Technical Data |

|

|

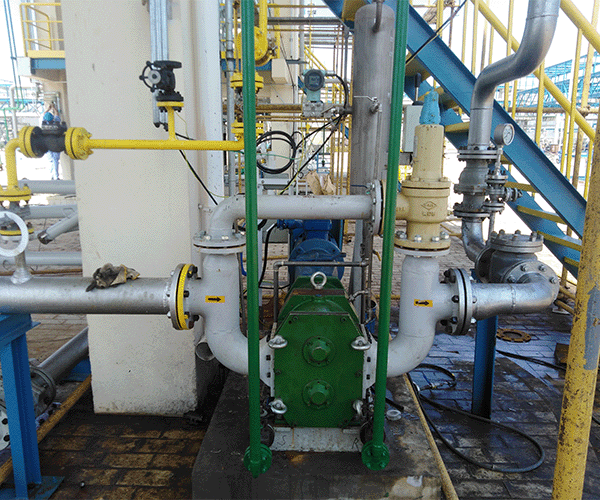

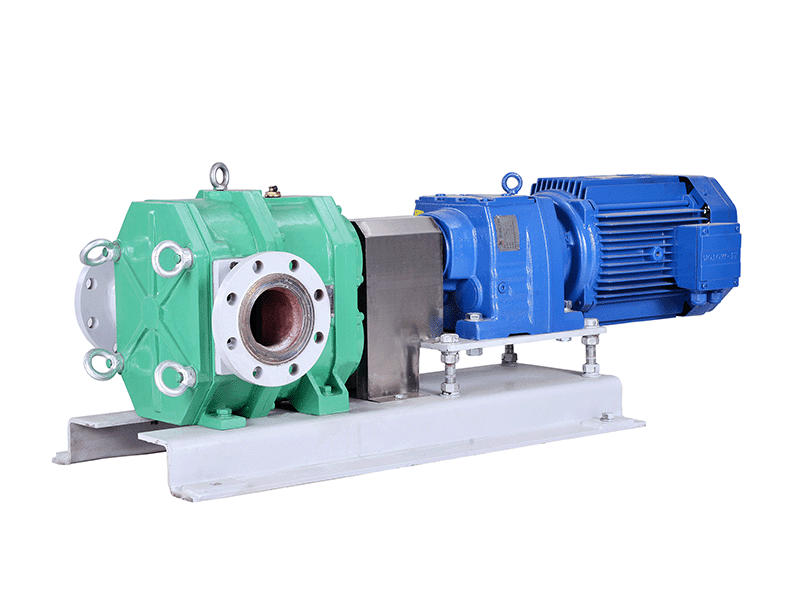

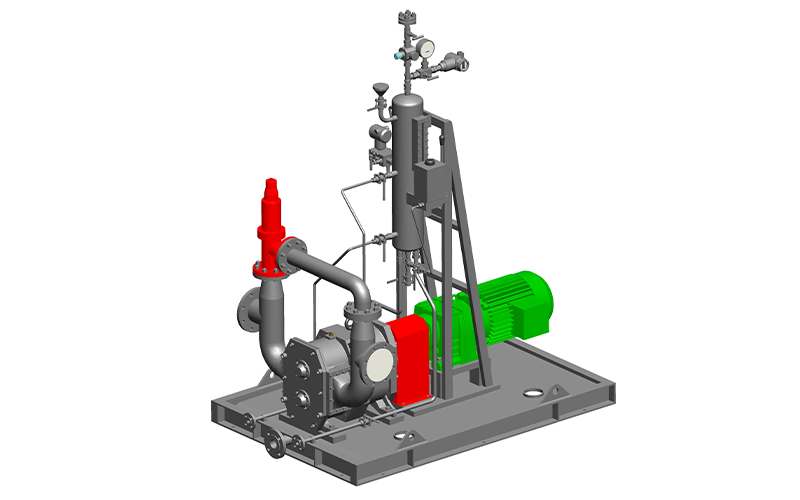

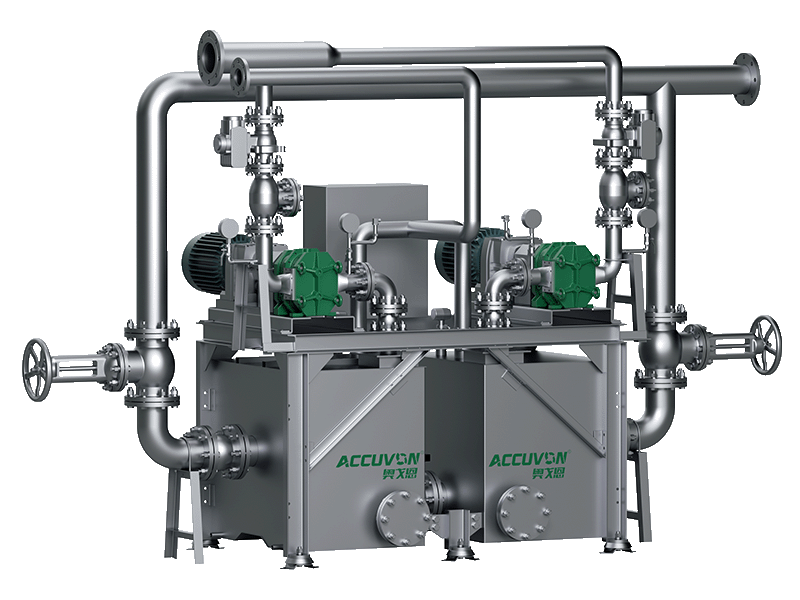

Water pump |

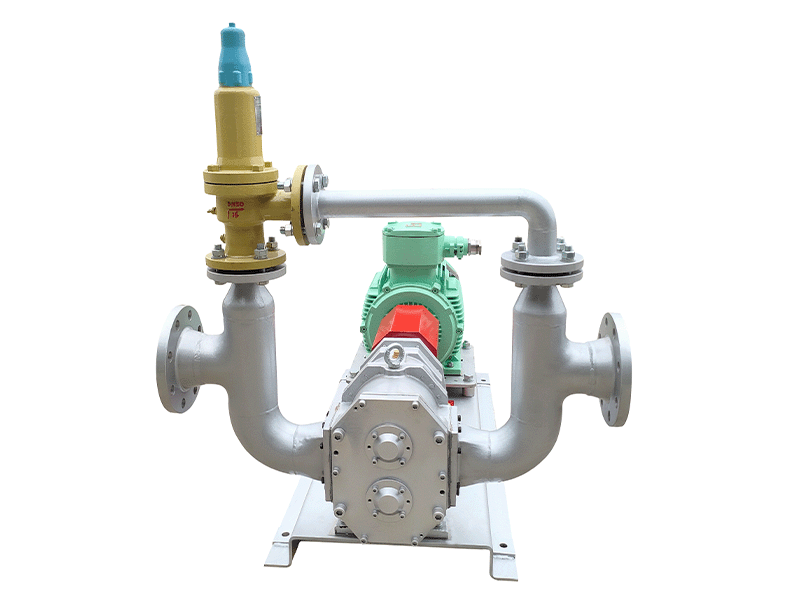

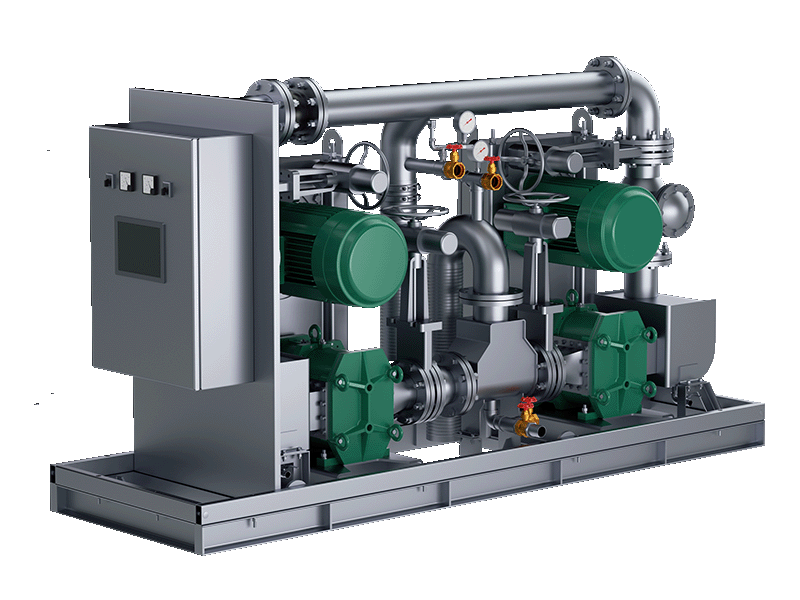

Oil pump |

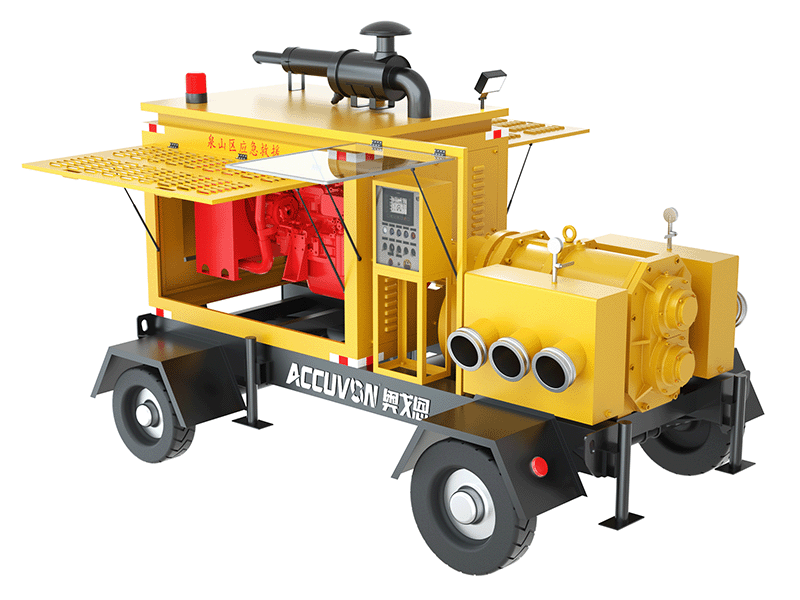

