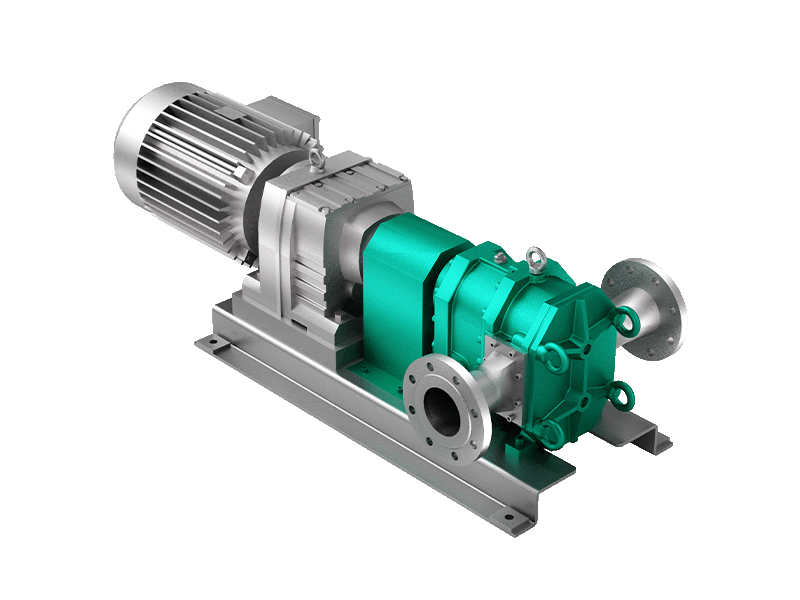

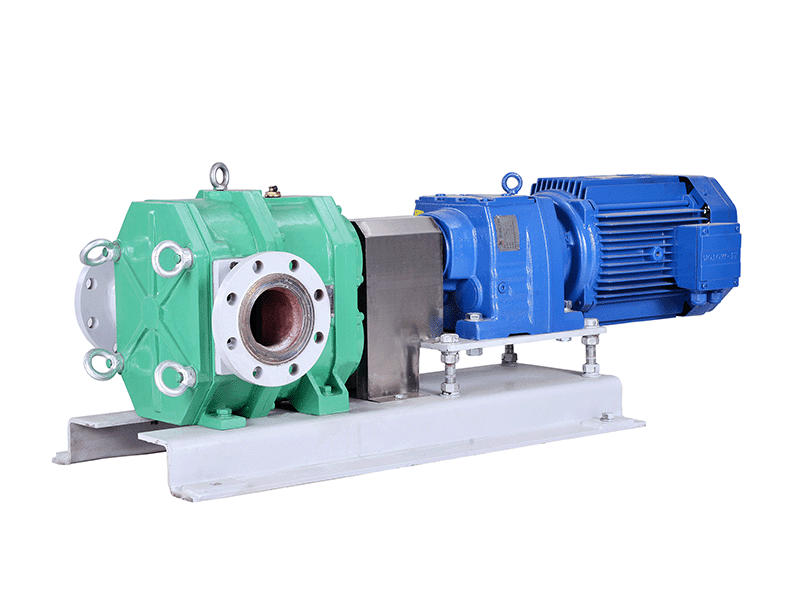

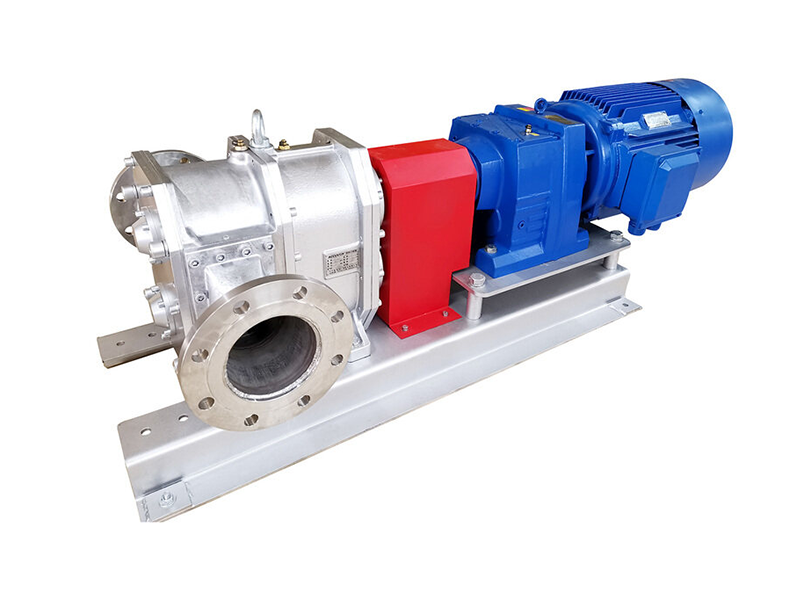

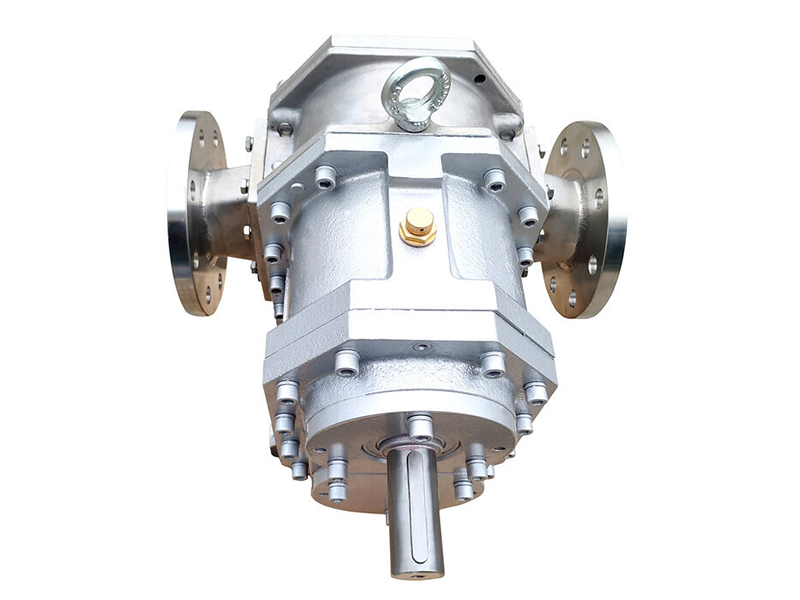

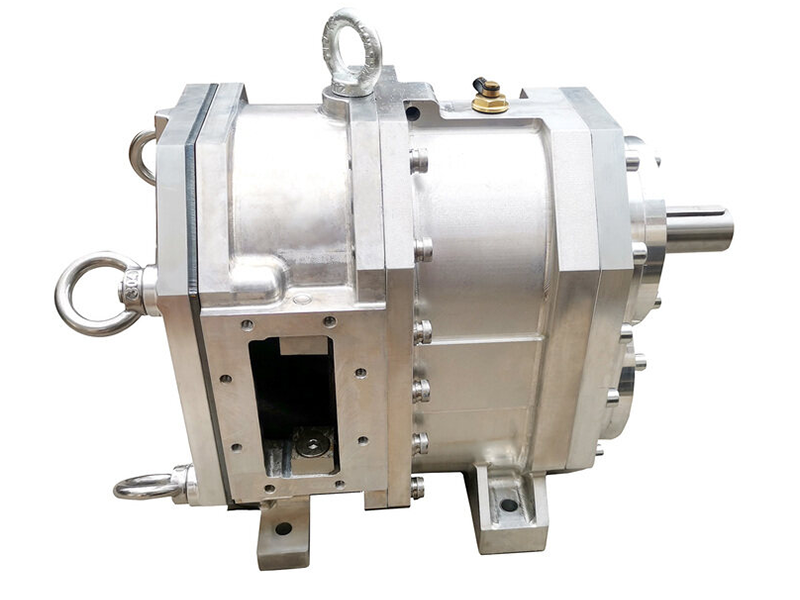

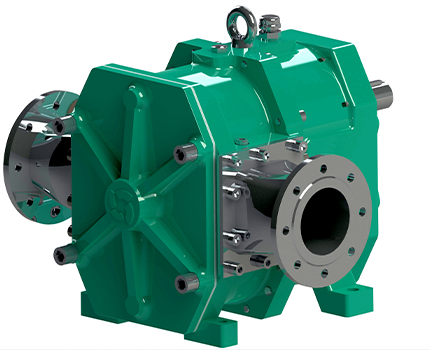

Sanitary rotary lobe pump play a vital role in maintaining product quality, ensuring hygiene and meeting regulatory requirements in the sanitary processing industry. They are critical for conveying liquid and viscous products while maintaining cleanliness and product integrity throughout the process. Here are some of the main features and characteristics of sanitary rotary lobe pump:

