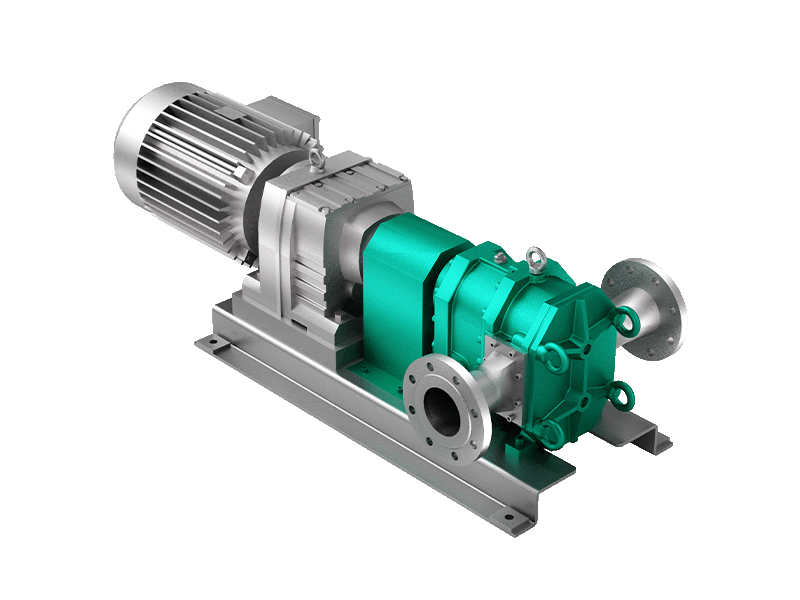

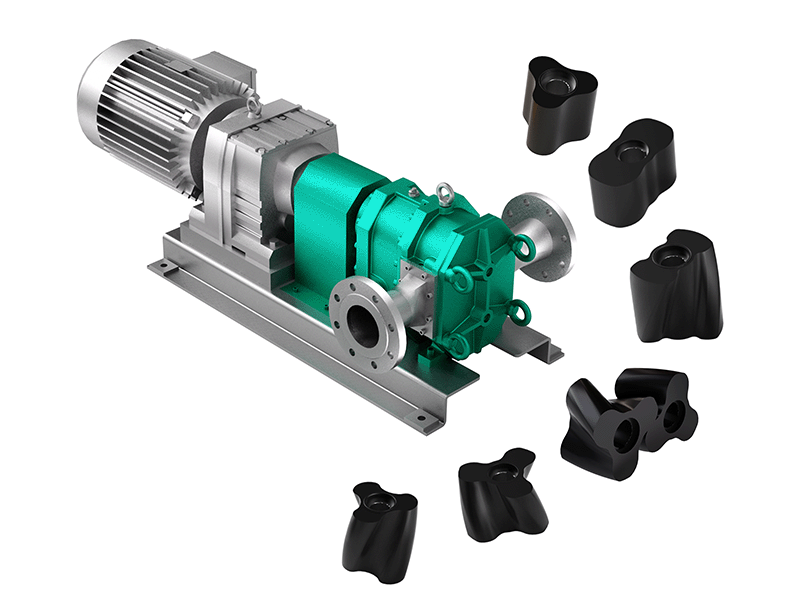

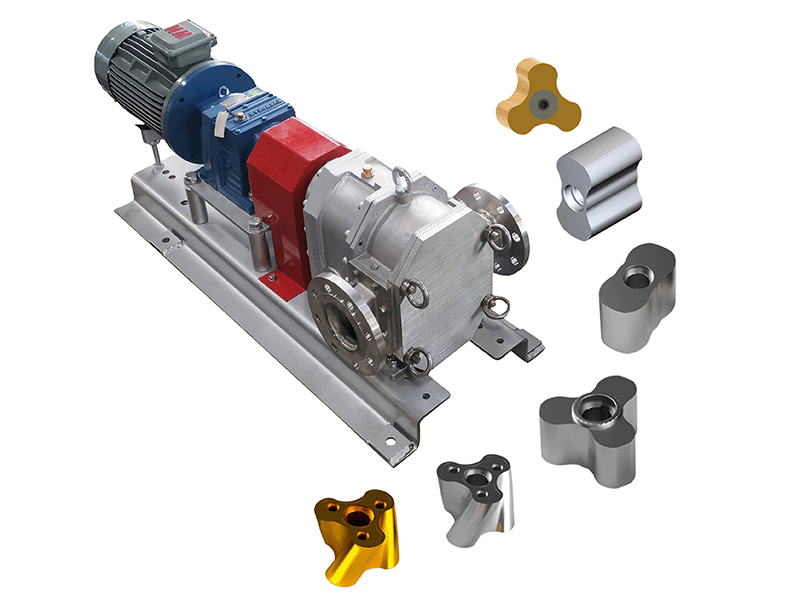

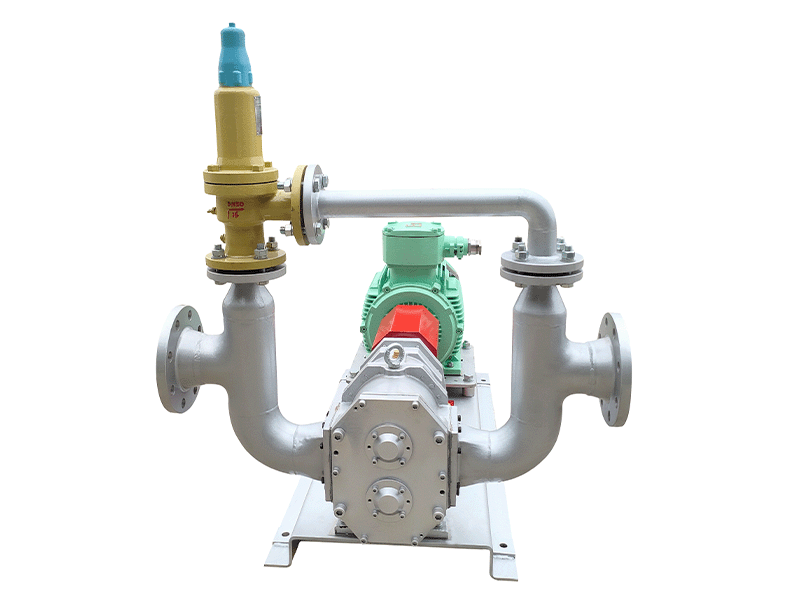

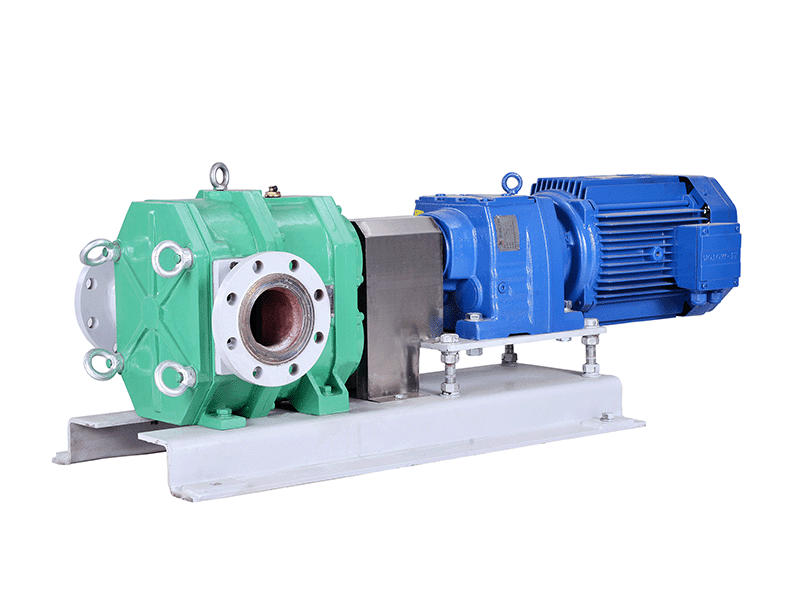

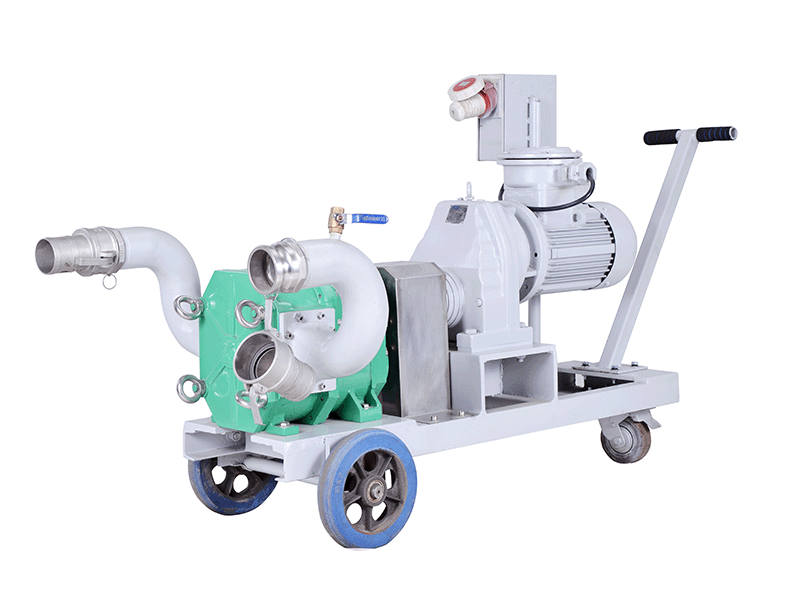

ACUUVON rotary lobe pump is a positive displacement pump, in line with the American Petroleum Industry Association API676 standards, with a low speed (350RPM), suction ability (maximum vacuum of -0.085MPa), high efficiency (70-85%), conveying