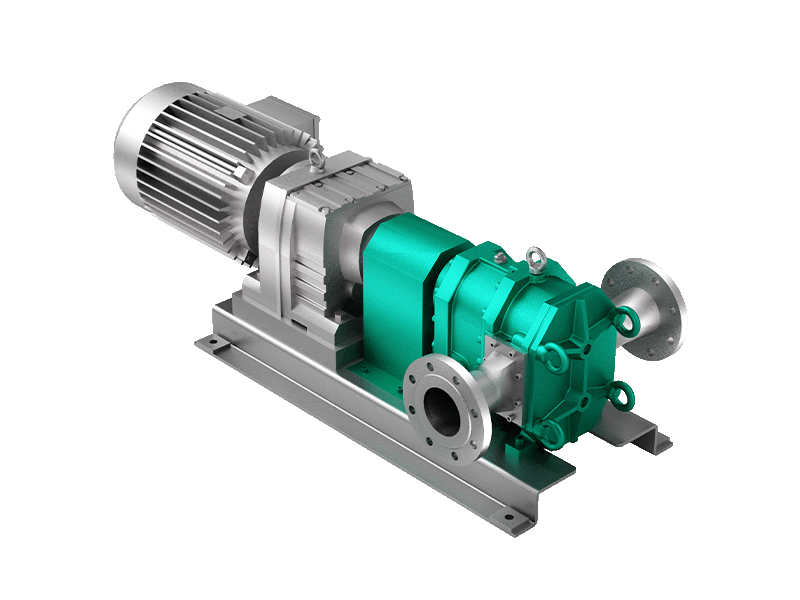

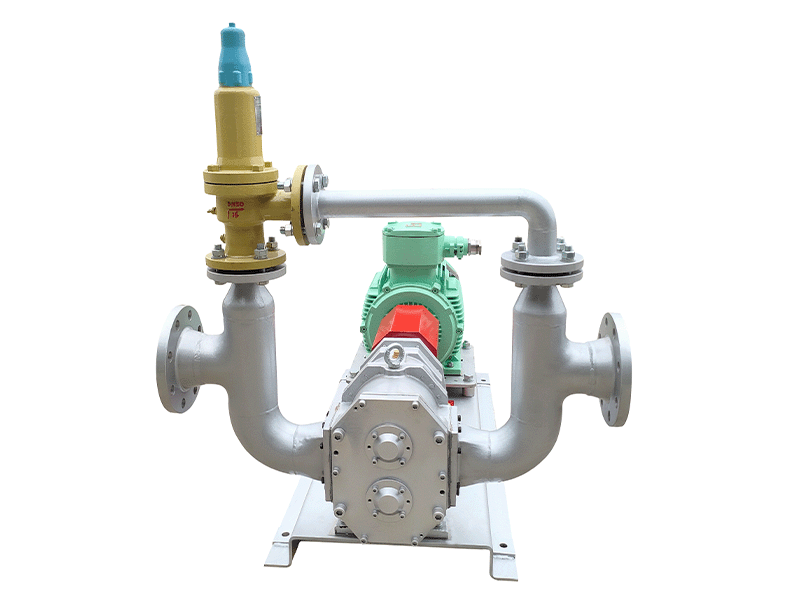

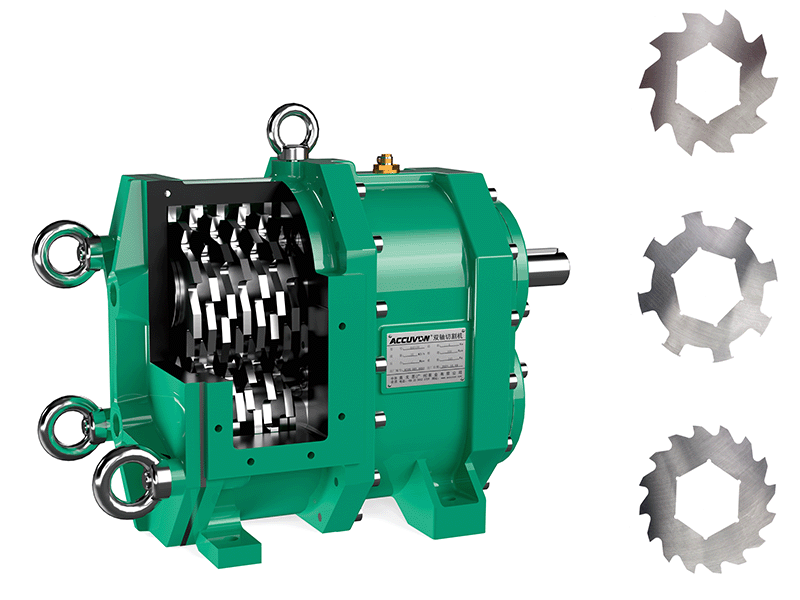

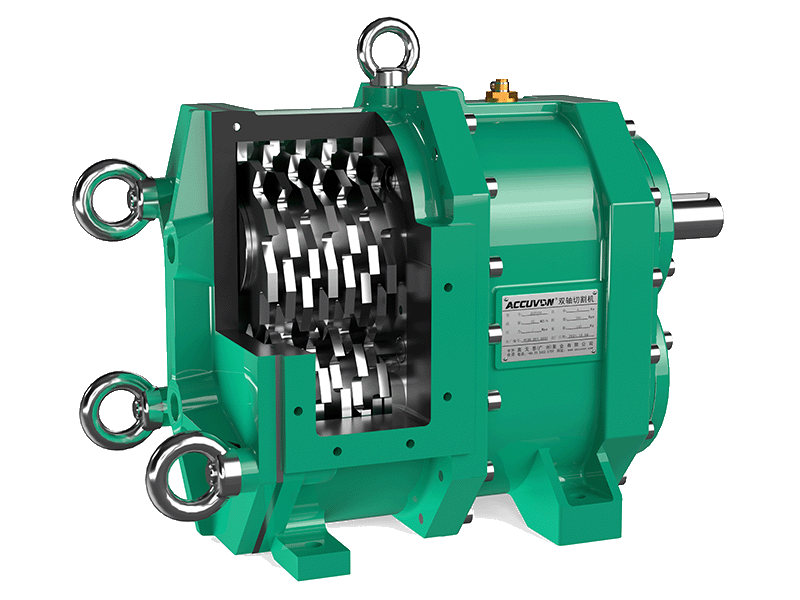

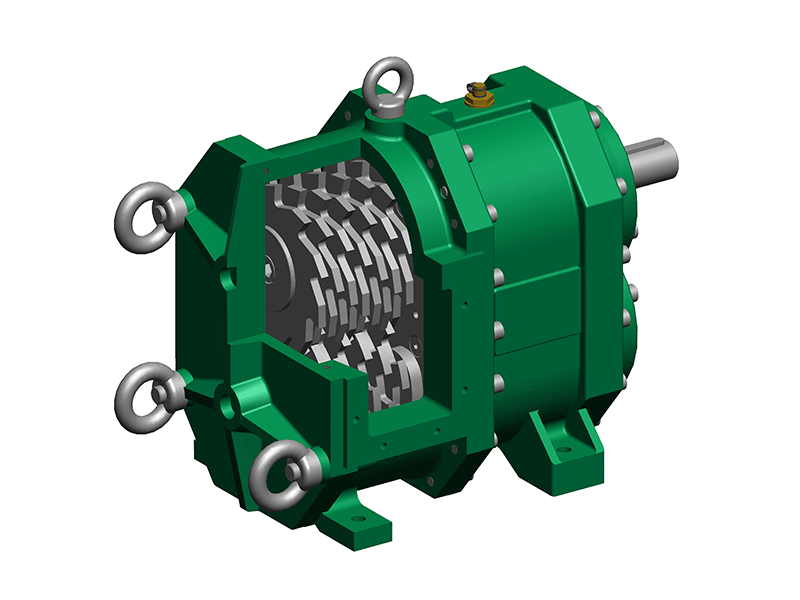

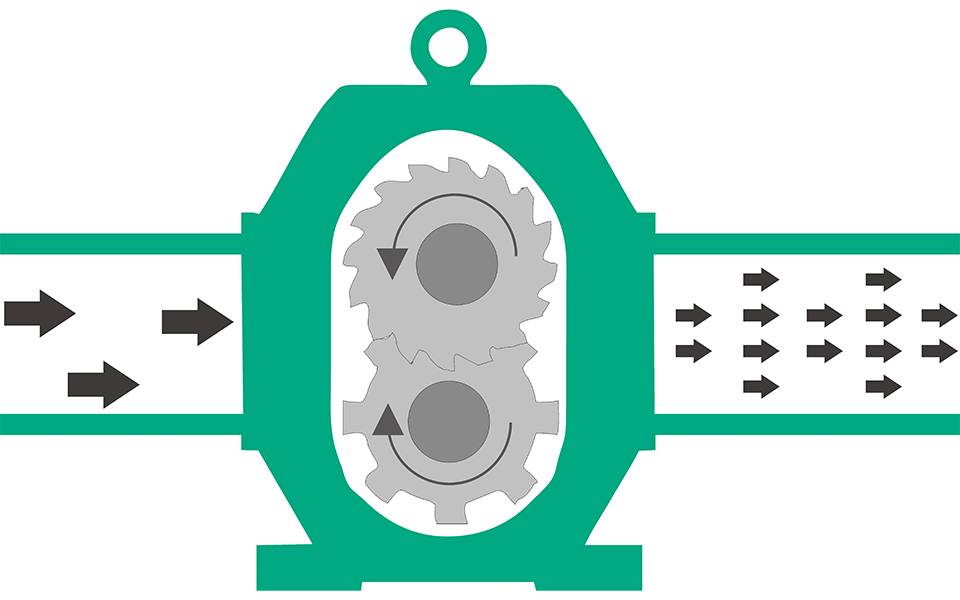

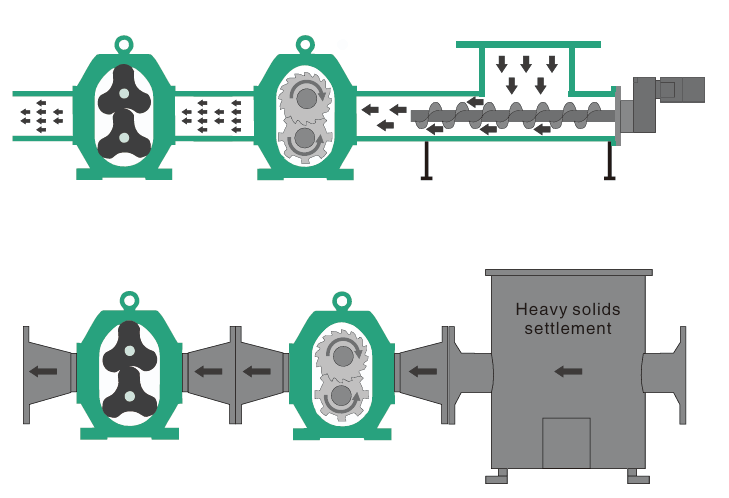

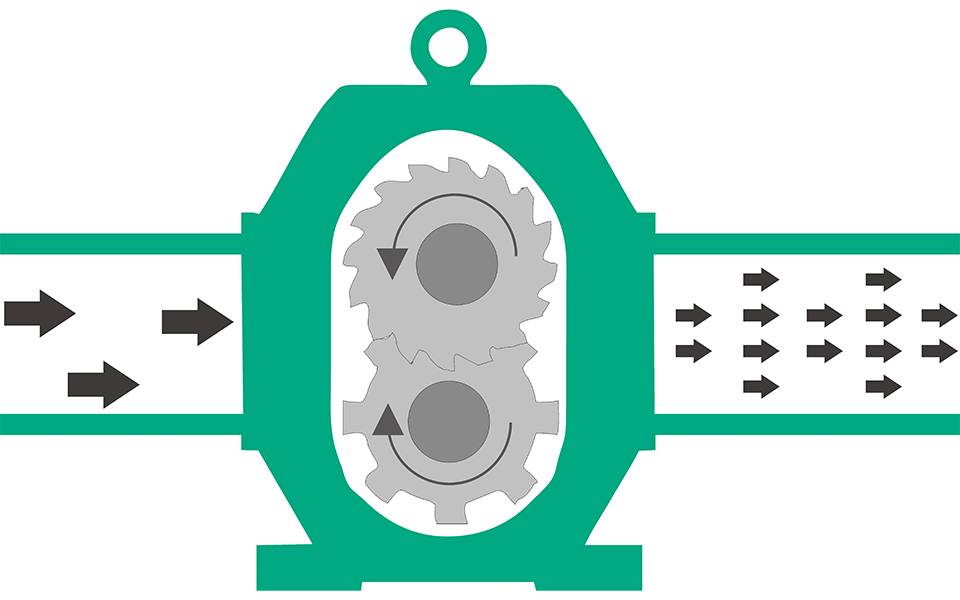

The Accuvon shear is an efficient and widely used shearing and crushing machine developed based on the design of the Accuvon rotary lobe pump. Therefore many parts on the two machines are interchangeable. The only difference compared to the rotary lobe pump is that the pump rotor is replaced with a shear blade. The cutting tool and blade are tightly fixed on two bearings. By adjusting the relative rotation speed of the two bearings, the best cutting effect is achieved and fiber objects are prevented from being wrapped around the cutter and blades. The cover is very convenient to open and the internal parts of the pump can be easily replaced.