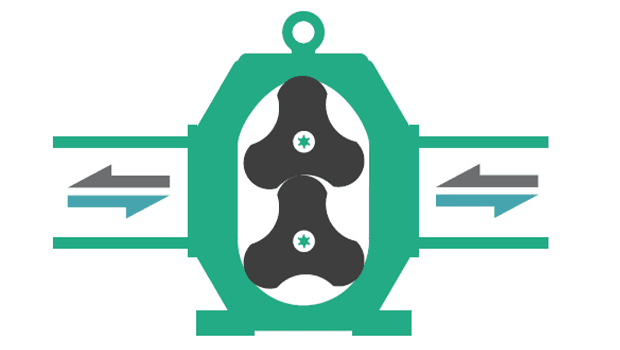

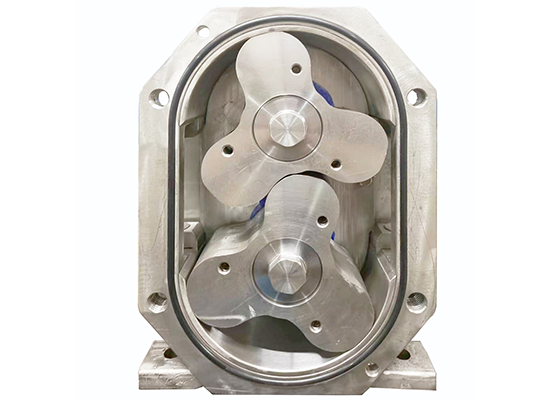

- 1. Positive Displacement: Like other positive displacement pumps, sanitary rotor pumps work by trapping fluid in a rotating part (the rotor)

- and the pump casing (stator), thereby creating discrete volumes of fluid that flow through the pump. This design provides precise metering and consistent flow, making it suitable for applications requiring precise metering or handling of viscous fluids.

- 2. Hygienic design: Hygienic cam pumps are constructed using materials and designs that meet strict hygiene standards. They are usually made of stainless steel

- or other FDA-approved materials. They feature smooth surfaces, polished interiors and minimal gaps to prevent product contamination and are easy to clean and disinfect.

- 3. Gentle handling: These pumps offer gentle product handling, making them suitable for conveying delicate or shear-sensitive fluids without,Damage the integrity or consistency of the product. This feature is particularly important in industries where product quality is critical, such as food and pharmaceutical manufacturing.

