Rotary pumps play a crucial role in the environmental sector due to their efficiency, reliability, and versatility. These pumps, operating on the principle of rotating elements within a casing, offer distinct advantages that make them indispensable in various environmental engineering applications.

Basic Principles of Rotary Pumps

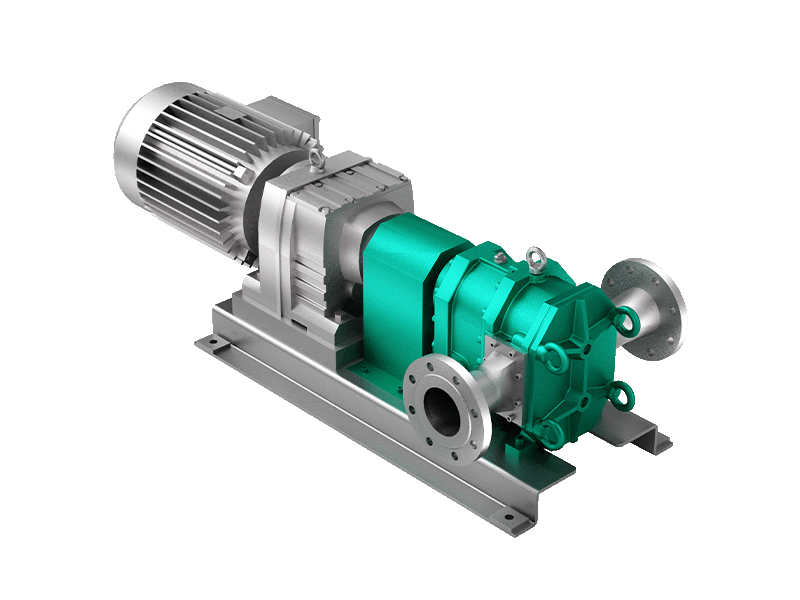

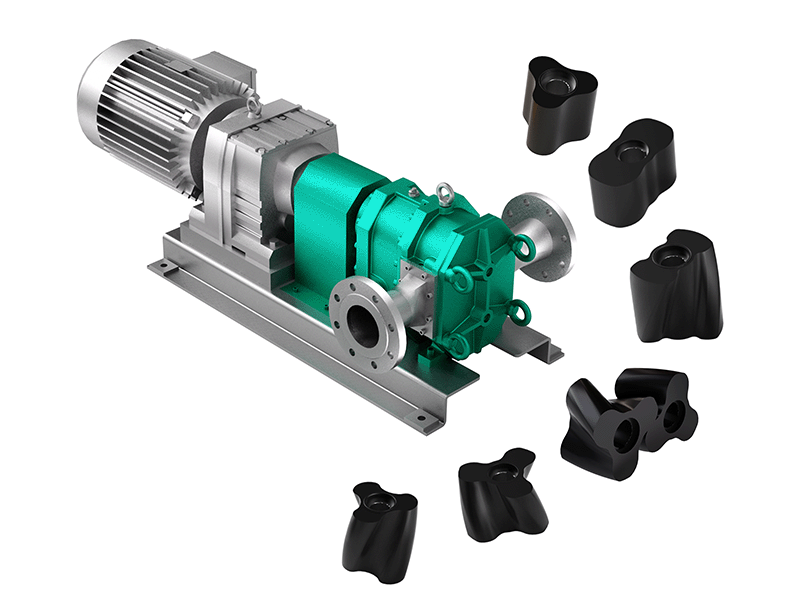

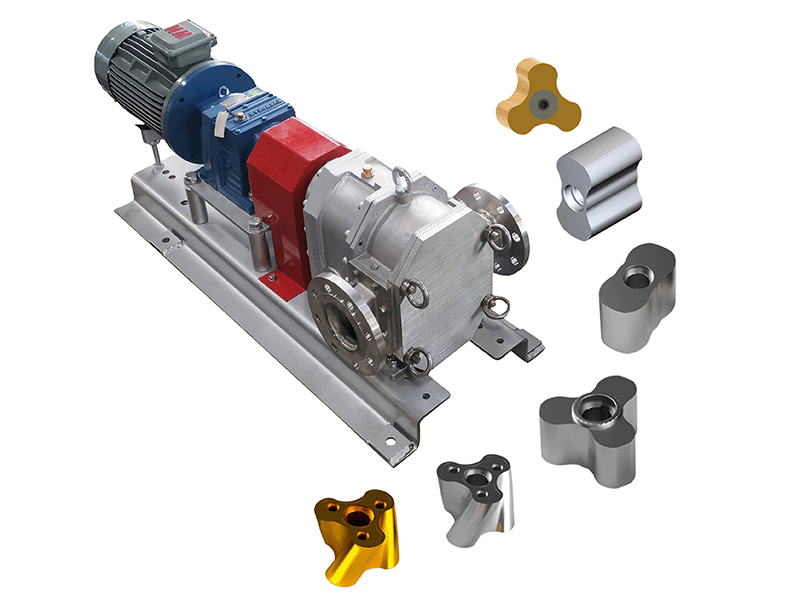

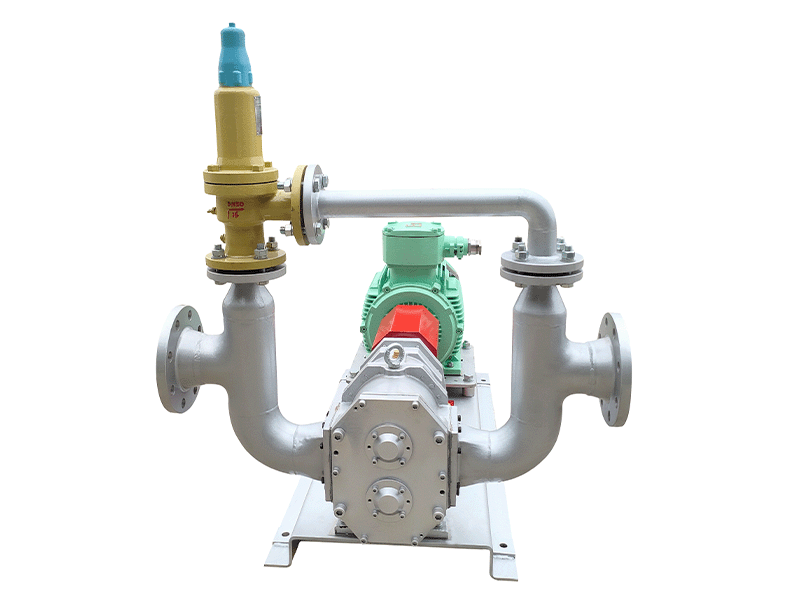

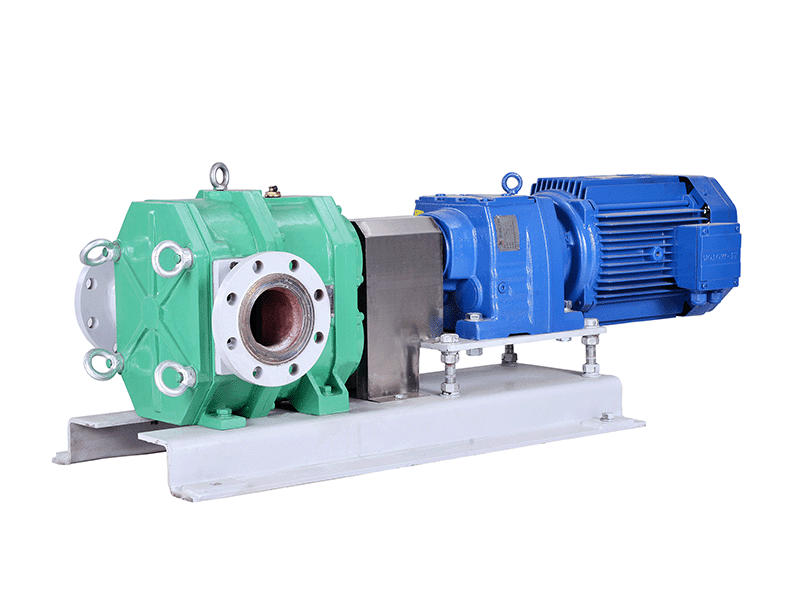

