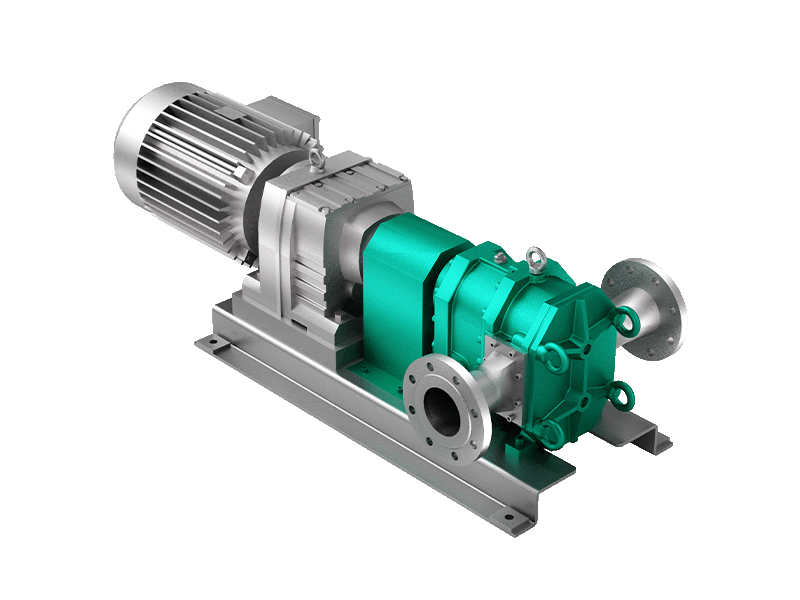

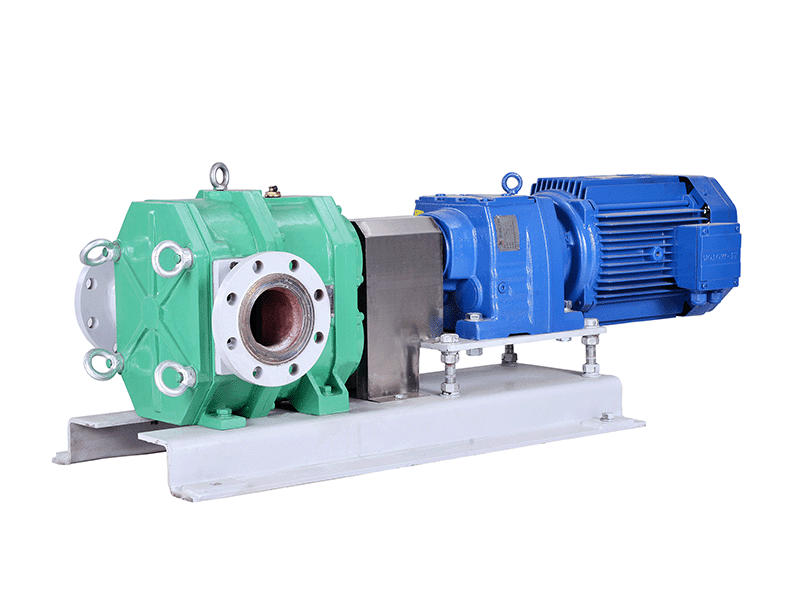

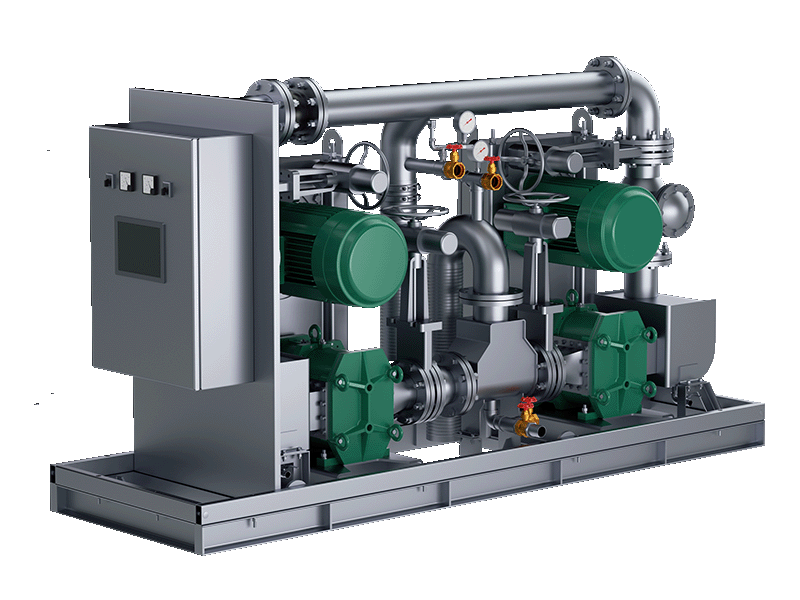

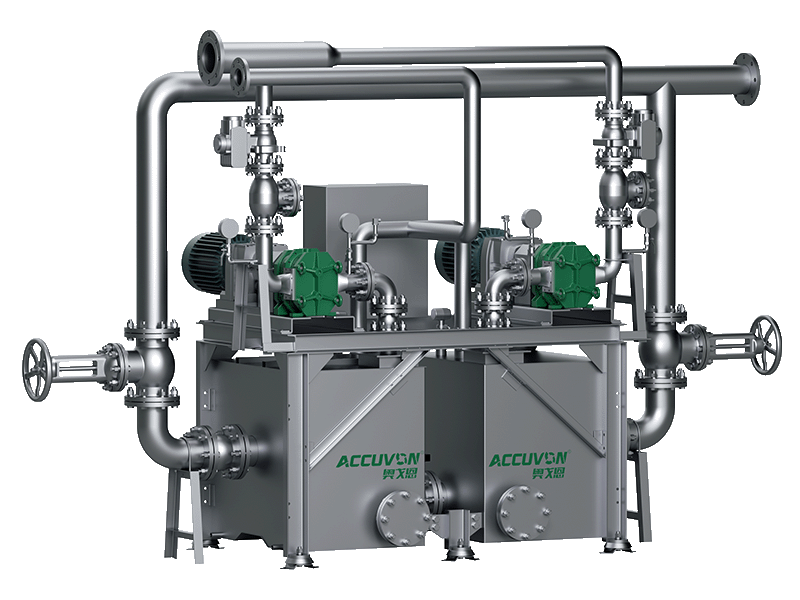

ACCUVON lobe pumps play a very important role in petrochemical applications, and their product technology has obvious advantages. Lobe pumps manufactured using API676 standards have the following characteristics:

1. The shaft is made of American standard 4140 high-quality alloy steel

2. AGMA level 9 precision high standard synchronization gear

3. Oil temperature drops or overheats, shutdown protection

4. Radial wear-resistant lining plate prevents the pump casing from being worn

5. Quickly open the pump cover to ensure online maintenance

6. The high-pressure pump can be equipped with a double-support pump cover design.

7. Axial wear-resistant lining plate is replaceable and reduces operating costs.

8. Spiral multi-blade rotor, low pulsation, small vibration, efficient operation

9. Use balanced mechanical seal, high pressure resistance, long life and simple maintenance

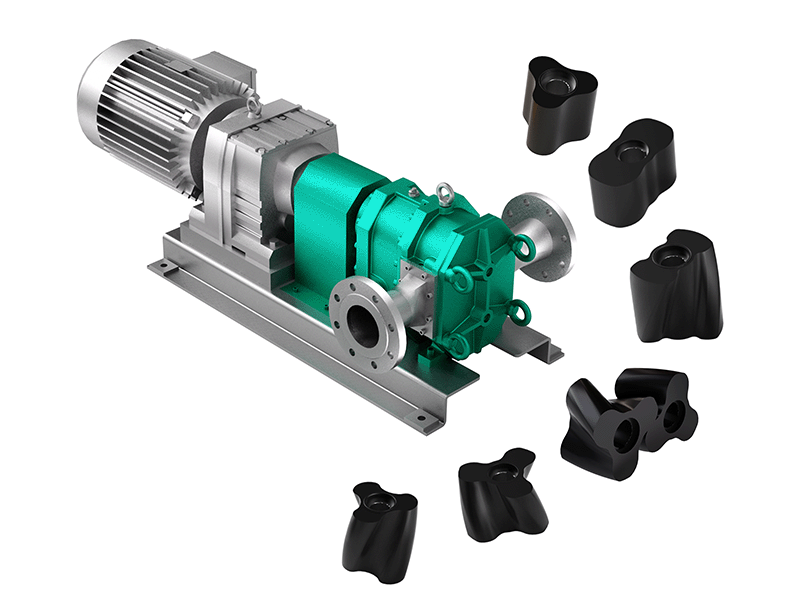

All-round wear-resistant design

Wear-resistant rubber low-pulsation rotor

Particularly suitable for abrasive media. Simple design style. Quick-open pump cover, online maintenance, economical life cycle running costs, and comprehensive wear-resistant lining protection to ensure that the pump shell will not be worn for life.

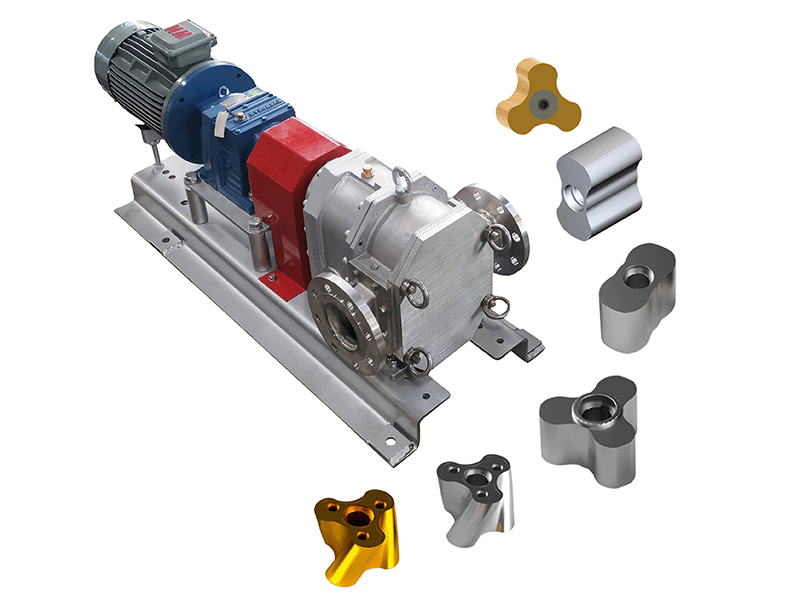

High precision and high efficiency rotor design

ACCUVON rotors are available in a variety of styles and materials:

NBR nitrile rubber

EPDM ethylene propylene diene rubber

FPM fluororubber

FFKM perfluoroelastomer

Pu polyurethane

Pure copper rotor

PTFEPolytetrafluoroethylene

304 stainless steel, 316 stainless steel, 316L stainless steel, two-way stainless steel, etc.

Based on the above important characteristics, ACCUVON lobe rotor pumps are also widely used. The following is an introduction to the more important typical applications in the petroleum and chemical industries:

Application occasions

1. Tank bottom oil pump, tank bottom clearance pump

2. Heavy oil, fuel oil, refined oil, chemical product unloading pump 3. Sludge, oily sludge pump, sewage oil pump, residual oil pump