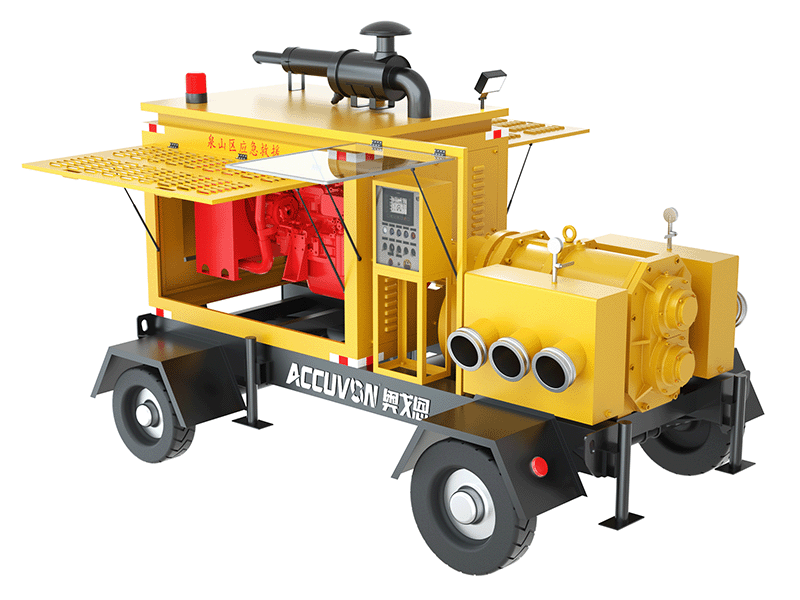

- 4. Self-priming: Many sanitary rotary lobe pumps are self-priming, which means they can bleed air from the suction line and create a vacuum to draw product in, making them suitable for applications that require a stable flow rate, even when handling viscous or non-Newtonian This also ensures reliable operation and prevents cavitation when using fluids.

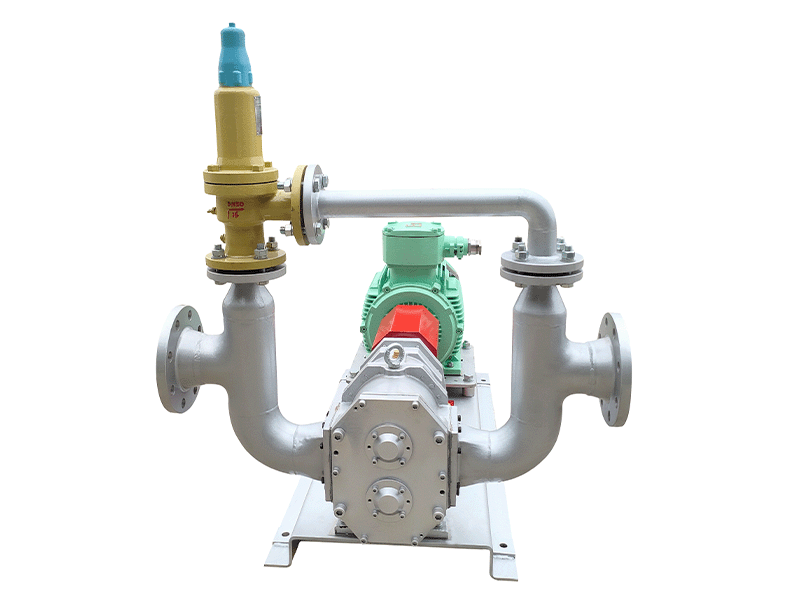

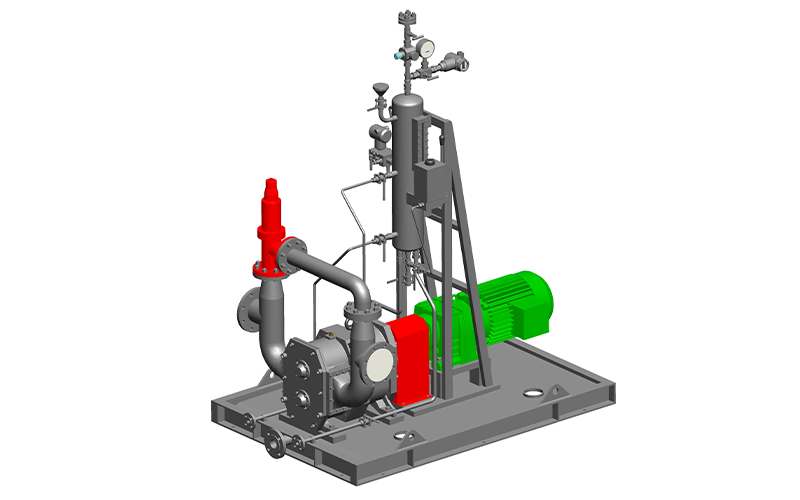

- 5. Clean in Place (CIP) Function: These pumps are designed for easy cleaning and sanitation using a Clean in Place (CIP) system. They feature quick-disconnect components, hygienic seals and hygienic connections to help with thorough cleaning and sterilization, minimizing downtime and ensuring product purity.