exasperating liquid mixing, without air resistance, non blocking, characterized by strong low impurity. There are many applications in the field of oil extraction, storage, transportation and refining of crude oil.

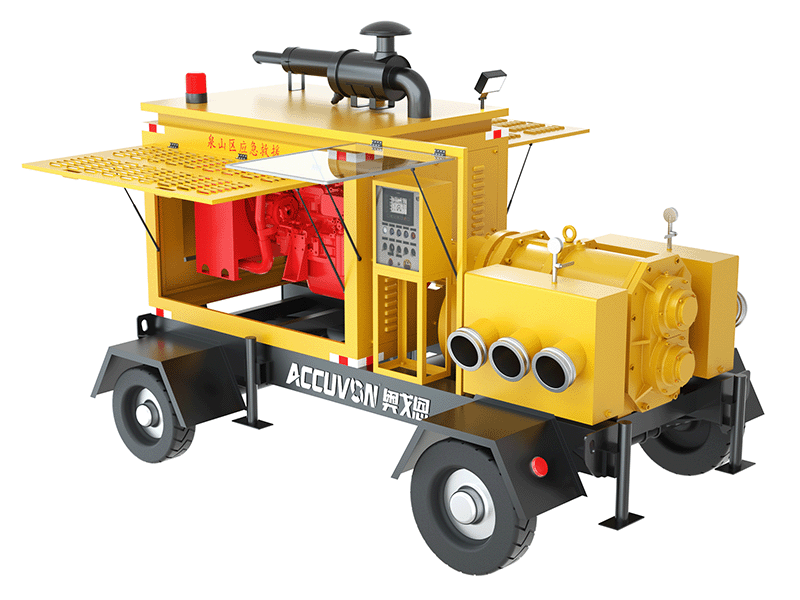

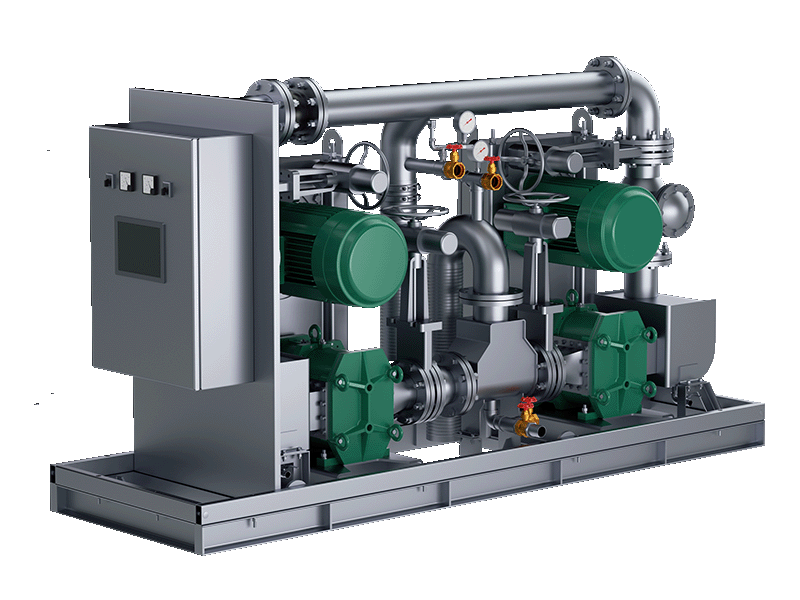

Exploring innovation and leading the future, ACCUVON lobe pumps shined at the Xinjiang International Petroleum and Chemical Technology Equipment and Explosion-proof Electrical Exhibition in 2019. As an industry leader, we demonstrate our latest lobe pump solutions to exhibition visitors with our excellent technology and reliable quality.

At the exhibition, the ACCUVON lobe pump attracted the attention of many professional visitors with its high efficiency, energy saving, stability and reliability. Our products demonstrate a variety of applications in the petroleum and chemical industries, demonstrating our leading position in the industry and our ability to continuously innovate.

