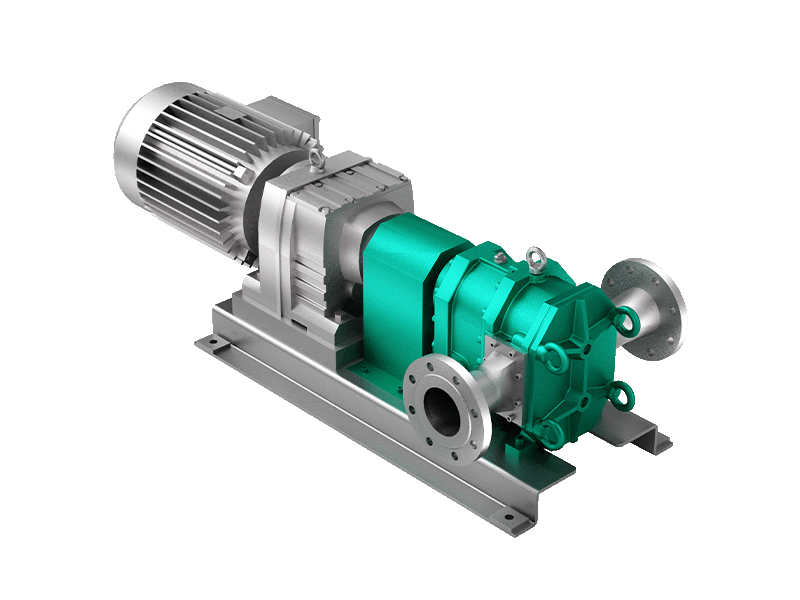

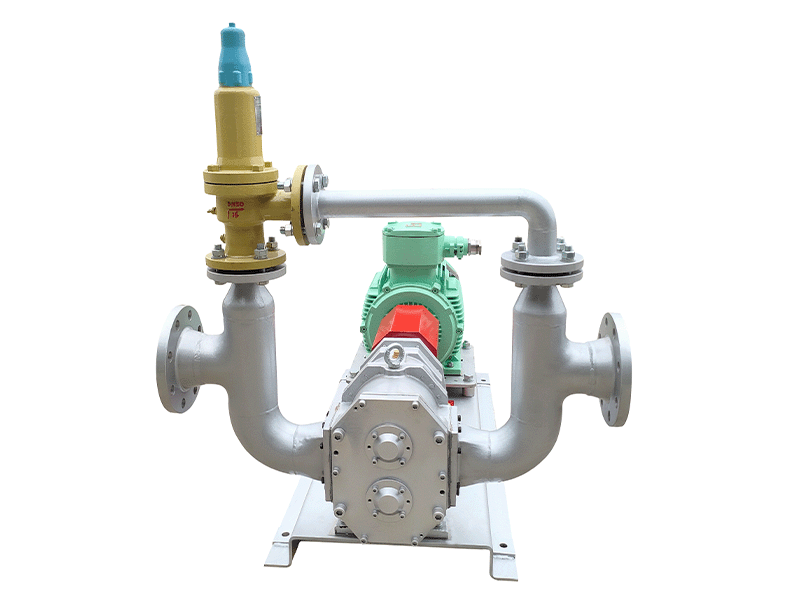

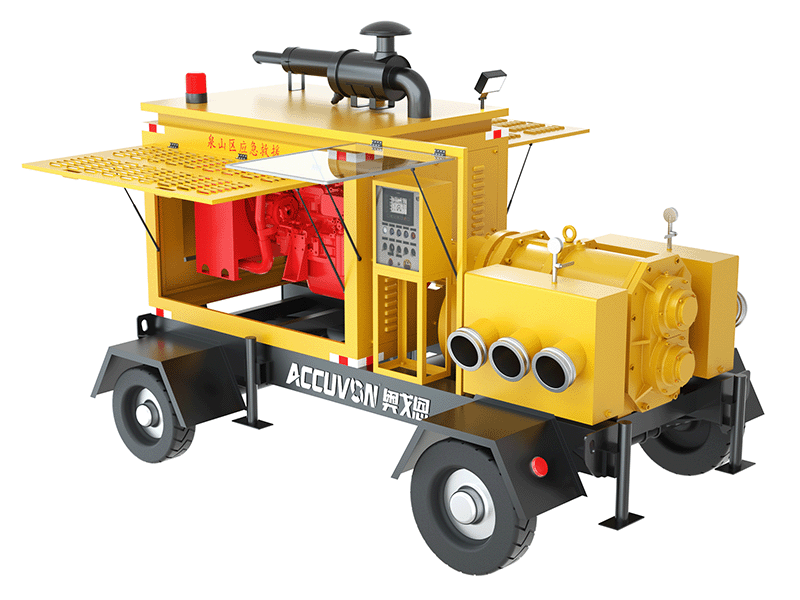

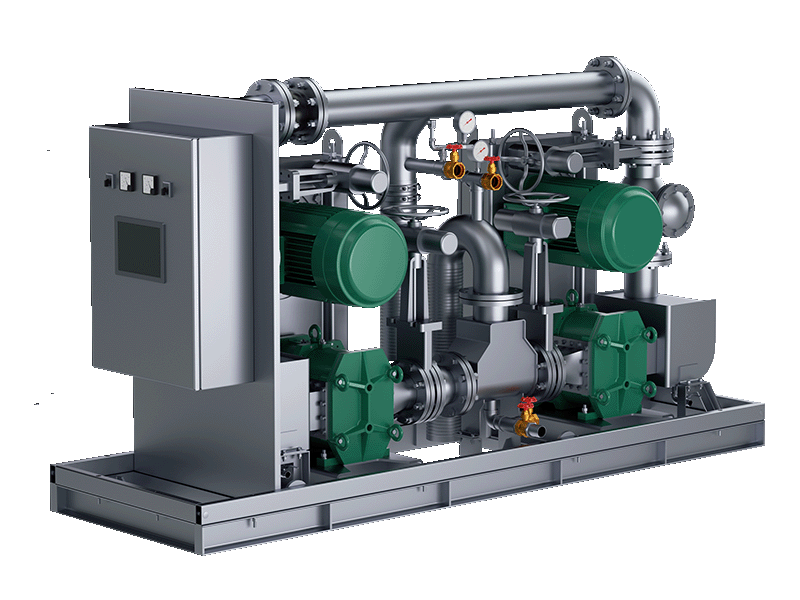

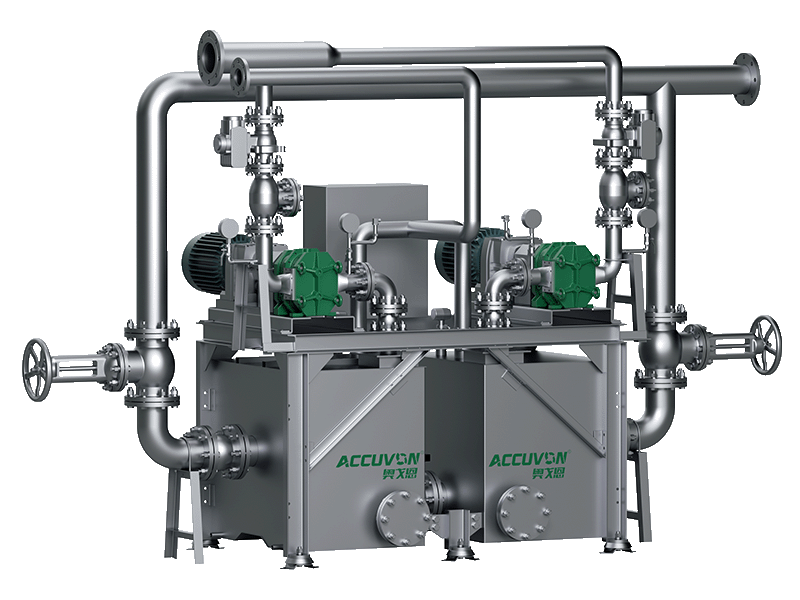

With the wide range of 14 pump sizes, a large selection of equipment and additional parts, Accuvon is able to build rotary lobe pumps which are perfectly suited for every single tanker truck. Liquid as well as viscous or abrasive pumped media can be conveyed easily. Even solids and chemically aggressive media do not pose a problem.