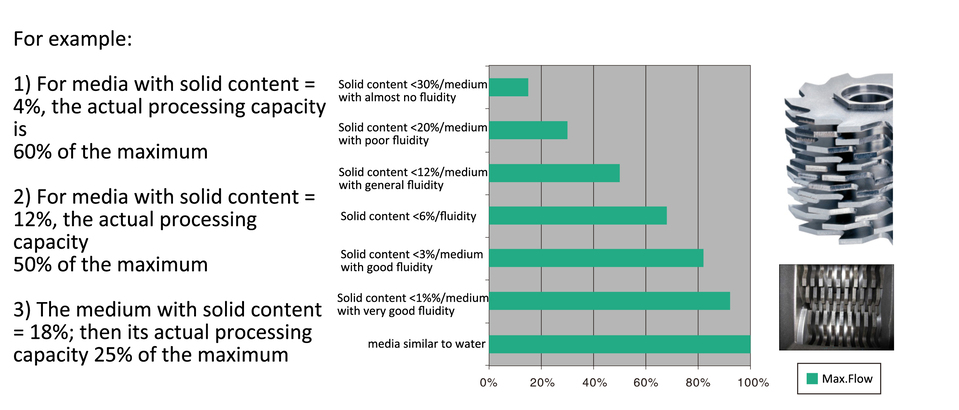

Two parallel shafts rotate in opposite directions driven by synchronized gears. The cutting blade and cutting gear installed on the shaft mesh and rotate with each other successively under the reverse rotation of the parallel shaft. The solid medium flowing through the cutting cavity is continuously squeezed, crushed and torn by the multiple extrusion of the cutting blade and cutting teeth. cracking and other effects, and finally achieve complete fragmentation. The rapid counter-rotation of the two parallel axes ensures perfect cuts and prevents the cutting parts from becoming entangled with fibers such as fur. We provide cutting tools of different sizes, which can be combined in any combination and matched with corresponding rotation speeds to meet the needs of different working conditions. At the same time, we can provide cutting parts made of special materials for cutting corrosive media. Accuvon multicrushers can even be used in seawater media.

