Compared with other types of pumps, biogas rotary lobe pumps have a sturdy structure and few moving parts, requiring minimal maintenance, thereby reducing downtime and operating costs.

Overall, biogas rotary pumps play a vital role in the efficient and reliable transfer of biogas within anaerobic digestion systems, helping to generate renewable energy from organic waste.