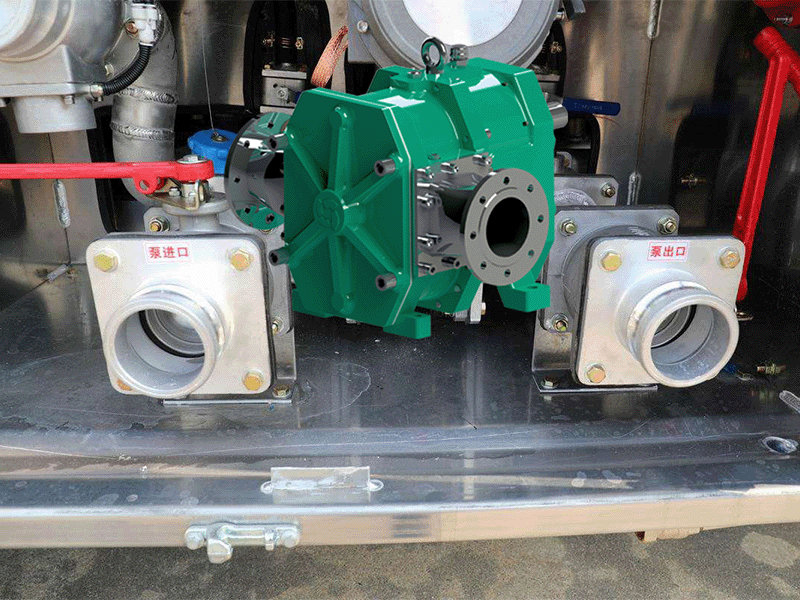

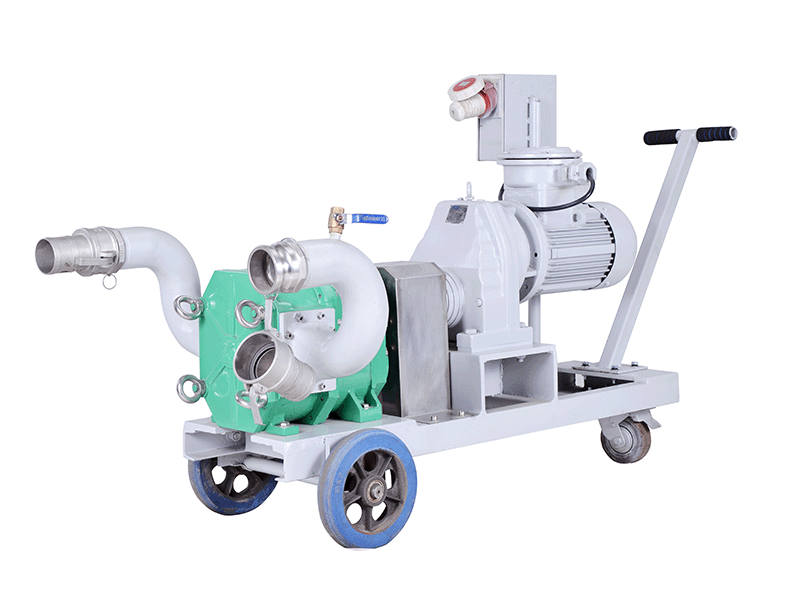

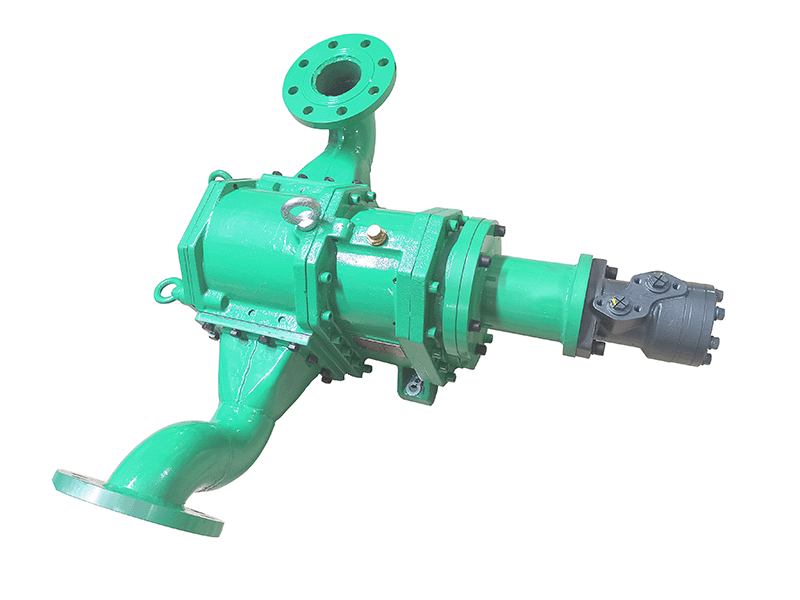

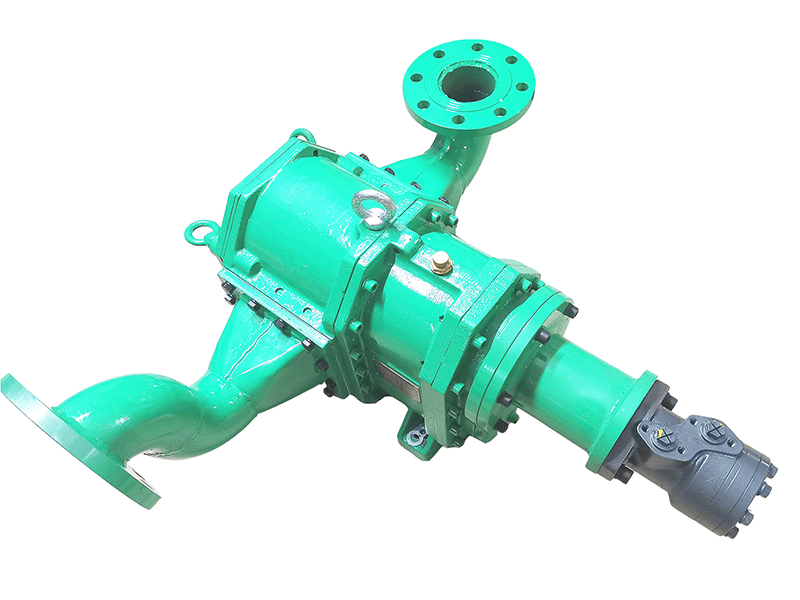

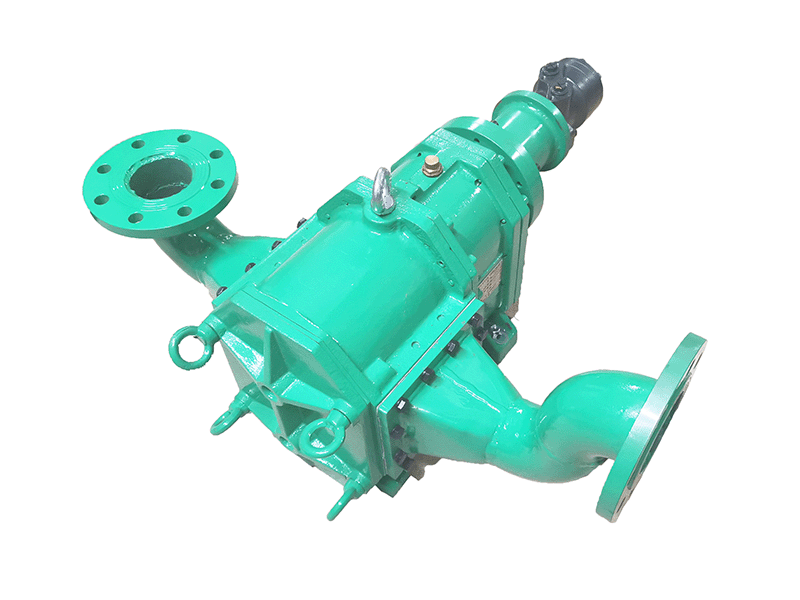

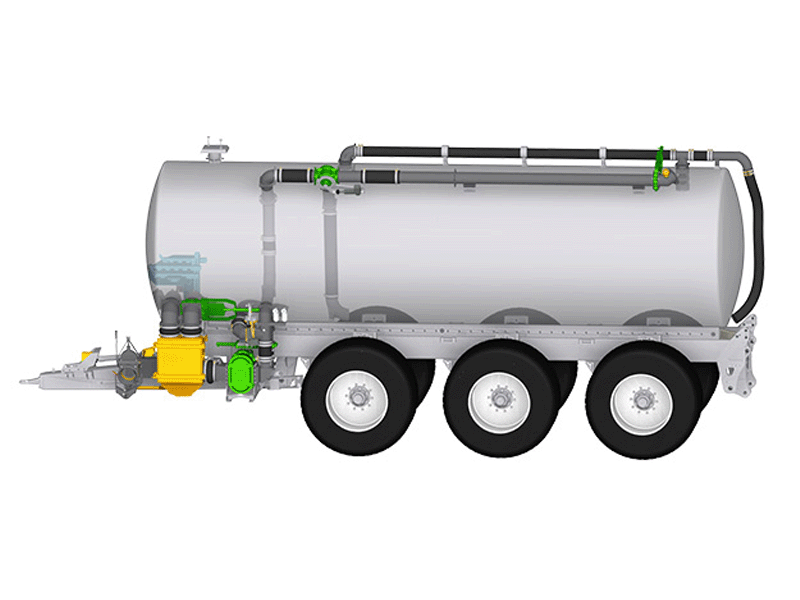

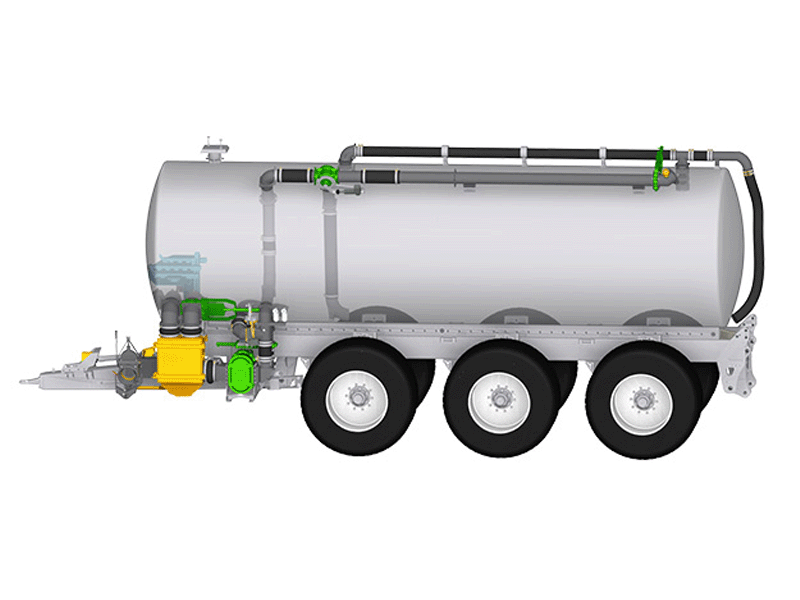

For years, Accuvon rotary lobe pumps have been used successfullyas tanker truck pumps.In particular the high quality, the compactand low-on-space design and the option of reversing the pump are the reason why the Accuvon pump is the ideal tanker truckpump.