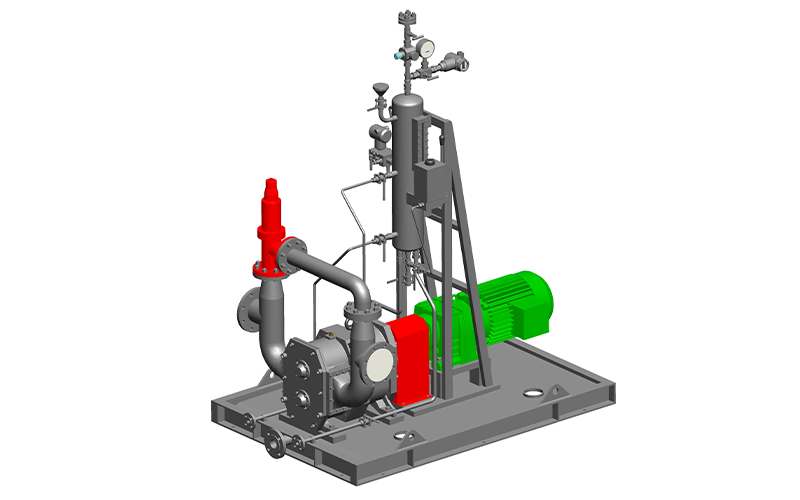

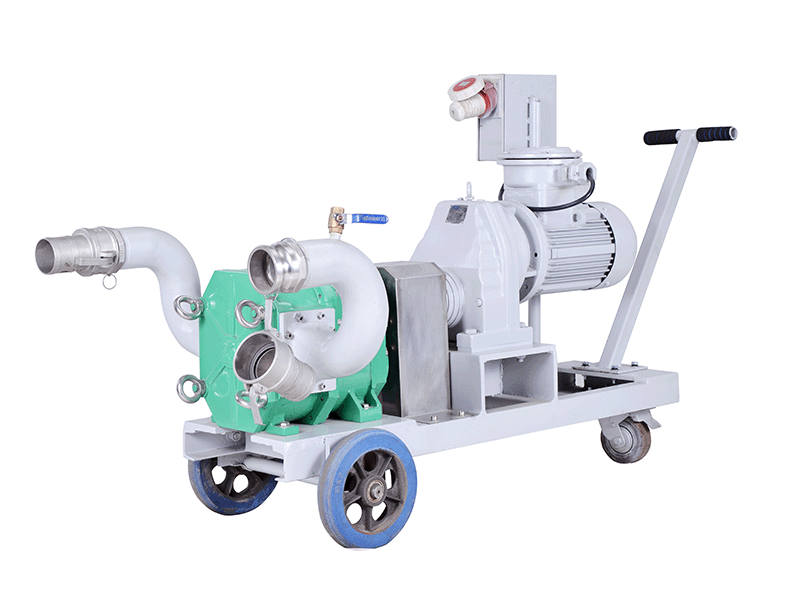

Rotary pumps, such as screw and gear pumps, operate by using rotating elements to create a suction that draws in fluids or gases. As the rotors or gears rotate, they trap and transfer the medium through the pump casing, facilitating efficient fluid handling. Their straightforward design and robust construction contribute to their high performance and durability.

Advantages of Rotary Pumps in the Environmental Industry

1. High Efficiency : Rotary pumps are known for their ability to handle high viscosity fluids and solids-laden liquids efficiently. This capability is crucial in processes involving wastewater treatment, sludge handling, and chemical processing where consistent and reliable pumping is essential.

2. Energy Efficiency : Compared to traditional centrifugal pumps, rotary pumps offer superior energy efficiency. They operate smoothly and require less energy to move fluids, contributing to lower operational costs and reduced environmental impact.

