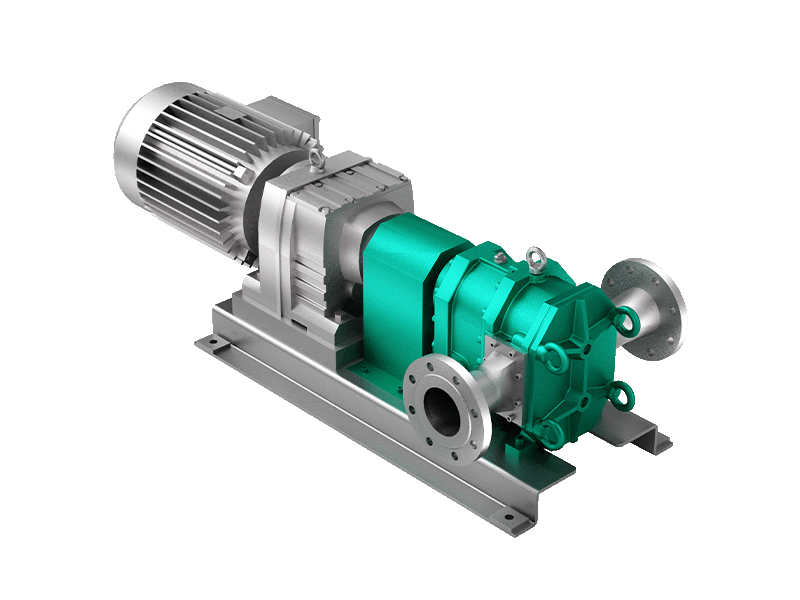

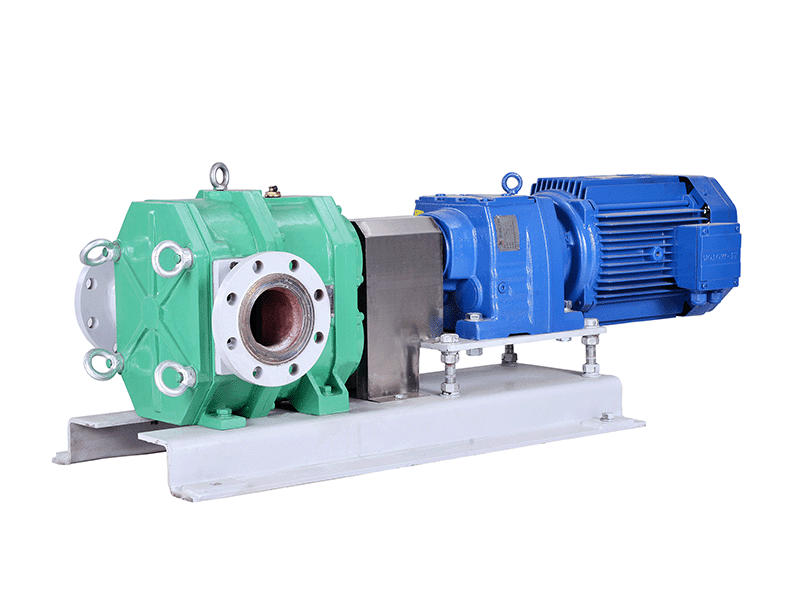

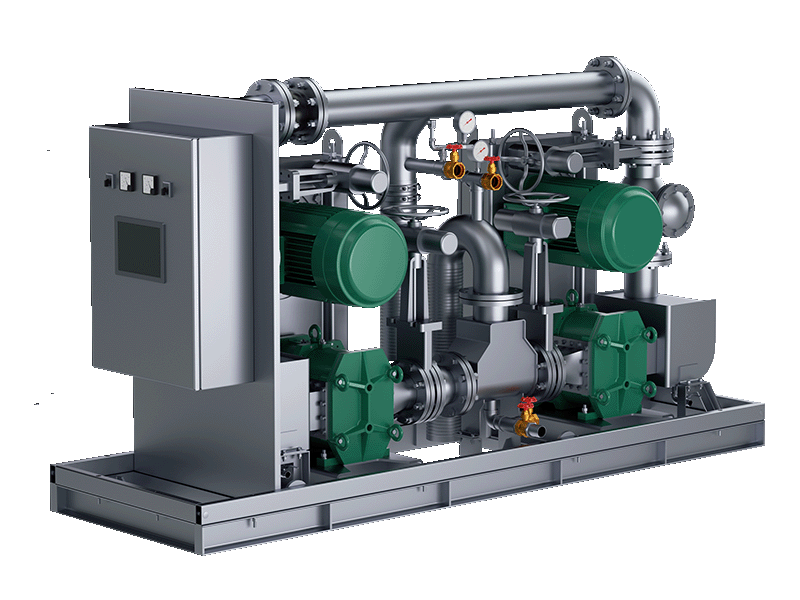

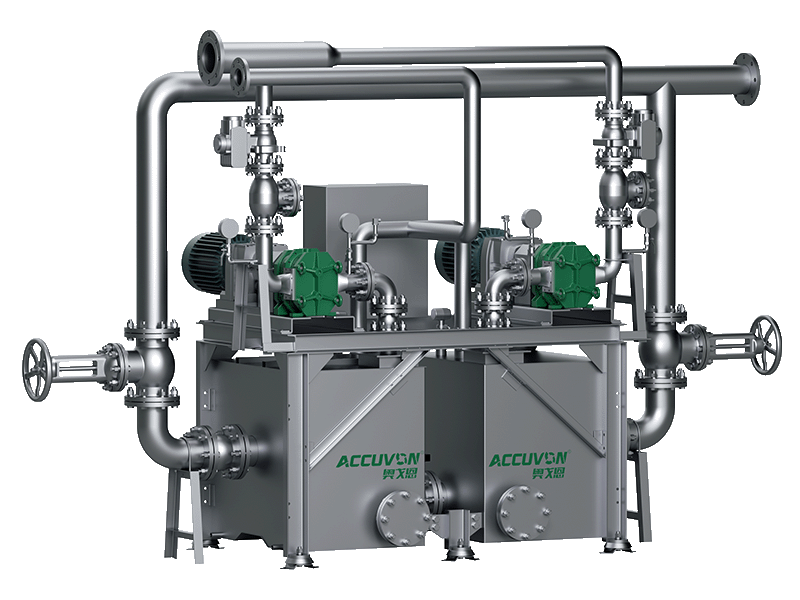

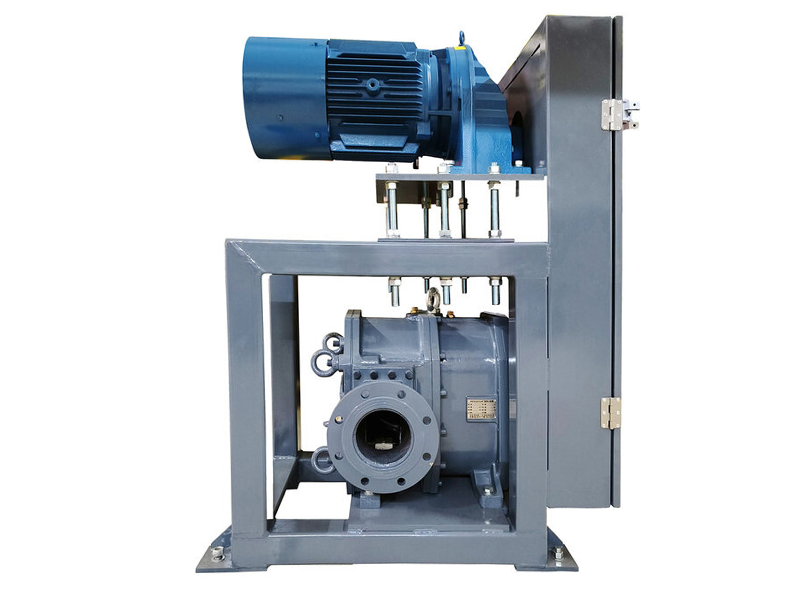

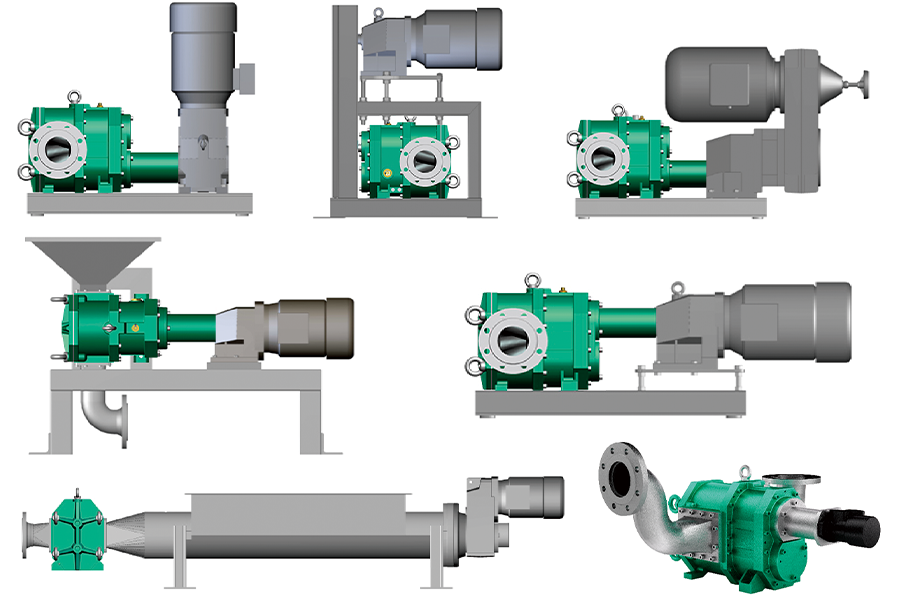

Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)are