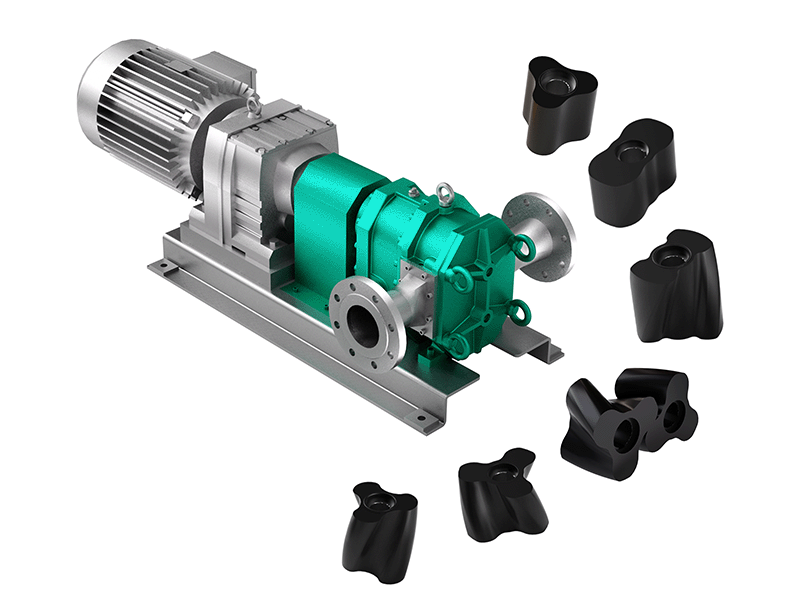

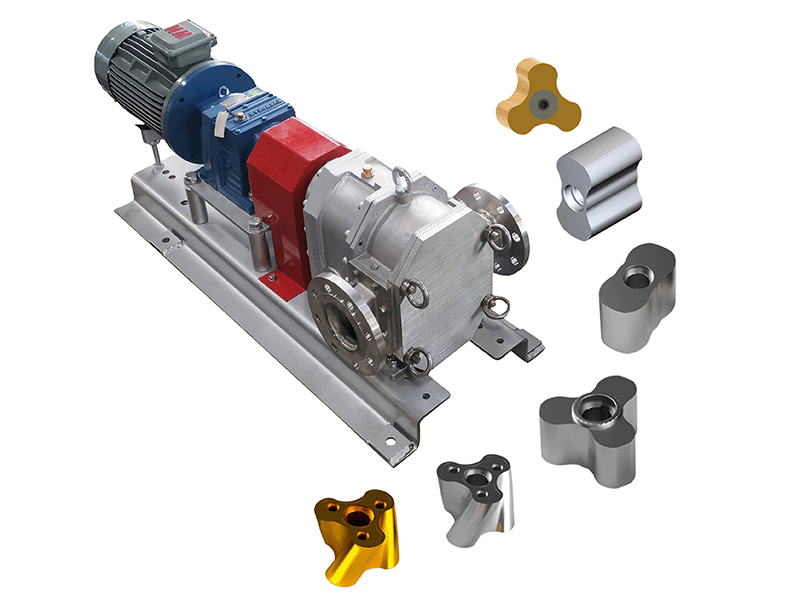

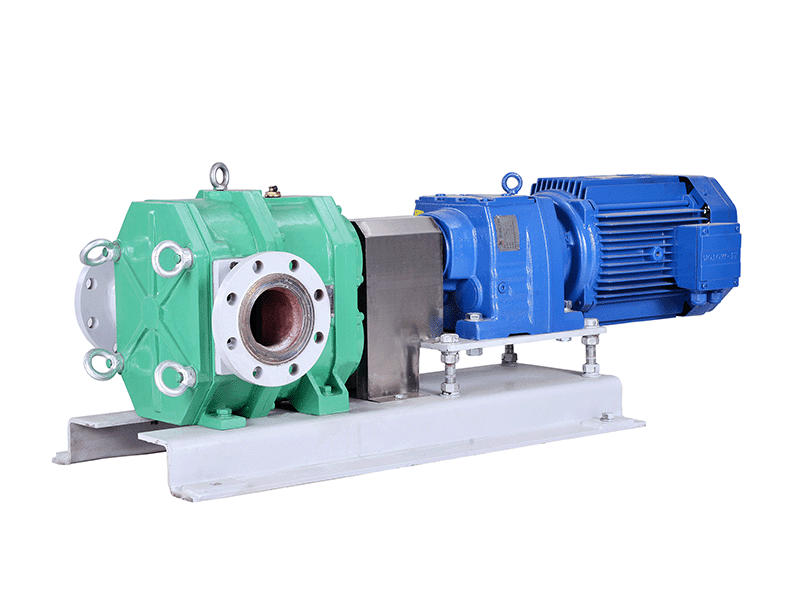

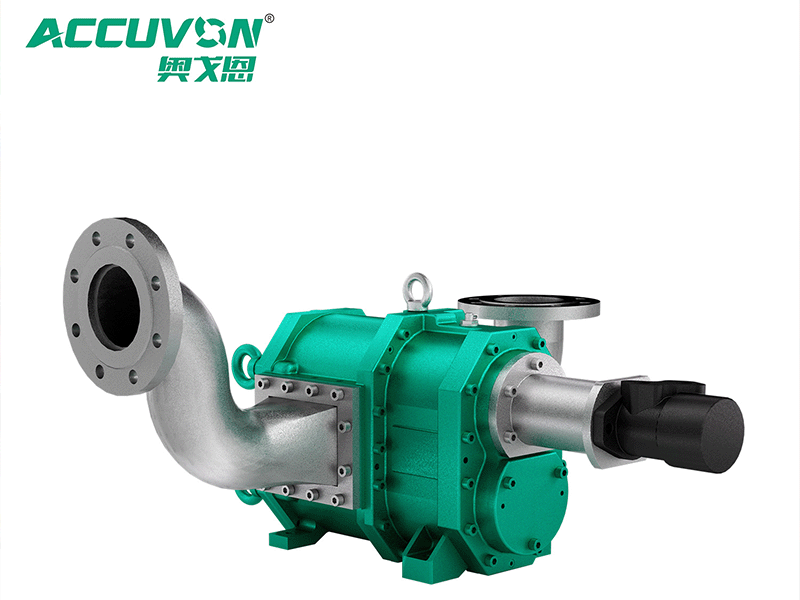

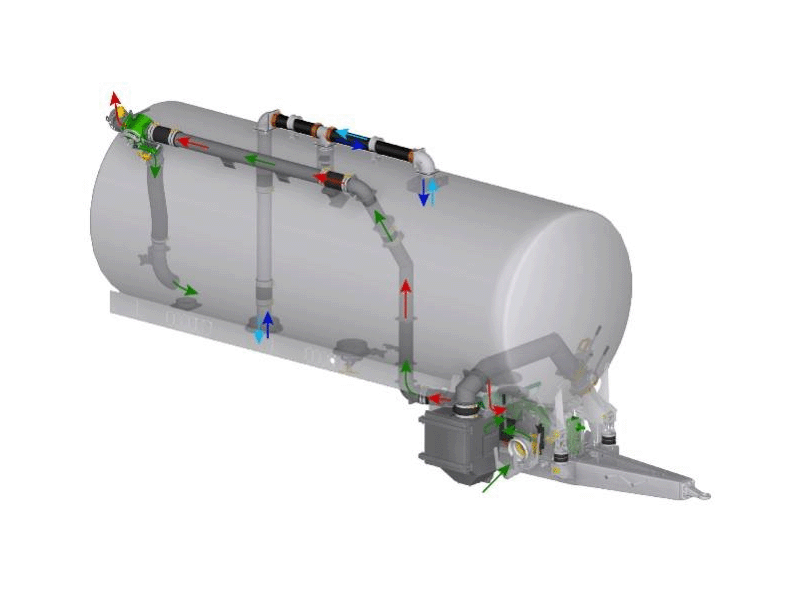

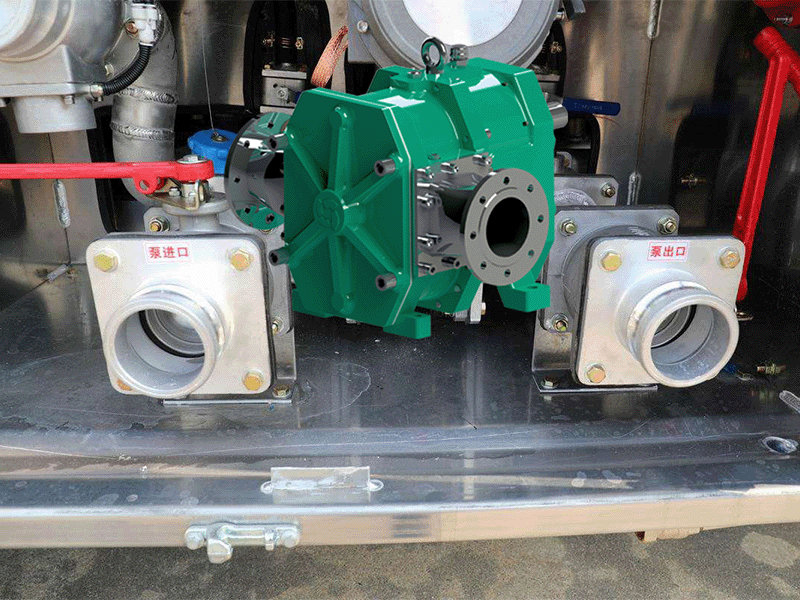

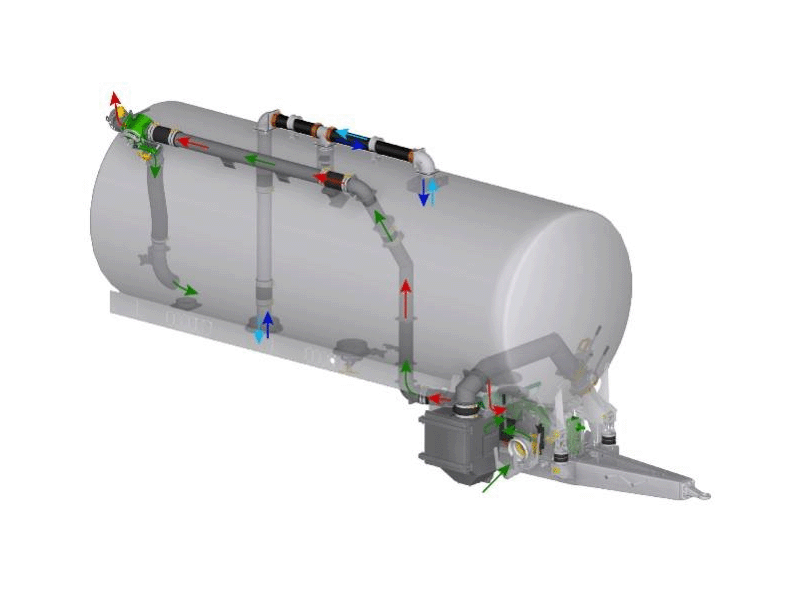

The lobe system uses the mechanical action of two lobe rotors. Their rotation creates a vacuum on the suction side, which attracts the slurry into the pump body. The slurry is then carried through the lobes, along the rotor wall and discharged on the other side. These pumps do not take much place although they have a relatively high capacity. Their suction principle ensures them a maximum stability and eliminates almost all vibrations. Furthermore, they are all equipped as standard with an automatic stop system (optional on TETRALINER) and wear rings. These pumps have many advantages: high filling and emptying speed, possibility of pumping thicker slurry than with vacuum pumps, compatibility with long suction hoses or spreading implements, pumping performance maintained at a depth of more than 3.5 m, standard equipment for mixing and transfer from pit to pit, output pressure higher than 1 bar guaranteeing a good distribution with a high working width, etc.