4. Crude oil. Heavy oil and light oil loading and shipping pumps

5. Sweeping pump, sweeping line pump

6. Oily sewage lift pump, sewage oil lift pump, accident water lift pump (self-priming pump)

7. Scum, suspension and foam suction pump

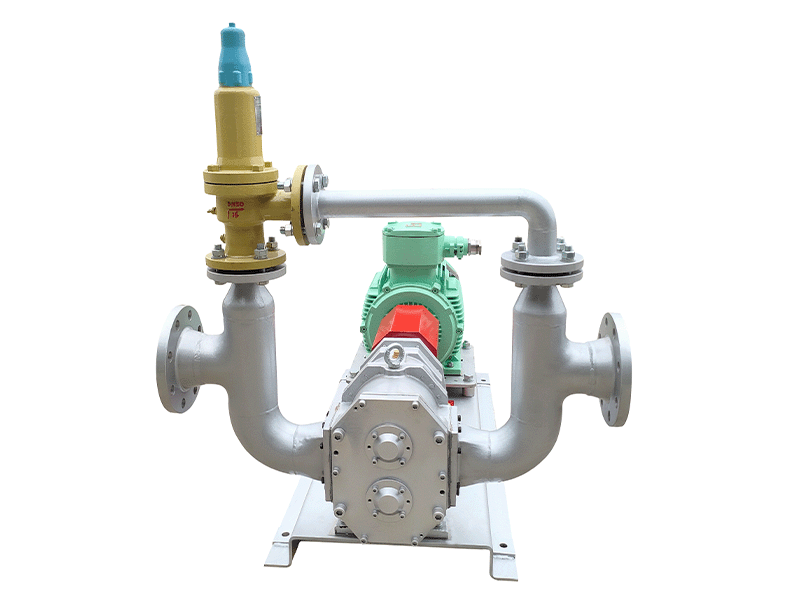

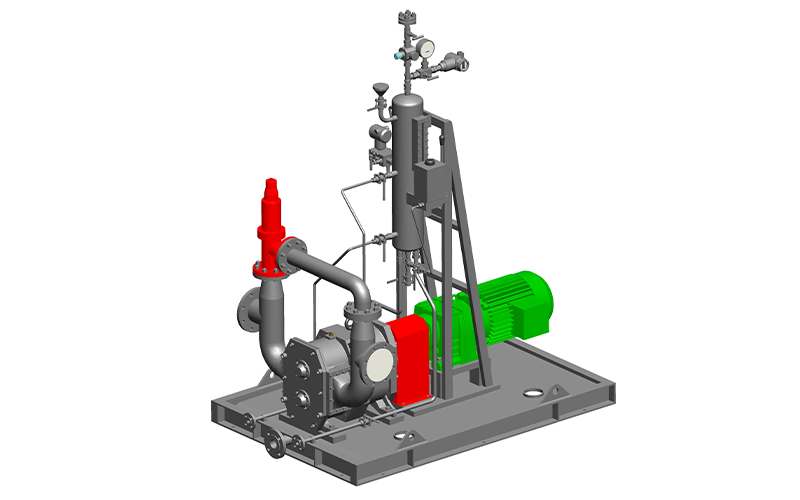

Oil and chemical product unloading pump

Unloading pumps (trains, cars) are often used in

1. Heavy oil unloading pump:

Heavy oil, fuel oil, crude oil, residual oil, etc. unloading trucks

2. Light oil unloading pump:

Unloading trucks of gasoline, diesel, jet fuel, naphtha, etc.

3. Chemical unloading pump:

Methanol, ethanol, concentrated sulfuric acid, 50% liquid alkali, 85% phosphoric acid, etc. Unloading truck