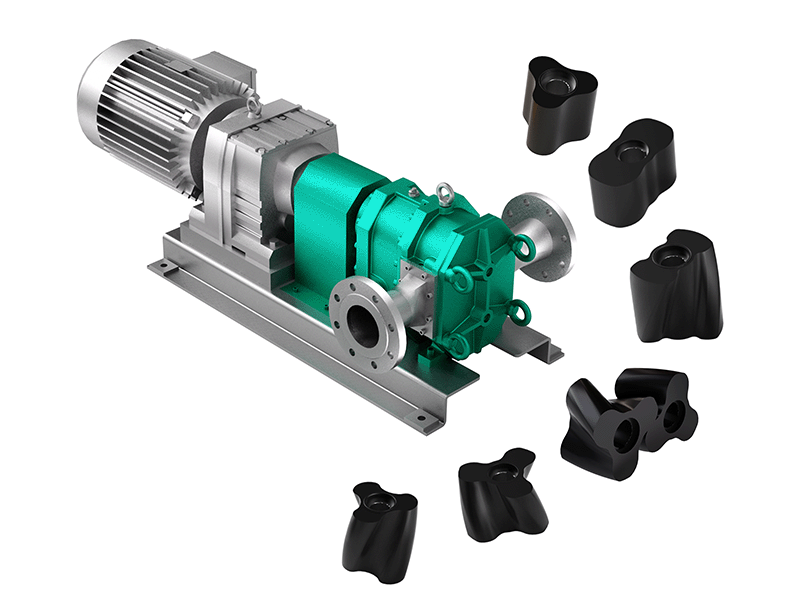

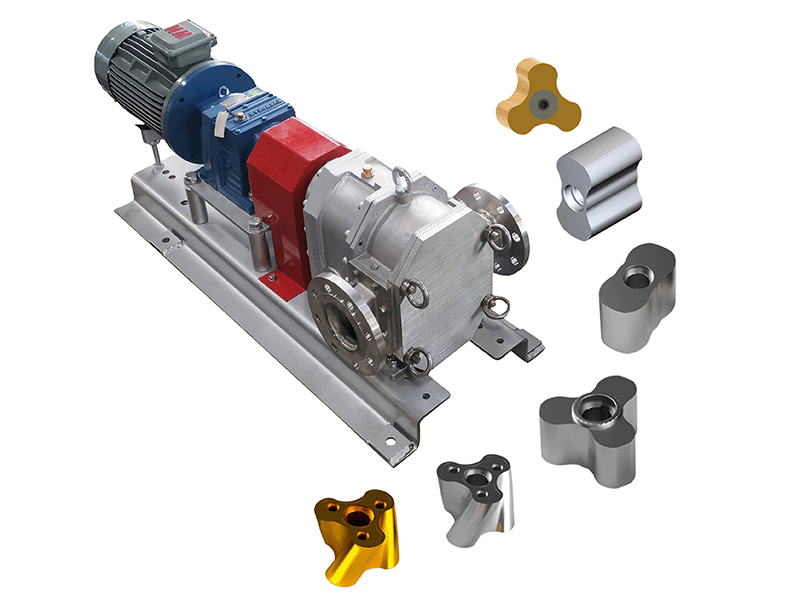

- 6. Versatility: sanitary rotary lobe pumps can handle a variety of viscosities, from thin liquids to high-viscosity fluids, and even products containing solids or particles. They are suitable for conveying liquids, creams, gels, suspensions and emulsions, making them a versatile solution for a variety of process applications.

- 7. High Efficiency: These pumps have high volumetric efficiency, maintaining consistent flow rates even when handling challenging fluids or operating under changing conditions.