specifically designed to handle the unique characteristics of food waste slurries, which may include solid particles, semi-solid materials and liquids. It typically has a sturdy construction with corrosion- and wear-resistant materials, as well as components designed to prevent solid blockage and damage.

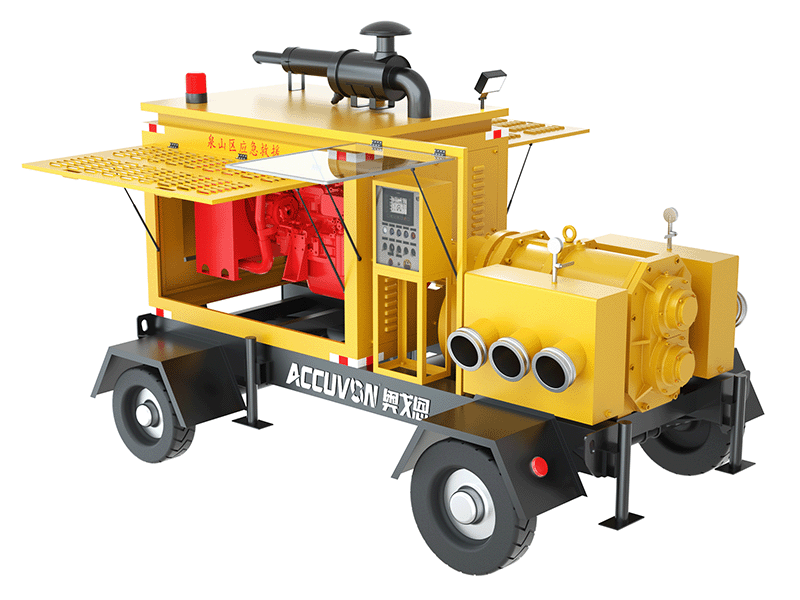

Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)are essential for effective waste management, diverting food waste to treatment or disposal facilities. They play a vital role in reducing environmental impact by promoting the correct handling and processing of organic waste.