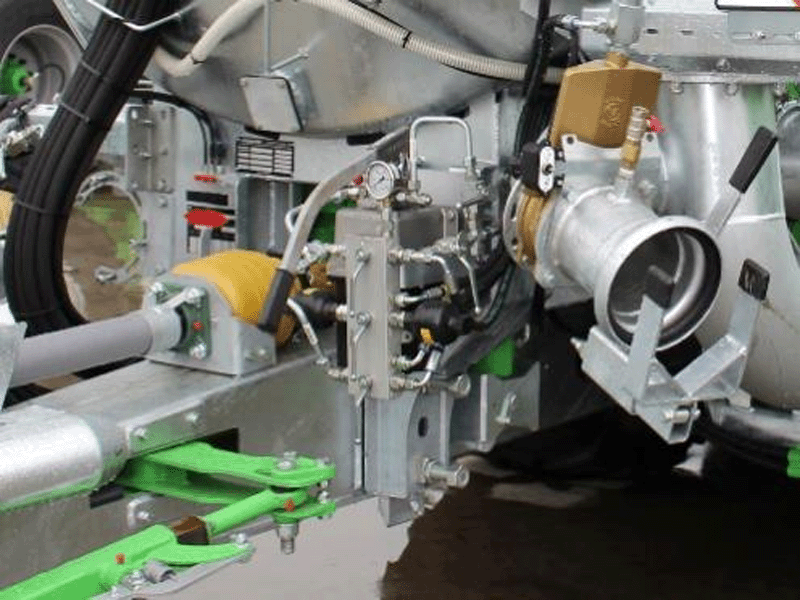

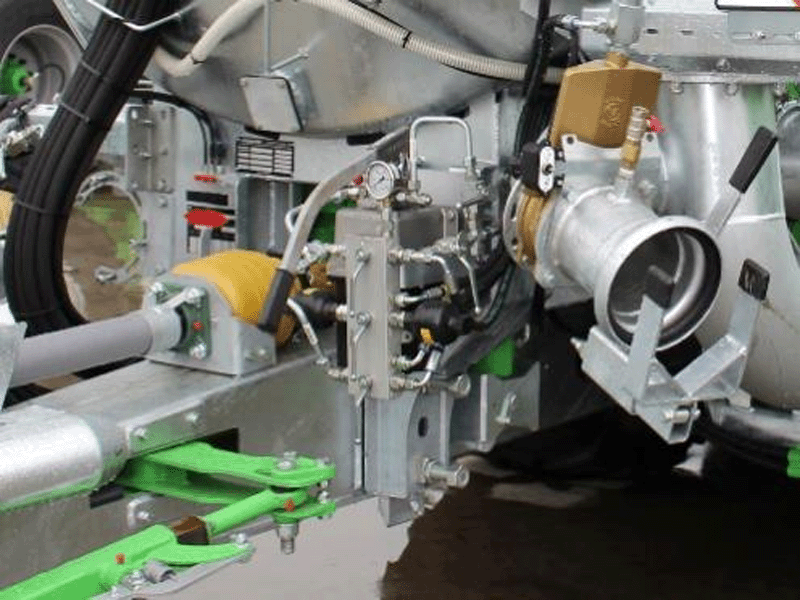

The Accuvon lobe pumps offered by tank truck manufacturer are all equipped with Three-blade spiral wide-edge optimized type lobes that guarantee a perfectly linear flow. This means that they are not subject to vibration, thereby extending the lifespan of the moving parts. This unique design limits cavitation, allows higher rotation speeds, and therefore higher flow rates, for the same pump size. Lobe wear and turbulence at the inlet are greatly reduced. Tank truck manufacturer fits the lobe pumps on the side of the tankers so that they are easily accessible for maintenance. This assembly includes a PTO drive and an angle transmission gearbox. As an option, the drive can also be powered by a hydraulic motor, for an easier and more precise adjustment of the flow rate.

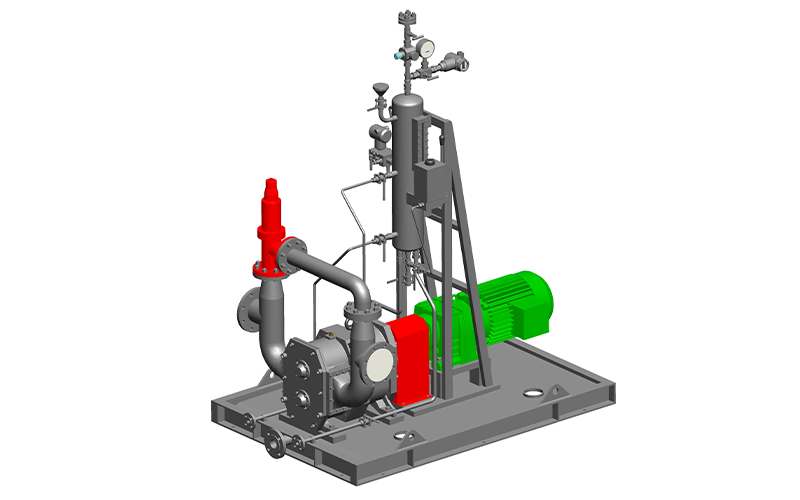

In order to protect the volumetric pump as much as possible against foreign bodies or to avoid blockages due to heavy slurry, Tank truck manufacturer has developed the "Rotation-Cut" chopper. It is placed before the pump inlet to filter the slurry. This large-volume chopper is equipped with a drain valve: when you arrive at the field, you can open it from the driver's seat to remove any foreign bodies (stones, etc.) it could contain.

Unlike vacuum pumps, the slurry goes through the volumetric pumps and the flow rate mentioned here is the amount of liquid per minute. When used on slurry tankers, there could theoretically be an overflow. In order to avoid such a situation, an automatic filling stop system can be fitted. In this case, a signal from the float gauge gives the filling status and changes the position of the valves from "full" to "mixing in closed circuit". The pump then no longer sucks in slurry and does a mixing job.

+ Self-priming, pumping in slurp operation

+ Reversible pumping

+ Short-term dry-run capability

+ Compact, space saving design

+ Quick filling and emptying

+ Explosion proof compliant