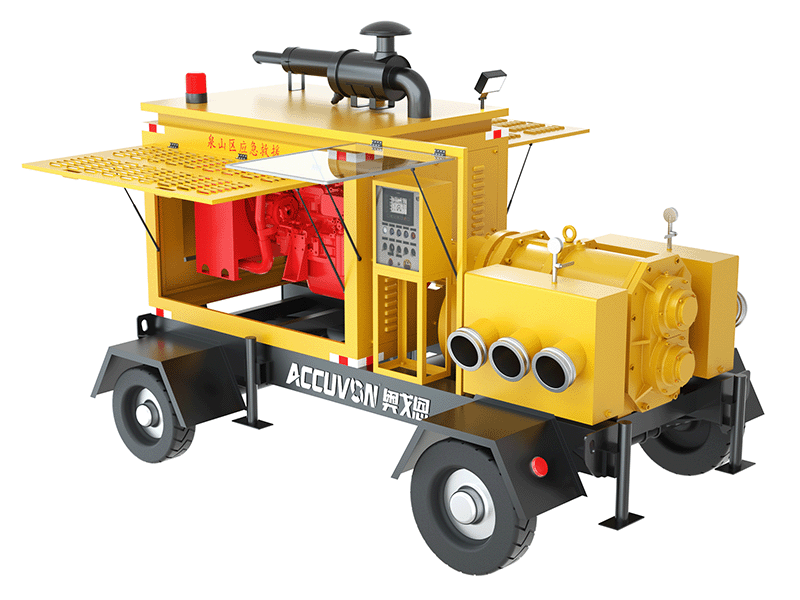

3. Versatility: Rotary pumps are versatile and can handle a wide range of fluids, including corrosive and abrasive substances. This makes them suitable for diverse applications in environmental engineering, such as chemical dosing, effluent transfer, and industrial wastewater management.

4. Reliability and Longevity : With fewer moving parts and robust construction materials, rotary pumps are designed for longevity and minimal maintenance. This reliability ensures continuous operation in demanding environmental conditions, minimizing downtime and enhancing operational efficiency.