ACCUVON lobe pumps are not only representatives of technology, but also a commitment to environmental protection and safe production. We will continue to be committed to providing customers with excellent products and services, and working with industry partners to create a better future.

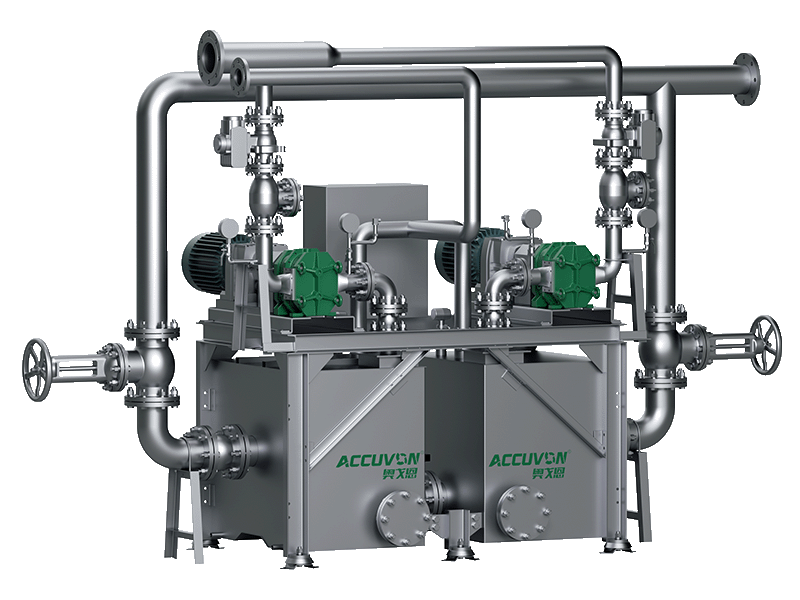

Lobe pumps play an important role in the oil field industry and are mainly used in the following aspects:

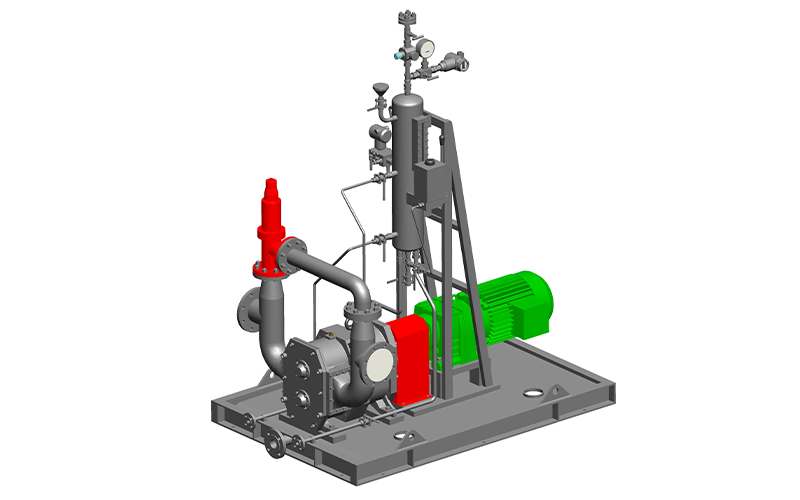

Oil Well Production: Lobe pumps are used to extract crude oil from oil wells. They are capable of operating under extreme conditions, including high pressure, high temperature and high viscosity reservoirs.

Injecting liquids: During oil field production, water or other liquids need to be injected to maintain reservoir pressure or promote recovery. Lobe pumps can be used to move injection fluids from storage facilities to the wellhead.

Chemical Injection: In oil field development, chemicals are sometimes injected to treat bottomhole sediments, improve reservoir productivity, or reduce problems during production. Lobe pumps can be used to deliver these chemicals.

Advantages of lobe pumps in the oil field industry include:

High efficiency: The lobe pump has a simple design and high efficiency, which can transport liquid from one place to another quickly and reliably.

Strong adaptability: Lobe pumps are suitable for various oil field environments, including extreme conditions such as high pressure, high temperature and corrosive media.

Reliability: The lobe pump has a simple structure, stable operation, low failure rate, and can operate continuously for a long time.

Easy to maintain: The parts of the lobe pump are relatively simple and easy to maintain and replace, reducing downtime and maintenance costs.

Energy saving and environmental protection: Lobe pumps usually provide high-efficiency delivery, reduce energy consumption, and also help reduce carbon emissions.

In general, the lobe pump plays a key role in the oil field industry. Its high efficiency, reliability and adaptability make it one of the indispensable equipment in the oil field production process.