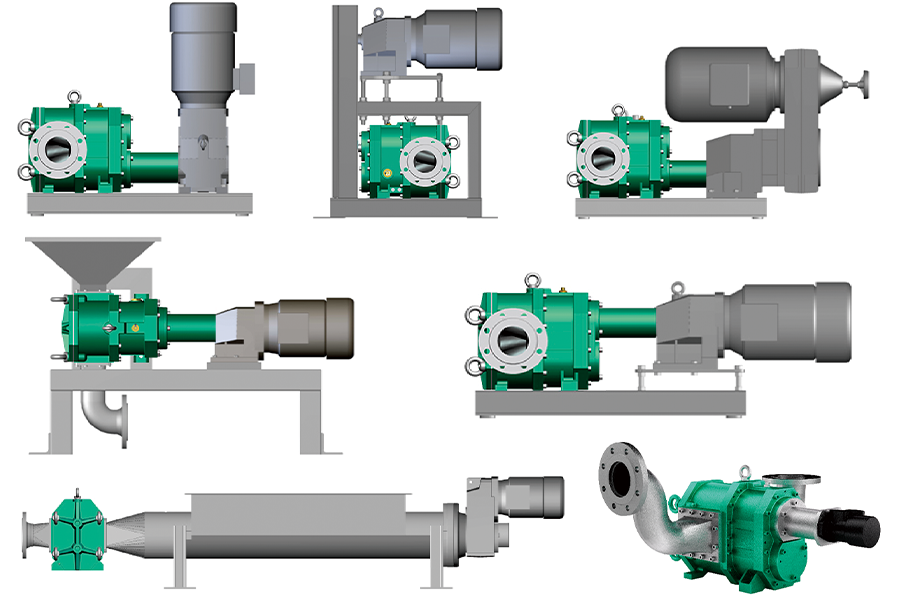

Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)are specialized equipment used to effectively handle and manage food waste. These pumps are designed to transport all forms of food waste including solid, semi-solid and liquid. They play a vital role in the waste management process, especially in industries such as food processing, hospitality and municipal waste disposal. Here are some key aspects of Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s):