- 8. Compliance: Sanitary rotary lobe pumps typically comply with industry standards and regulations such as 3-A Sanitary Standards, EHEDG (European Hygienic Engineering and Design Group), FDA (Food and Drug Administration), and cGMP (Current Good Manufacturing Practice) Manufacturing Practices) Guide.

Sanitary rotor pumps offer many advantages in the food and hygiene industries, making them ideal for liquid transfer and handling. Here are some of the main advantages of sanitary rotor pumps:

- 1. Hygiene: The design of the sanitary rotor pump complies with strict hygiene standards and is made of food-grade materials. The surface is smooth and easy to clean, avoiding the risk of bacterial growth and contamination, and ensuring the hygiene and safety of the product.

- 2. Adaptability: sanitary rotor pumps can handle various types of liquids, including media with different properties such as high viscosity, high temperature, particles, and perishables, and are suitable for a variety of media processing techniques and processes.

- 3. Gentleness: These pumps are able to handle media gently, maintaining the original texture, taste and nutritional value of the product, avoiding the possibility of over-mixing or damaging the food.

- 4. Accuracy: Sanitary rotor pumps are positive displacement pumps that can provide precise flow control and shear force, and are suitable for production processes that require precise batching and processing, such as pharmaceuticals, food, etc.

- 5. Reliability: These pumps usually have stable and reliable performance and can operate stably for a long time without damage or leakage, ensuring the stability and reliability of the production process.

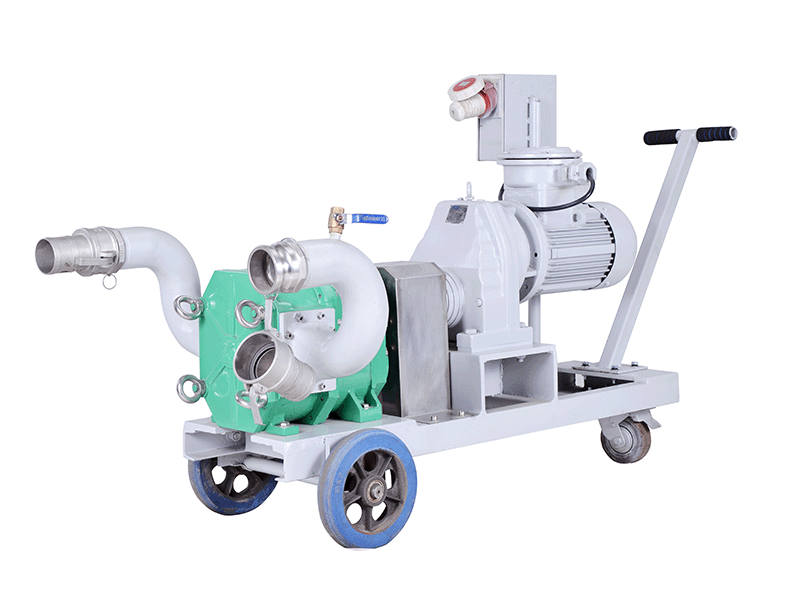

- 6. Easy to clean: Sanitary rotor pumps are simple in design, easy to disassemble and clean, and usually have a structure without dead ends, which facilitates thorough cleaning and disinfection, reducing maintenance costs and downtime.

- 7. Energy-saving and efficient: These pumps usually have efficient energy utilization, which can reduce energy consumption and production costs and improve production efficiency.

To sum up, the sanitary rotor pump has the advantages of precision, gentleness, reliability, easy cleaning, energy saving and high efficiency in industries that require high hygiene standards, and is an ideal choice for liquid transportation and processing.

Sanitary rotor pumps have a wide range of applications in industries that require high hygiene standards, mainly including the following aspects:

- 1. Food processing: In the food industry, sanitary rotor pumps are often used for raw material transportation, process liquid circulation, and

- Mixing and ingredients. They are suitable for use in a variety of food production processes, including the production of beverages, jams, condiments, sauces, dairy products, etc.