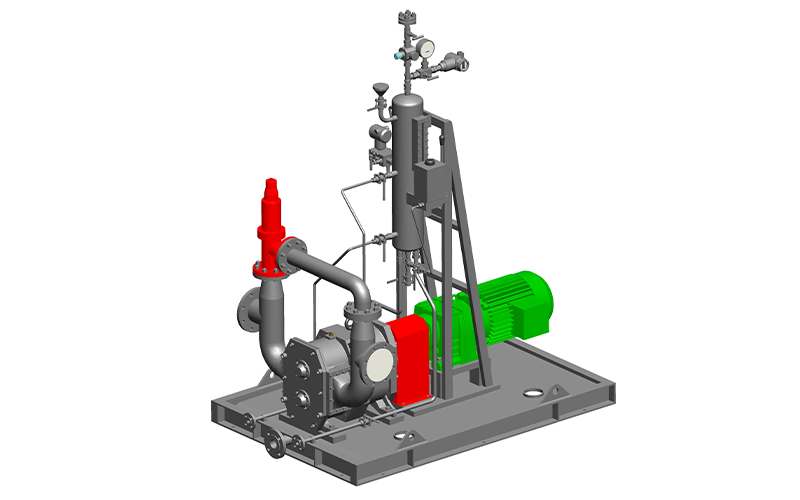

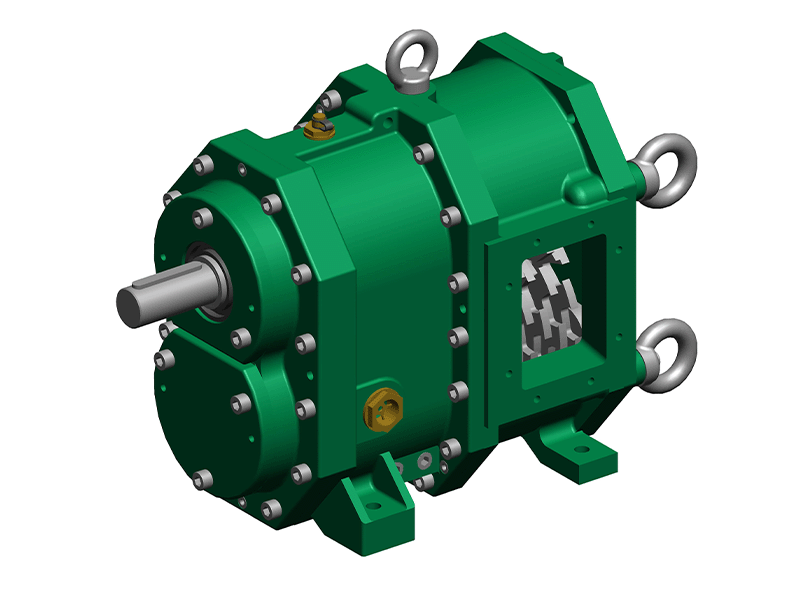

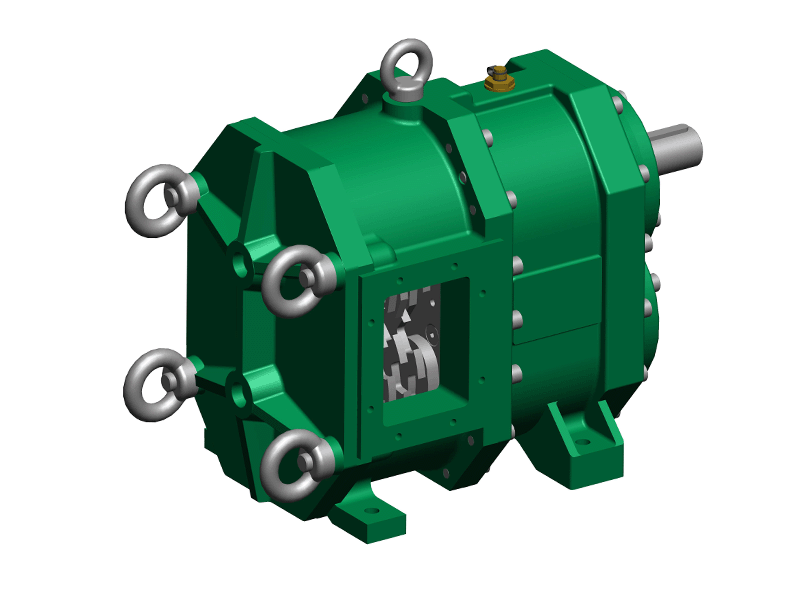

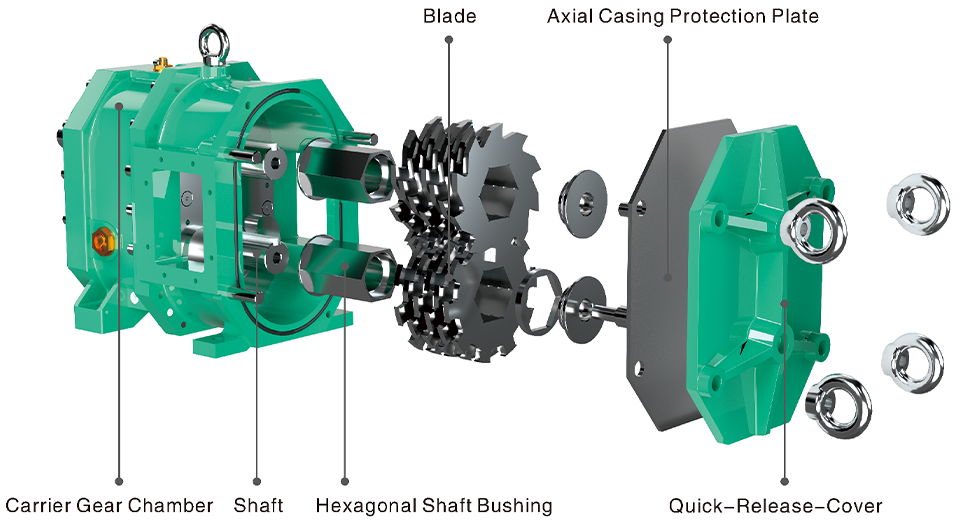

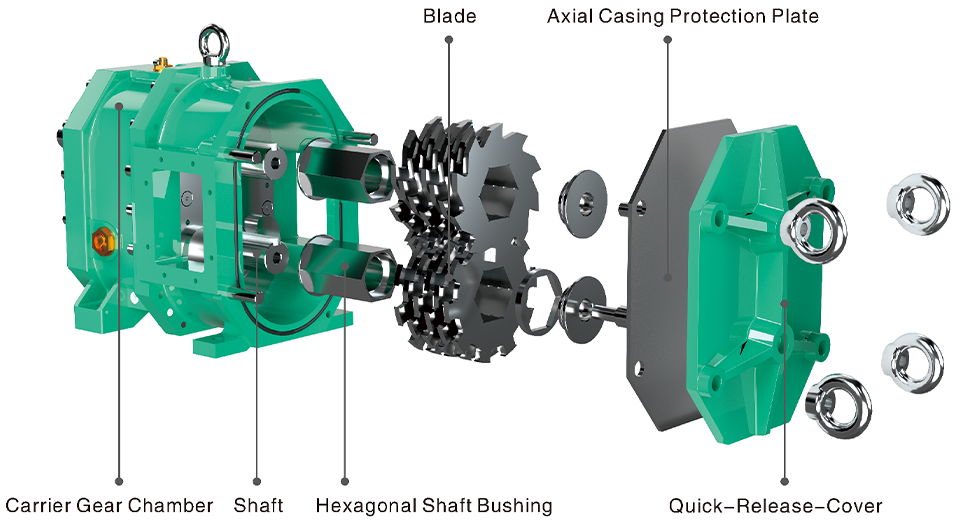

Structure and Composition

|

1. Quick-Release-Cover

Due to the strong Accuvon multicrusher shell and single-sided bearing design, the Accuvon multicrusher can also be inspected and replaced through the quick-opening end cover, allowing all components in the cavity to be inspected and replaced. This allows the Accuvon multicrusher to be repaired online as well.

The end cap can be removed by simply removing the four retaining screws, making repairs quick and easy. All current-carrying parts can be repaired and replaced without dismantling the pipeline or removing the equipment from the pipeline, and there is no need to lift or carry the equipment.

2. Axial Casing Protection Plate

Axial protective liners are installed as standard on the front and rear ends of the housing inner wall. The inspection and replacement of the axial lining plate can be carried out online through the quick-opening end cover.