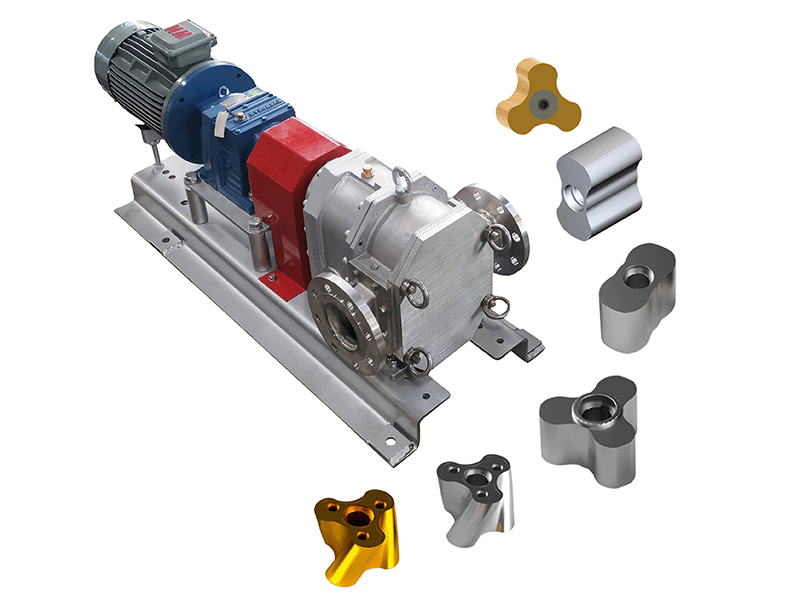

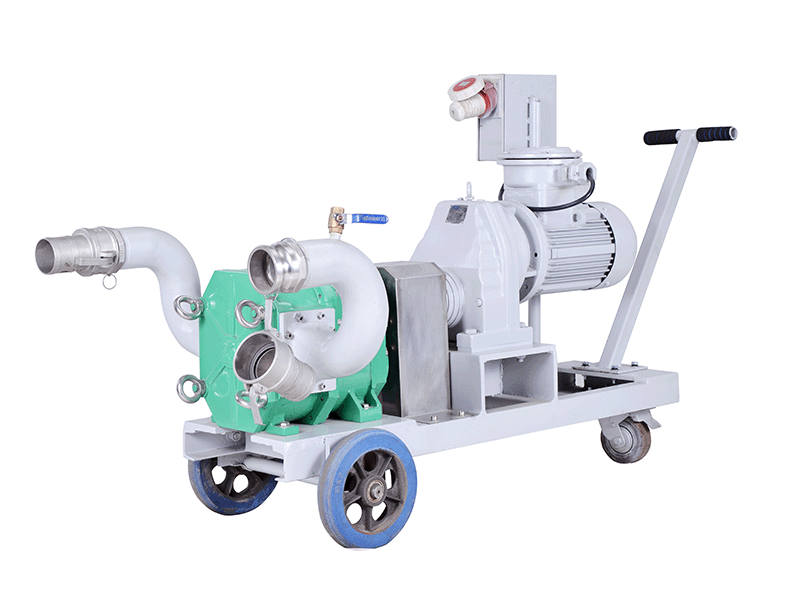

- 1. Versatility: Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)are versatile and can handle a variety of food waste, including organic solids, slurries, greases, oils, and liquids. These pumps can be used for various forms of food waste, including solid, semi-solid and liquid waste, and are therefore suitable for different types of waste disposal facilities and sites.

- 2. Corrosion resistance: Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)are usually made of corrosion-resistant materials to cope with corrosive substances that may be present in the garbage, such as acids or alkalis in food.

- 3. Wear resistance: Since food waste may contain solid particles or abrasive materials, these pumps are usually designed with high wear resistance to ensure long-term stable operation.

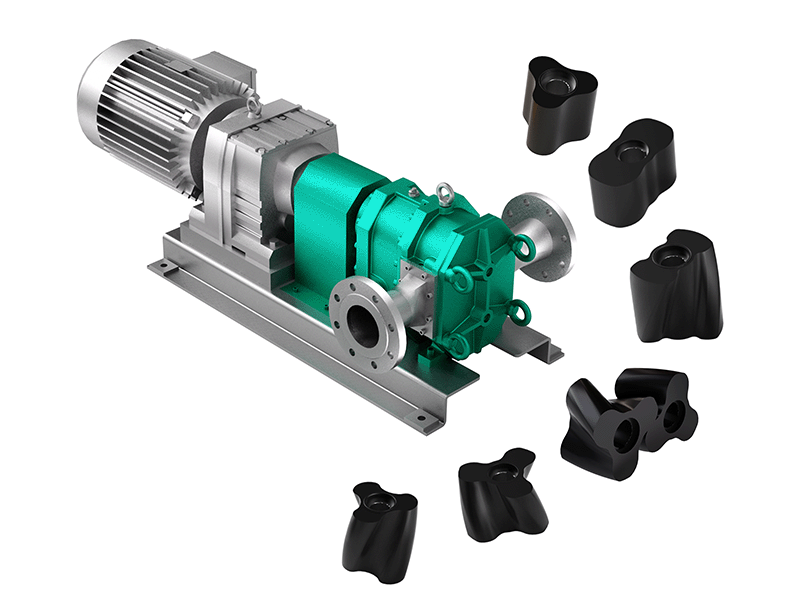

- 4. Anti-clogging design: In order to prevent solid particles from clogging the internal components of the pump, Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)usually have special designs, such as large-diameter feed inlets, professional filtration systems or special-shaped wear-resistant rotor(lobe), and special Design features such as sealing to prevent clogging and maintain efficient operation, even when handling challenging waste materials.

- 5. Applications: Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)have a variety of applications, including transferring food waste from collection points to treatment or disposal facilities, macerating or grinding solid waste to facilitate processing, and pumping food waste slurries for further processing or treatment.

- 6. Efficiency and Sustainability: Using Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)in the waste management process helps improve efficiency by reducing manual handling and simplifying waste transportation. Proper management of food waste can also contribute to sustainability by minimizing environmental pollution and promoting energy and resource recovery through methods such as anaerobic digestion or composting.

Generally speaking, Food waste slurry pump(Food waste slurry pump(Food Waste Pumps)s)play an important role in the catering and food processing industries, helping to realize the automation and efficiency of waste disposal, helping to reduce environmental pollution and promote the effective use of resources.