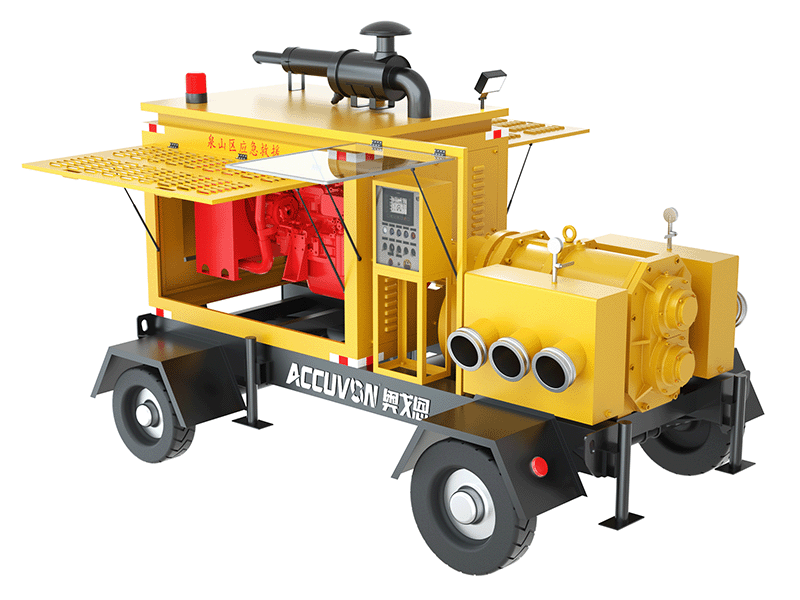

Dirty oil and sewage lifting pump (self-priming pump)

Applications of self-priming lift pumps

1. Oily sewage lifting pump

2. Dirty oil lifting pump

3. Accident water lifting pump

4. Initial rainwater lift pump

5. Sewage collection tank (buried tank) sewage oil and sewage lifting pump

6. Oilfield waste oil and sewage self-priming lifting pump

Tank bottom oil pump, backfill pump

Application advantages:

1. Strong suction ability, capable of mixed transportation of gas, liquid and solid. 2. Wear-resistant, no clogging, strong ability to pass solids

3. Can be evacuated and run dry

4. High efficiency

5. Adapt to media with low viscosity to high viscosity changes

6. Flexible operation, with mobile and fixed installation options available

Sludge pump, sewage oil pump

Application advantages:

1. Wear-resistant, often used in centrifuge sludge feeding, thickening tank sludge lifting and screw replacement

2. High viscosity resistance and high efficiency

3. Compact size, saving civil construction costs

4. Simple maintenance and low cost of accessories

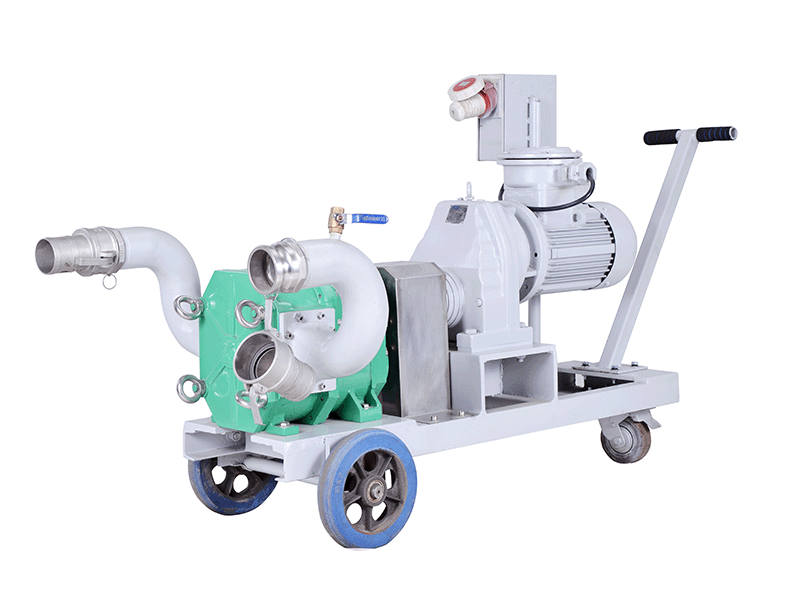

Mobile dirty oil and sewage suction pump

Application advantages:

1. Strong self-priming ability, mixed gas and liquid transportation, no need to prime the pump

2. Quick connection, mobile operation, can be matched with motor, diesel engine, gasoline engine, etc.

3. No clogging, can pass through fibers such as cloth strips

4. Applicable occasions: sewage pools, sewage oil pools, buried tanks or emergency applications