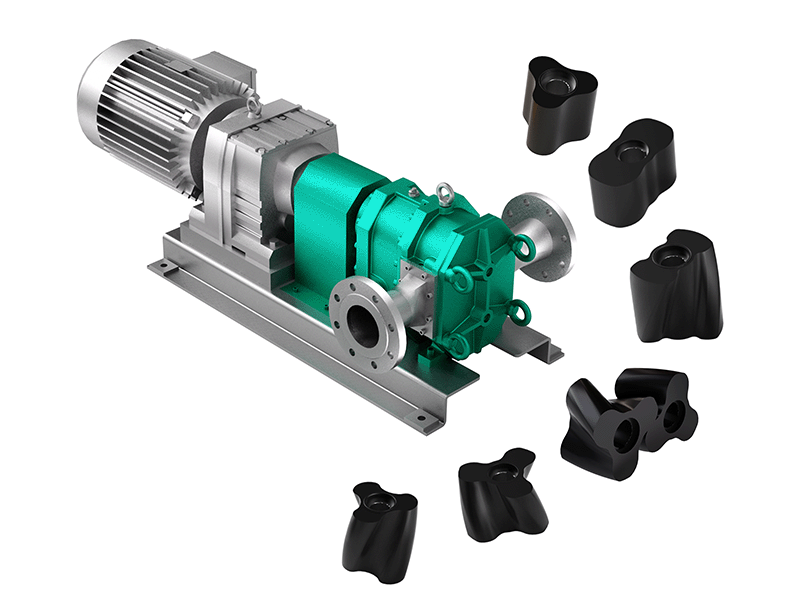

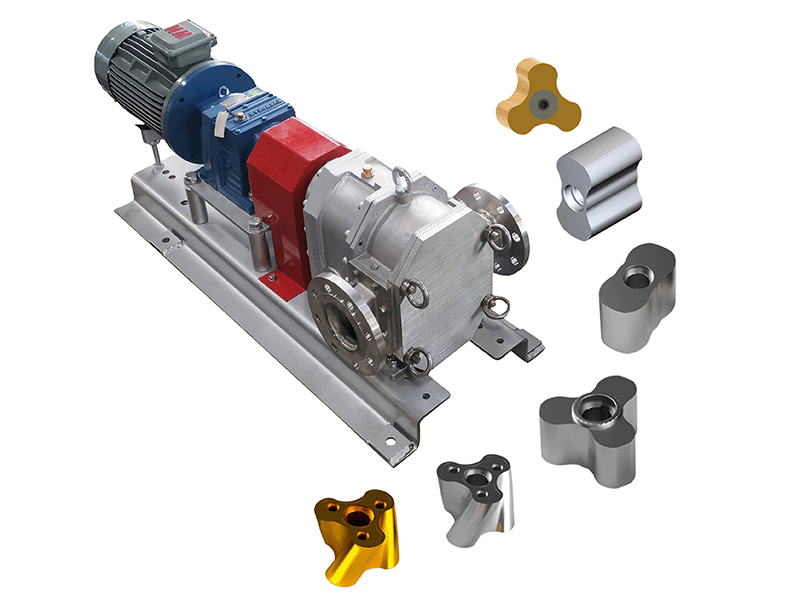

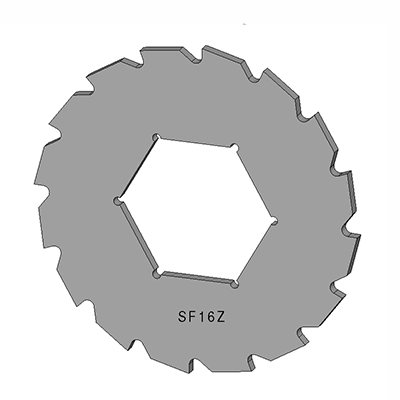

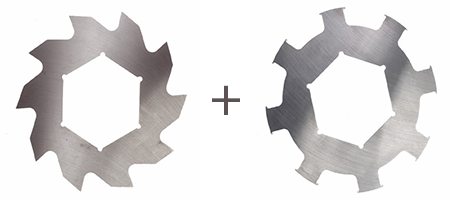

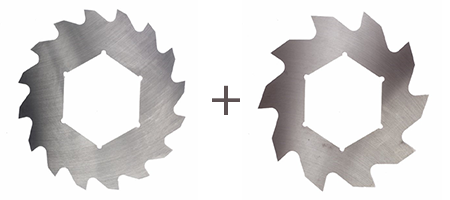

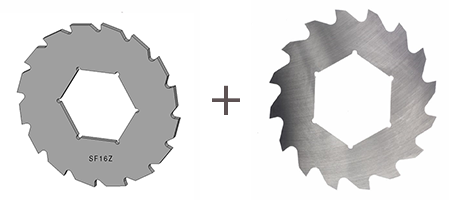

3. Blade & Blade Combination

The CNC machining cutting tool has high precision to achieve the best cutting effect. Meanwhile, the blade has various materials ,shapes and blade combinations for selection to meet the needs of various working conditions. Besides, blades of different shapes and numbers of teeth can be installed in each device, and the material of the cutting blade can be selected according to the chemical and physical characteristics of the medium.

Blade G10Z:ten-toothed - for cutting large solids;

Blade F16Z:16-toothed - can achieve a more thorough cutting effect, suitable for cutting fibers;

Blade SF16Z:a very fine 16-toothed blade, suitable for special cutting conditions;

Blade G8Z: uniform 8-toothed lade , can be used in conjunction with the above-mentioned tools to achieve a excellent cutting effect;

The blade G10Z and G8Z are used in combination to cut the raw materials for biogas production,and then transport them to the biogas tank for fermentation.

The combination of blade F16Z and G10Z is used for cutting meat and bone media in large slaughterhouses

The combination of blade SF16Z and F16Z is used to cut and crush solid materials of different sizes into uniform media.

Biaxial shearing design, reliable, powerful and durable, compact structure, small footprint, MIP maintenance (cutting parts can be quickly replaced), low energy consumption, no internal friction, easy to adjust cutting effect, no friction between parts , long service life, different types of blades are optional - different cutting effects, submersible models and various materials are available,low spare part cost, pressure-resistant design (up to 16bar)

4. Hexagonal Shaft Bushing

The hexagonal bushing is matched with the shaft on the inside of the bushing. It fixes the hexagonal bushing through a flat key and the shaft diameter. The hexagonal bushing on the outside is matched with the cutter and the limit isolation block. Secure the cutter and spacer block.