- 2. Dairy processing: In the dairy industry, food rotor pumps are used to transport milk, yogurt, cream, milk powder, whey and other milk

- Product raw materials or finished products. They handle dairy products gently, maintaining product texture and mouthfeel, and are suitable for dairy processing and delivery.

- 3. Candy and chocolate manufacturing: In the candy and chocolate manufacturing industry, food rotor pumps are usually used to transport chocolate syrup, syrup, jam, cream and other raw materials. They are able to deliver high-viscosity syrups and slurries stably, ensuring uniform mixing and high quality of the product.

- 4. Condiment and oil processing: Food rotor pumps are also widely used in the condiment and oil processing industry, such as the production of tomato sauce, salad dressing, olive oil, edible oil, etc. They can reliably deliver high concentrations of seasonings and oils, maintaining product taste and flavor.

- 5. Frozen food processing: In the frozen food processing industry, food rotor pumps are used to transport frozen food slurry, ice cream base, jelly, sorbet and other liquid raw materials. They can stably transport high-concentration frozen food slurry in low-temperature environments and are suitable for various frozen food production processes.

- 6. Beverage industry: In the beverage industry, sanitary rotor pumps are widely used to transport liquid raw materials or finished products such as juice, soda, beverage base, concentrated juice, alcoholic beverages, etc. They can stably transport high-concentration syrups, juice concentrates and particle suspensions and are suitable for various beverage production processes.

- 7. Cosmetics manufacturing: In the cosmetics manufacturing industry, sanitary rotor pumps are usually used to transport cosmetic raw materials, lotions, flavors, pigments and other ingredients. These pumps ensure the texture and stability of cosmetics and meet the hygiene requirements of cosmetics manufacturing.

- 8. Pharmaceutical industry: In the pharmaceutical industry, sanitary rotor pumps are widely used in the transportation of pharmaceutical raw materials, mixing, filling and packaging of pharmaceutical preparations. These pumps ensure the hygiene and safety of the pharmaceutical production process and meet the strict requirements of pharmaceutical production.

- 9. Biotechnology: In the fields of biotechnology and bio pharmaceuticals, sanitary rotor pumps are often used for the transportation and processing of biological products, such as cell culture media, culture fluids, bacterial suspensions, etc. They enable the stable delivery of biologics, maintaining their activity and purity.

Based on the above application scenarios, common transmission media of sanitary rotor pumps include:

- 1. Juice: including orange juice, apple juice, grape juice, juice concentrate and other fruit juices.

- 2. Berry pulp: such as strawberry jam, blueberry jam, raspberry jam, etc.

- 3. Sauces: including tomato sauce, chili sauce, garlic sauce and other seasoning sauces.

- 4. Alcoholic beverages: including beer, wine, spirits and other alcoholic beverages.

- 5. Dairy products: including milk, yogurt, cream, milk powder and other dairy products.

- 6. Condiments and condiments: such as flavors, spices, pigments, etc.

- 7. Grease: Including edible oil, vegetable oil, animal oil and other various greases.

- 8. Syrup and honey: including glucose syrup, fructose syrup, honey and other sweeteners.

- 9. Mixture of yogurt and jam: For example, a mixture used to make yogurt jam drinks.

- 10. Other food raw materials: such as suspended particles, suspensions, suspended slurries, etc.

- 11. Cosmetic raw materials: including various cosmetic raw materials, such as lotions, flavors, pigments, etc.

- 12. Pharmaceutical raw materials: including various pharmaceutical raw materials commonly used in the pharmaceutical industry, such as medicinal liquids, medicinal slurries, medicinal liquid suspensions, etc.

- 13. Pharmaceutical preparations: including various pharmaceutical preparations, such as oral liquids, oral capsules, injections, etc.

- 14. Biological products: including biological products commonly used in the fields of biotechnology and bio pharmaceuticals, such as cell culture media, culture fluids, bacterial suspensions, etc.

These media usually have different characteristics such as viscosity, concentration, particle size and pH value. The sanitary rotary pump can adapt to these different media, transport and process stably, and ensure the quality and stability of the product.