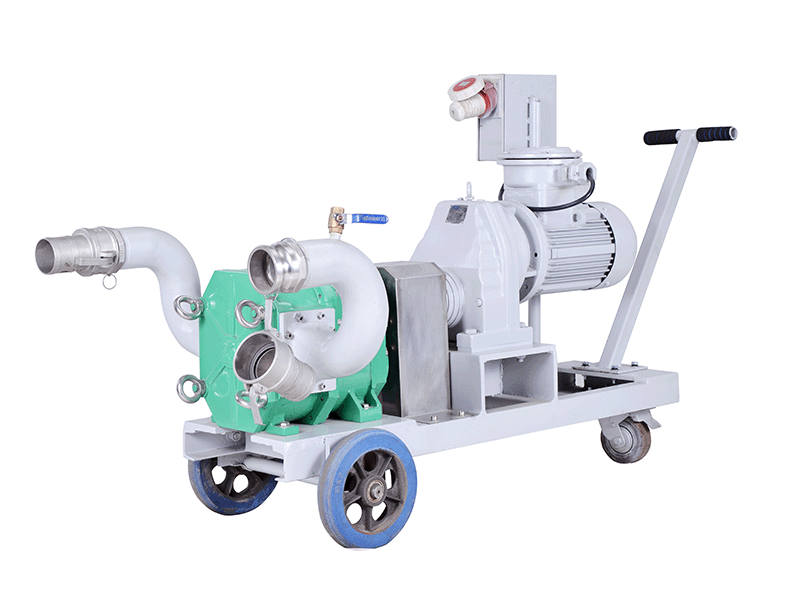

Mobile pump |

|

Type: |

AP140 |

AP120 |

AP120 |

|

Capacity: |

60-80 m3/h |

40~50m3/h |

50m3/h |

|

Pressure: |

2bar |

4bar |

4bar |

|

Power: |

11kw |

11kw |

11kw |

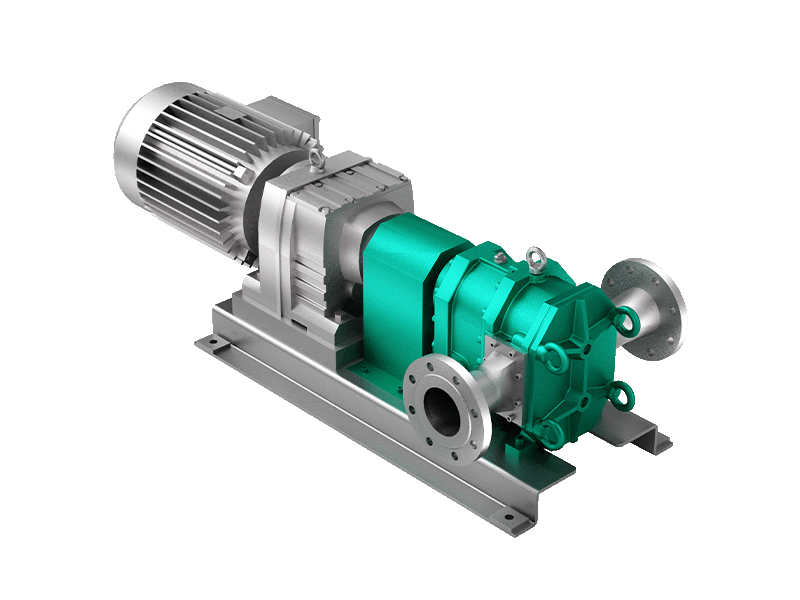

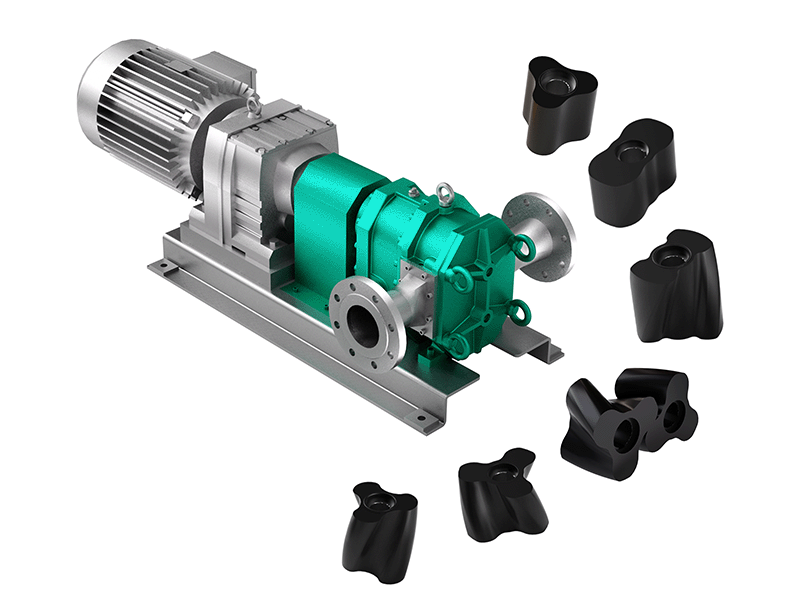

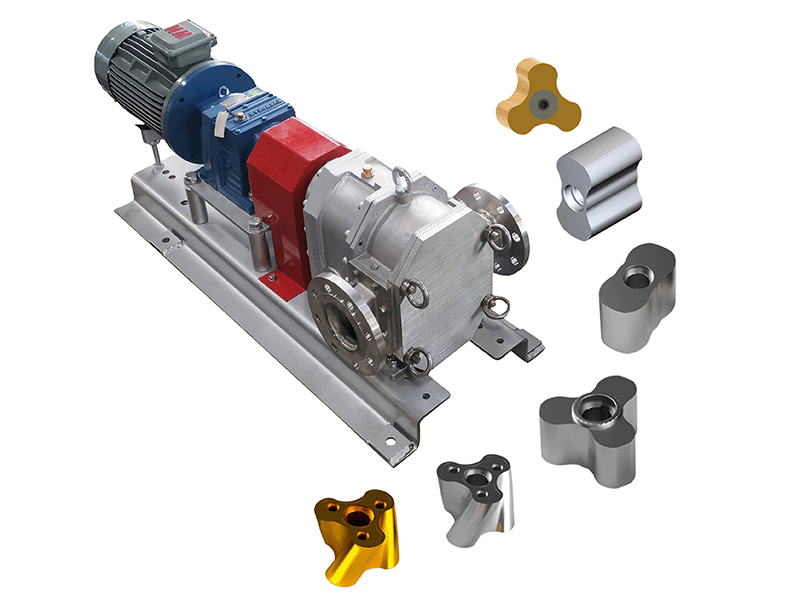

Advantages |

- Maintenance-friendly in the outstanding MIP design

- Pulsation-free operation by use of screw rotor geometry

- Speed-proportional flow with easy reaction to changes in viscosity and pressure

- Commonalty of all installed pumps with identical components

- Self-priming, insensitive to solids and high temperatures

- Alternatively available as per ATEX, for use in Zone 1 or Zone 2 The external feed pump can also be used for other duties, e.g. water flooding

- No emulsification of the oil-water-mixtures due to low shear effect and low speeds

- Small foot print required.

- The fix installed pumps need only app. 900x1100x500 mm

- Alternatively available with hydraulic motors