5. Shaft

The shaft, which is completely free from contact with the material, is equipped with a hexagonal adapter. The shaft is connected to a mechanical seal and separates wetted parts from non-wetted parts. This kind of mechanical seal is very durable. At the same time, when the mechanical seal needs to be replaced, you only need to open the cover of the machine, and the inspection and replacement work can be completed immediately.

6. Carrier Gear Chamber

The synchronizing gears are housed in a separate, sealed gearbox. High-quality and strong gears and shafts that are not in contact with the material together ensure precise transmission and a long service life of the machine. Gears of different diameters result in corresponding rotational speeds of the blade/cutter structure to achieve the best shearing results.

| Model |

Flow(max)

m³/h |

Flow speed

m/s |

Flange diameter

Standard(mm) |

Flange diameter

Optional(mm) |

Power

Standard(Kw) |

Power

Optional(Kw) |

| HAP80 |

25 |

3 |

DN80 |

DN100,DN125,DN150 |

3 |

4 |

| HAP100 |

40 |

3 |

DN100 |

DN125,DN150,DN200 |

3 |

4 |

| HAP120 |

60 |

3 |

DN100 |

DN125,DN150,DN200 |

3 |

4 / 5.5 |

| HAP140 |

80 |

3 |

DN125 |

DN150,DN200 |

4 |

5.5 |

| HAF125 |

100 |

3.1 |

DN125 |

DN150,DN200 |

7.5 |

11 |

| HAF150 |

150 |

3.1 |

DN150 |

DN200,DN250 |

11 |

|

| HAF200 |

200 |

3.1 |

DN200 |

DN250 |

11 |

|

| HAX250 |

300 |

2.4 |

DN250 |

DN300,DN350 |

18.5 |

|

| HAX300 |

500 |

2.4 |

DN300 |

DN350,DN400 |

18.5 |

|

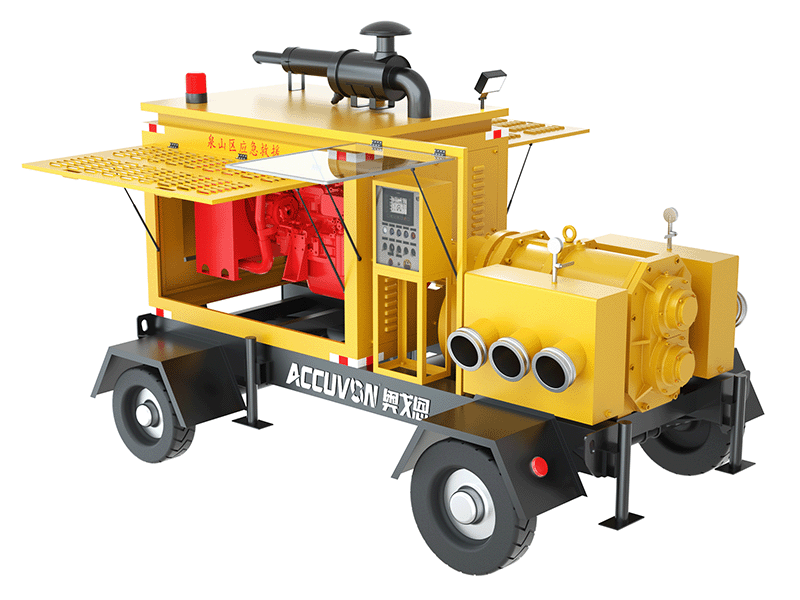

Optional Materials, Control System

|

Optional blade material

The standard material of the cutter is German standard hardened alloy steel 1.7218, also German standard alloy tool steel 1.2379 is available.

Control System

The Accuvon grinder can optionally be equipped with an Accuvon Control Unit, the application of intelligent reverse control can prolong the service life of the blades, and also help to solve any clogging problems.

Reverse Start

After the reverse function of the grinder is started, it will rotate for 5 seconds. After the end, it will switch back to the original direction of rotation;

Blocking

Reverse control is activated. When it reaches 70% of the rated capacity of the motor, the reverse function starts (this value can be set through the control unit) ;

Error Message

For example, the fifth consecutive reverse occurs within 10 minutes due to over capacity;

Reverse Counting

The counter runs in the background, recording the number of inversions associated with the load;