+ Chemically resistant

+ Resistant to solids

+ 14 pump sizes with flow rates of up to 3,200 m³/h

+ Gentle pumping of shear-sensitive media

+ Ease of maintenance

A tank truck pump is a device used to pump liquid from a tank truck and deliver it to its destination. It has a wide range of applications. Here are some of the main application areas:

- 1. Chemical industry: In the chemical industry, tank truck pumps are often used to transport various chemical products, such as acids, alkalis, solvents, coatings, fertilizers, etc. These products need to be moved safely and efficiently to the production line or storage facility.

- 2. Food and beverage industry: In the food and beverage industry, tank truck pumps are used to transport liquid food raw materials, such as juice, milk, alcoholic beverages, etc., as well as finished products, such as beverages, oils, etc.

- 3. Oil and Gas Industry: In the oil and gas industry, tank truck pumps are commonly used to transport crude oil, petroleum products, natural gas liquids, liquefied natural gas (LNG), etc., as well as for chemical processing, refining or transshipment.

- 4. Sewage treatment: In the field of sewage treatment, tanker pumps can be used to clean sewage collection tanks, septic tanks, sewage treatment plants, etc., and transport sewage to treatment equipment or treatment sites.

- 5. Environmental protection: In the field of environmental protection, tanker pumps can be used to handle and transport toxic waste, hazardous chemicals, contaminated soil, etc.

- 6. Agriculture: In the agricultural field, tanker pumps are usually used to transport pesticides, fertilizers, irrigation water, etc.

Overall, tank truck pumps play an important role in many industrial and commercial sectors for the safe and efficient transfer of a variety of liquid substances. Its application range covers many fields from chemical industry to food, from petroleum to construction, etc., and plays an important role in ensuring production operations.