Food waste slurry pump(Food Waste Pumps)have many advantages in the field of waste disposal, mainly reflected in the following aspects:

- 1. Efficient processing: The Food waste slurry pump(Food Waste Pumps)continuously and evenly transports food waste to the destination through the rotation of the cam, and has high transport capacity and efficiency. They can handle large amounts of garbage and can adjust the conveying speed and flow rate as needed, improving the efficiency of garbage treatment.

- 2. Reduce pollution: By transferring and processing food waste in a timely manner, the odor, decay and the growth of infectious bacteria produced during the storage of the waste can be reduced, thereby reducing pollution to the surrounding environment and air quality.

- 3. Save space: compact design, small footprint, suitable for various site conditions. Compared with traditional waste conveying methods, the cam pump can effectively use space, saving the space required for storing and processing food waste.

- 4. Resource recovery: Part of the food waste can be converted into organic fertilizer or bioenergy through the treatment process. Effective treatment using a Food waste slurry pump(Food Waste Pumps)can help realize the recycling of resources and promote sustainable development.

- 5. Anti-clogging design: Food waste slurry pump(Food Waste Pumps)usually have a specially designed spiral structure, which can effectively prevent clogging of solid particles and ensure smooth transportation of garbage. This helps reduce downtime and maintenance costs.

- 6. Reliable and stable: Food waste slurry pump(Food Waste Pumps)are usually made of wear-resistant and corrosion-resistant materials, with long service life and stable performance. They can operate stably in harsh working environments and require less maintenance and upkeep.

- 7. Environmental protection: Using Food waste slurry pump(Food Waste Pumps)for transportation can reduce energy consumption and carbon emissions in the waste treatment process. In addition, some food waste can be converted into organic fertilizer or bioenergy through appropriate treatment methods, promoting resource recycling and environmental protection.

To sum up, the kitchen waste pump has many advantages in garbage disposal and environmental protection. It can effectively solve the problems in the kitchen waste disposal process and promote the sustainable development of the waste disposal industry.

The application scope of Food waste slurry pump(Food Waste Pumps)covers multiple fields and scenarios, mainly including the following aspects:

- 1. Catering industry: In the catering industry, a large amount of food waste is generated in kitchens and restaurants. Food waste slurry pump(Food Waste Pumps)can be used to transport food waste slurry from the kitchen to post-processing equipment such as garbage disposals, sewage treatment facilities or composting plants for further processing or recycling.

- 2. Food processing plants: Food processing plants often generate large amounts of food waste and by-products. Food waste slurry pump(Food Waste Pumps)can be used to transport these waste and by-products to treatment facilities such as bioenergy power plants, fermenters or anaerobic digesters for energy recovery or the production of organic fertilizers.

- 3. Hotels and guesthouses: In hotels and guesthouses, a large amount of food waste is generated every day. Food waste slurry pump(Food Waste Pumps)can be used to collect and transport this waste from various departments or rooms to a central processing site for unified treatment and management.

- 4. Food waste treatment plants: Food waste treatment plants are facilities specifically designed to process food waste. These manufacturers usually use Food waste slurry pump(Food Waste Pumps)to transport large amounts of food waste slurry from different sources to the treatment facilities for processing. Classification, decomposition, fermentation or other processing.

- 5. Municipal Waste Treatment Center: The Municipal Waste Treatment Center is responsible for processing all types of waste within the city, including food waste. Slurry pumps can be used to transport food waste collected in cities to central processing facilities for unified treatment and disposal.