Applications of Rotary Pumps in the Environmental Sector

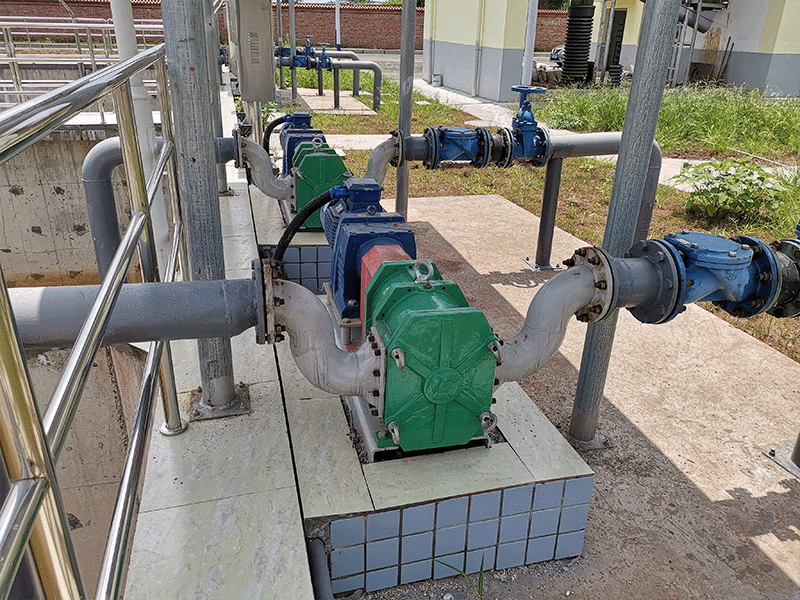

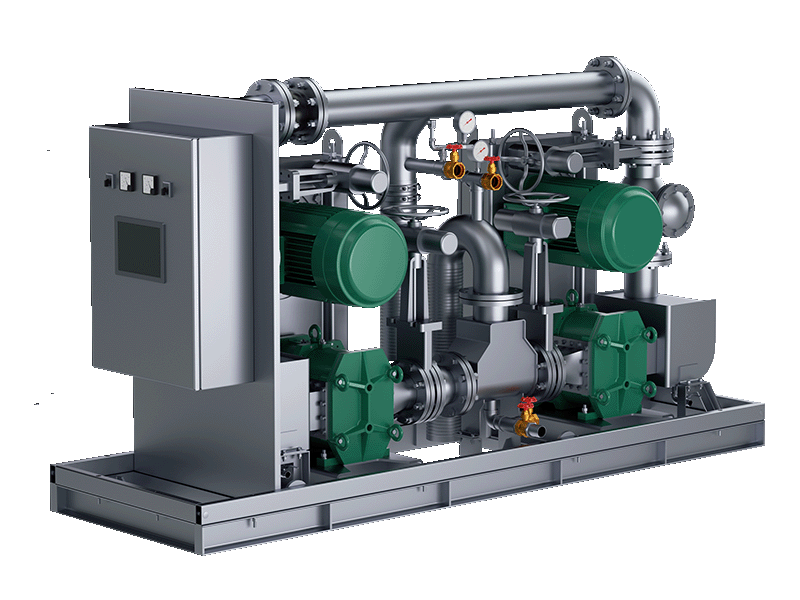

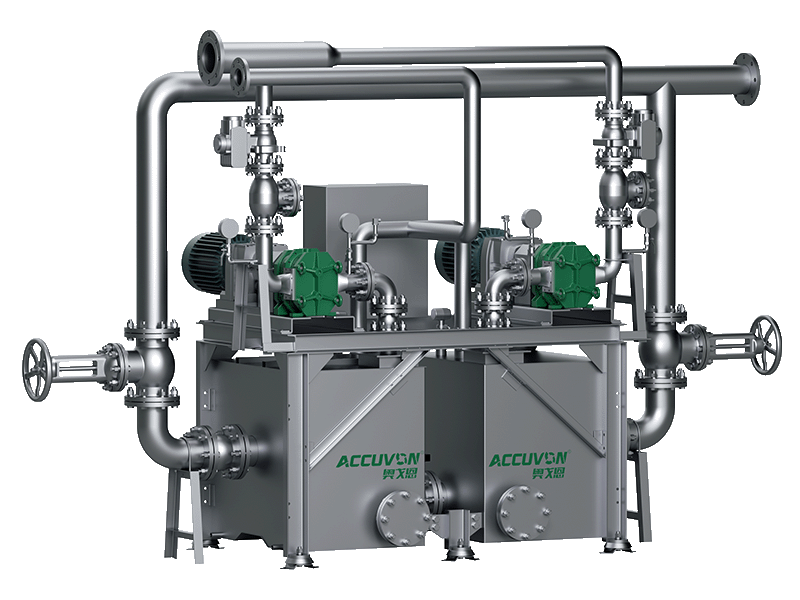

1. Wastewater Treatment : Rotary pumps are extensively used in wastewater treatment plants for sludge transfer, thickening, and dewatering processes. Their ability to handle high solids content and viscous sludges makes them ideal for maintaining efficient operation in sewage treatment facilities.

2. Chemical Processing: In chemical industries, rotary pumps play a critical role in transferring various chemicals, ensuring accurate dosing and mixing in production processes. Their compatibility with a wide range of chemicals and precise flow control capabilities are highly valued.

3.Environmental Remediation: For air pollution control, rotary pumps are employed in scrubber systems to remove contaminants from industrial exhaust gases. They assist in conveying scrubbing liquids and maintaining optimal conditions for effective pollutant removal.

In conclusion, rotary pumps are pivotal in the environmental industry for their efficiency, adaptability, and robust performance. Their widespread applications in wastewater treatment, chemical processing, and environmental remediation underscore their importance in ensuring sustainable and effective environmental management practices. As environmental regulations become more stringent and technology advances, rotary pumps continue to evolve, promising even greater contributions to environmental protection and resource conservation.