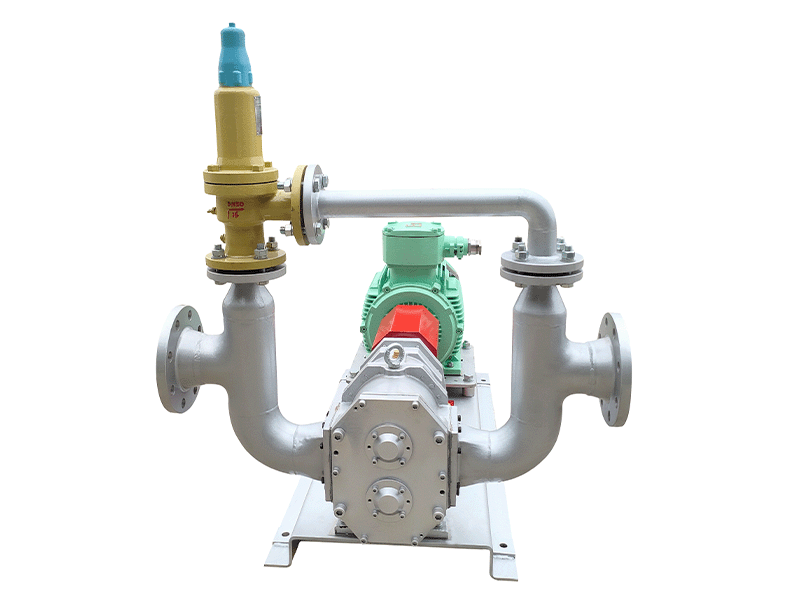

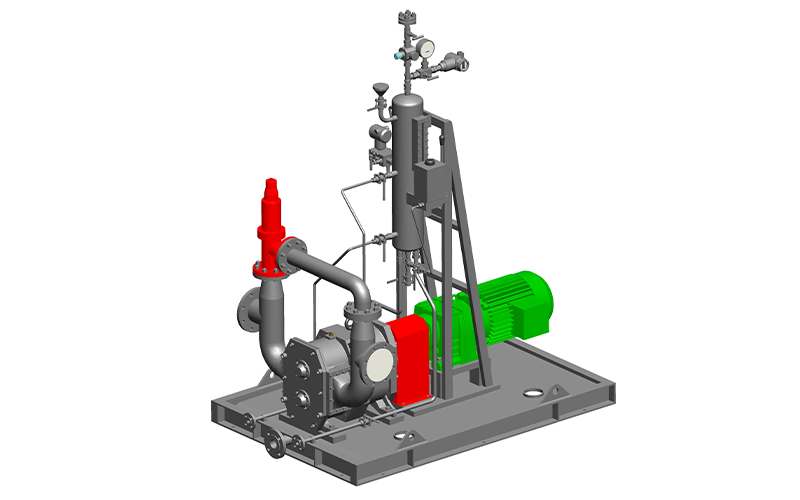

In the above different application scenarios, Food waste slurry pump(Food Waste Pumps)are usually used in the following process links when processing food waste:

- 1. Collection and transportation: Food waste slurry pump(Food Waste Pumps)are used to transport food waste collected from catering industries, food processing plants, hotels and other places to treatment facilities. This waste is usually in liquid or semi-solid form and needs to be transported by slurry pumps.

- 2. Pretreatment: During the food waste treatment process, the waste may need to be pretreated, such as removing large solids, separating grease, etc. Food waste slurry pump(Food Waste Pumps)can be used to transport waste to pre-treatment equipment such as filters, sedimentation tanks or separators.

- 3. Mixing and stirring: Some food waste treatment processes require mixing and stirring of waste from different sources or types to promote biodegradation or other treatment processes. Food waste slurry pump(Food Waste Pumps)can be used to transport different waste slurries to mixing tanks or mixing tanks for mixing reactions.

- 4. Biochemical treatment: Biochemical treatment is one of the common methods for treating food waste, including anaerobic digestion, aerobic fermentation and other processes. Food waste slurry pump(Food Waste Pumps)can be used to transport waste slurry to biochemical reactors to provide the raw materials and energy required for the reaction.

- 5. Solid-liquid separation: During the food waste treatment process, the solid-liquid separation of the garbage slurry may be required for further processing or disposal. Food waste slurry pump(Food Waste Pumps)can be used to transport the processed waste slurry to equipment such as centrifuges, filter presses or filter presses for solid-liquid separation.

- 6. Transport to disposal or recycling facilities: After treatment is completed, the Food waste slurry pump(Food Waste Pumps)can be used to transport the processed waste slurry to a disposal facility, such as a landfill or incineration plant, for final disposal; or to a recycling facility, Such as composting sites or bioenergy power plants for resource recycling.

To sum up, Food waste slurry pump(Food Waste Pumps)are widely used in many fields and scenarios such as catering industry, food processing plants, hotels, food waste treatment plants and urban waste treatment centers.